An anti-floating system for underground structures integrating corridor drainage and fertilizer tank anti-seepage

A technology for underground structures and collection corridors, applied in infrastructure engineering, buildings, protection devices, etc., can solve the problems of surrounding buildings, easy blockage of underground passages, difficult maintenance, etc., to ensure strength and rigidity, and reduce the possibility of blockage performance, durability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

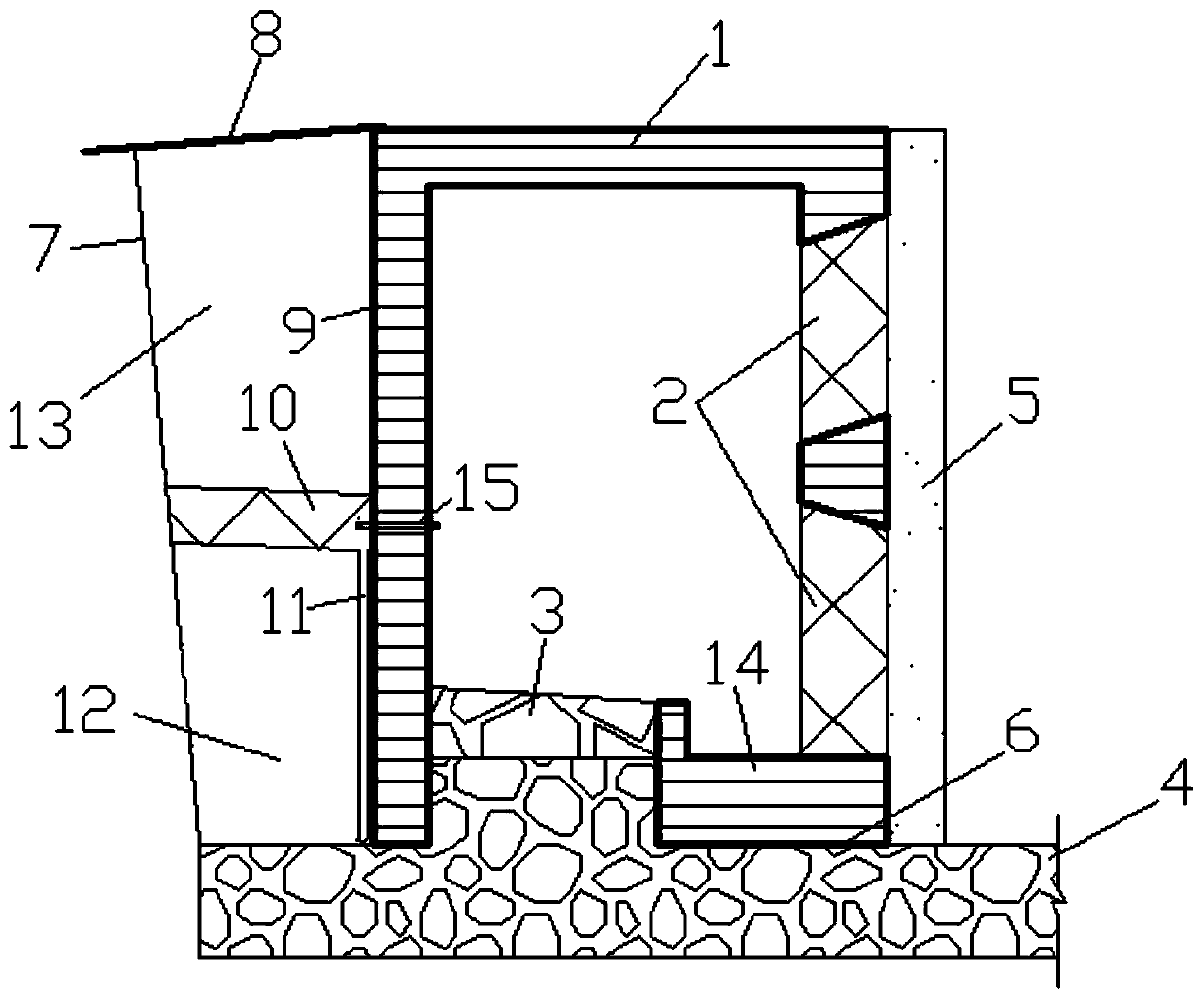

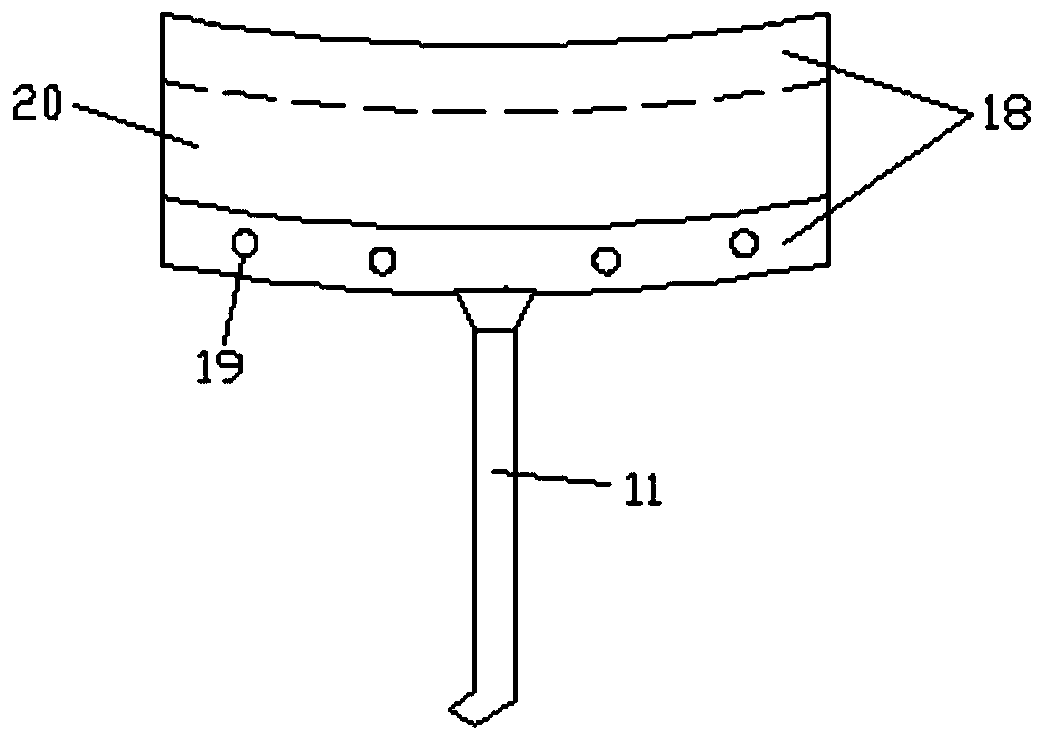

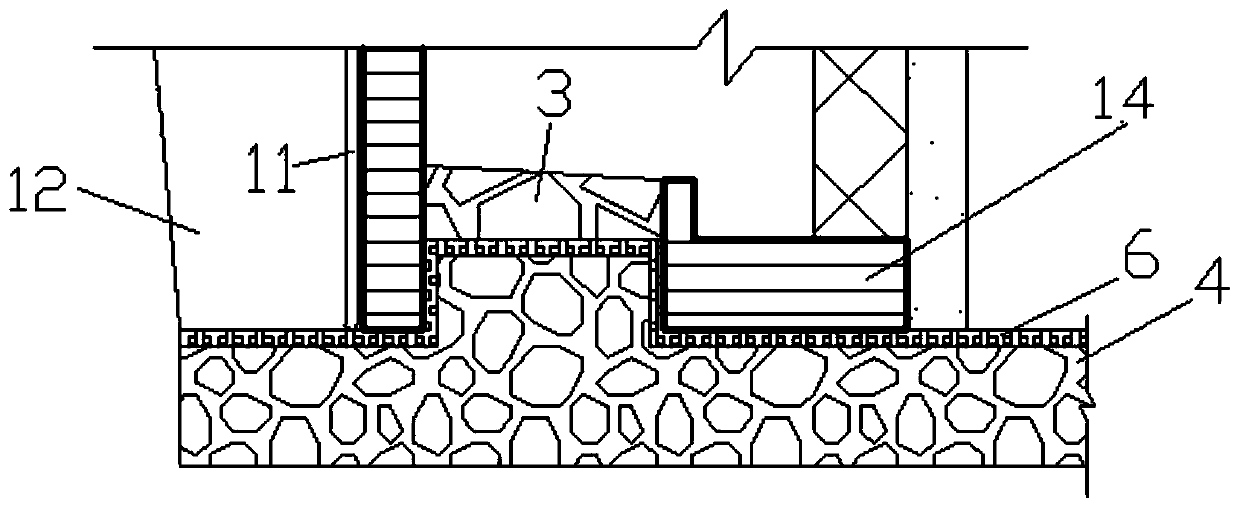

[0026] Such as Figure 1-4 As shown, the uplift pressure on a certain basement is generally greater than the self-weight of the structure, so anti-floating treatment is required. The roof 1, the bottom 14, the building exterior wall 9 and the side concrete window wall 2 constitute a corridor, and a continuous crushed stone hydrophobic cushion 4 is laid under the basement floor 14, extending to the bottom of the corridor, with a thickness of 400 mm. The function of the crushed stone hydrophobic cushion 4 is mainly to make the groundwater under the base plate 14 flow into the corridor smoothly. In order to prevent the cement slurry from penetrating into the gravel hydrophobic cushion 4 during concrete pouring, a geomembrane 6 is arranged at the contact surface between the bottom plate 14 and the gravel hydrophobic cushion 4 . The corridor adopts reinforced concrete frame structure. Water outlet 15 is laid in the middle part of building exterior wall 9 and is used for connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com