Muffler for compressor and compressor having the same

A muffler and compressor technology, applied in the field of compressors, can solve the problems of reduced compressor performance, increased refrigerant flow resistance, reduced size, etc., to prevent the increase of specific volume, improve compressor performance, and reduce suction loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Next, the silencer for a compressor and the compressor having the silencer for a compressor according to the present invention will be described in detail using an embodiment shown in the drawings.

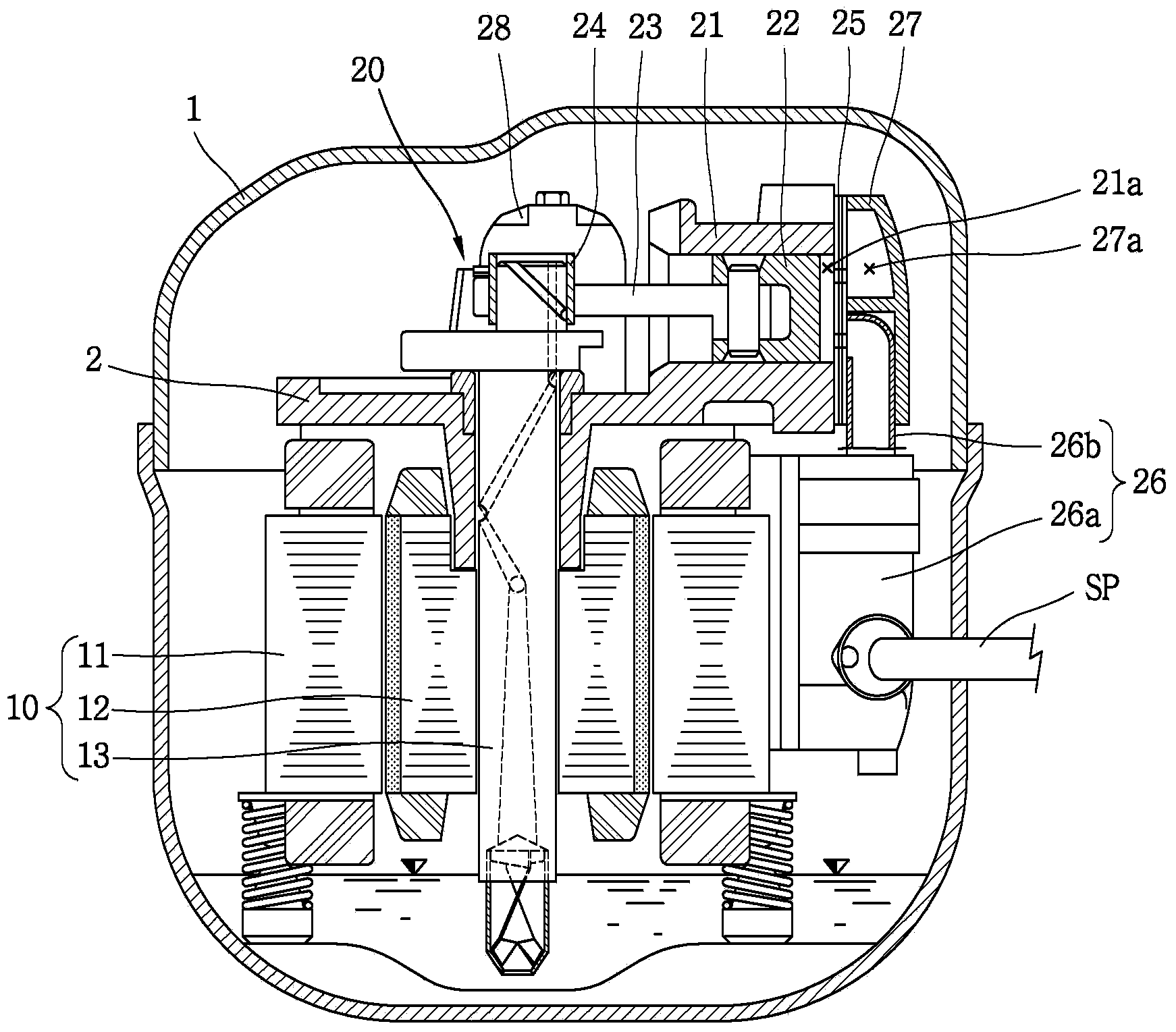

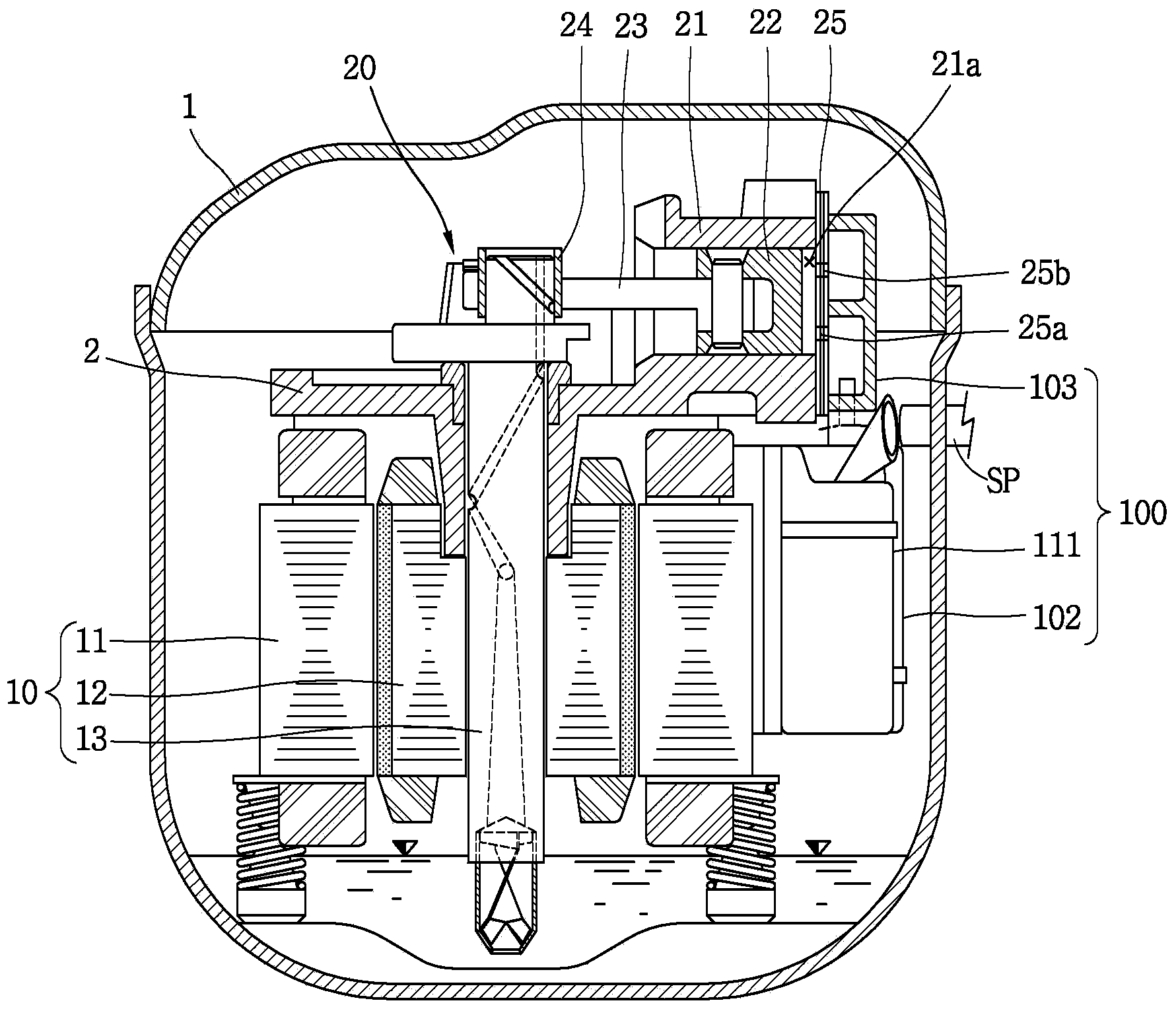

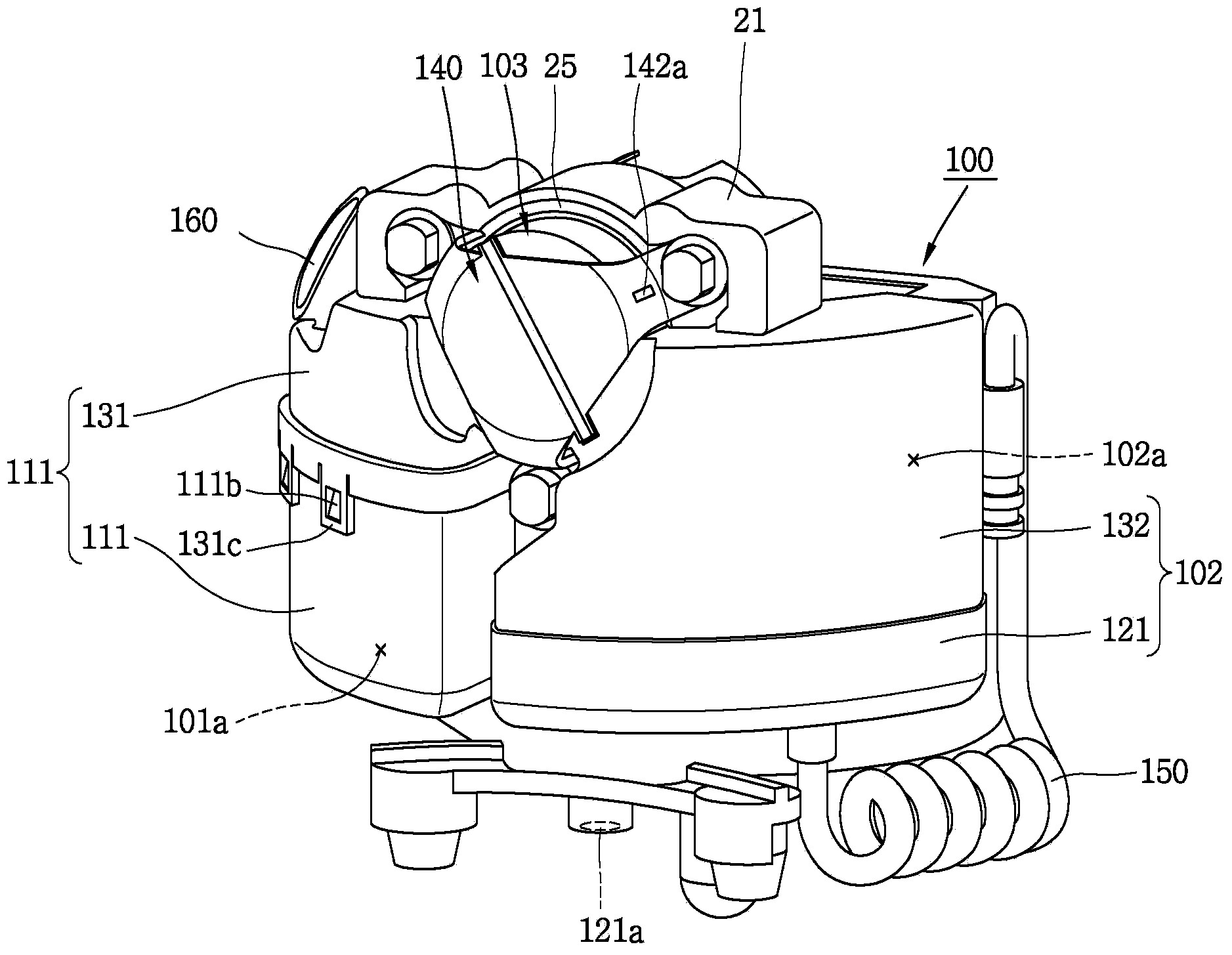

[0046] figure 2 is a longitudinal sectional view showing a reciprocating compressor having an integrated muffler of the present invention, image 3 is viewed from the front figure 2 A perspective view of the one-piece muffler, Figure 4 is to be used for fixing on the compression part figure 2 The fixed member of the one-piece muffler is shown in perspective view separated, Figure 5 is viewed from the back figure 2 A perspective view of the one-piece muffler.

[0047] Such as figure 2 As shown, the reciprocating compressor with the muffler for the compressor of the present invention may include: a casing 1; an electric part 10, which is arranged in the inner space of the above-mentioned casing 1, and is composed of a stator 11, a rotor 12 and a rotating shaft 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com