Automated metal surface treatment device

A technology of metal surface treatment and transmission wheel, which is applied to grinding drive devices, metal processing equipment, manufacturing tools, etc., can solve the problems of unstable wire drawing strength, influence on yield, uneven wire flow, etc., to ensure wire drawing quality, guarantee The effect of machining quality and straightness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

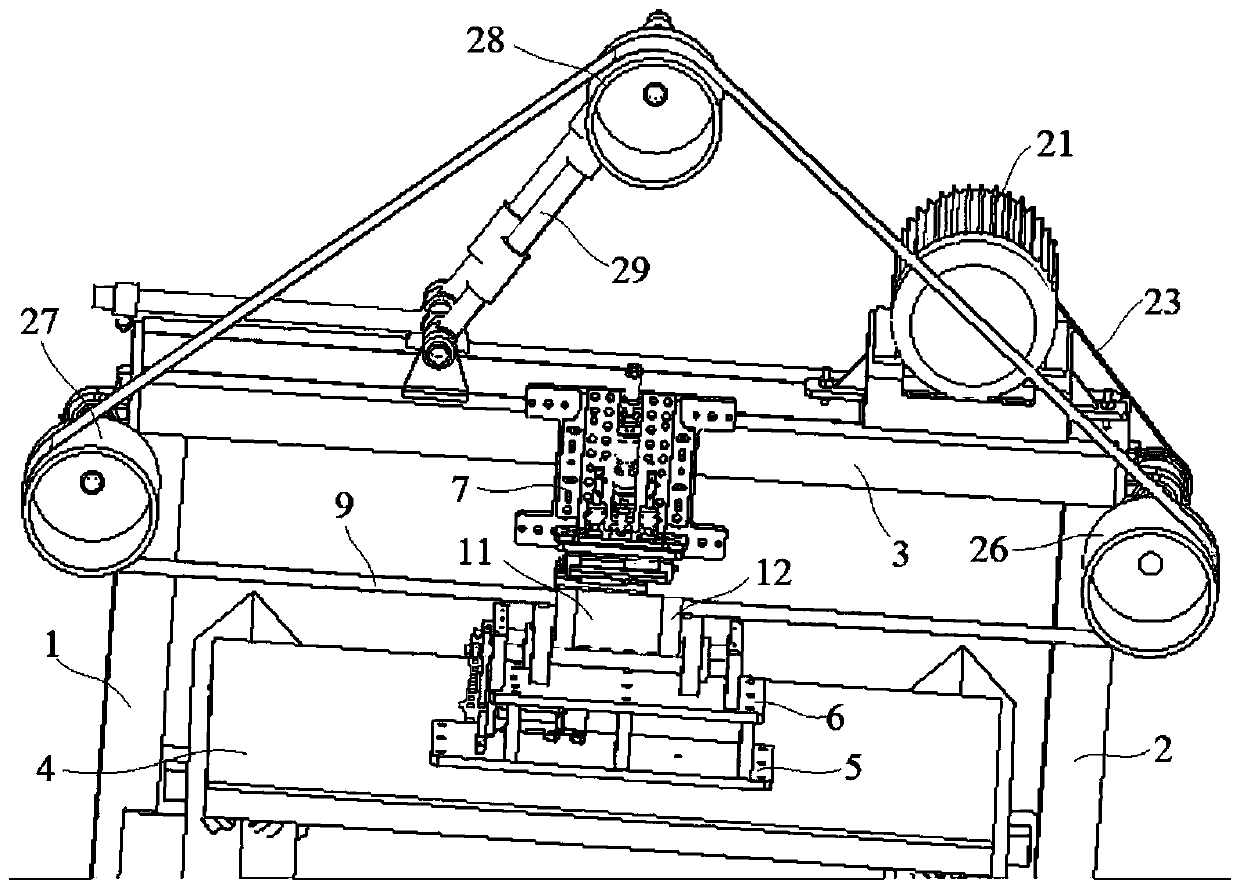

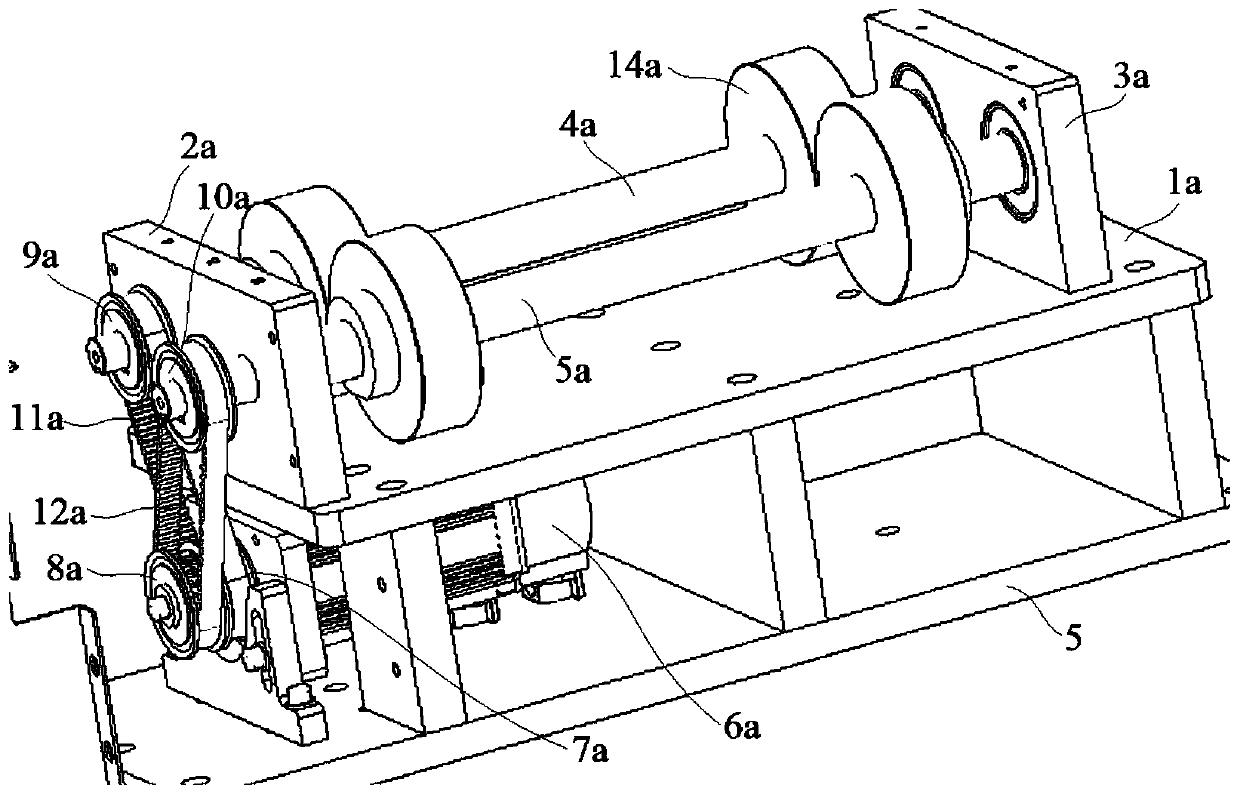

[0029] Embodiment 1: An automatic metal surface treatment device, including a left vertical plate 1, a right vertical plate 2, a beam plate 3, a carrier plate 4, a base plate 5, a clamp seat 6, a pressing mechanism 7 and an abrasive belt 9, the left The vertical plate 1 and the right vertical plate 2 are arranged in parallel, the beam plate 3 bridges the left vertical plate 1 and the right vertical plate 2, and the two ends of the lower surface of the beam plate 3 are respectively fixed to the upper surfaces of the left vertical plate 1 and the right vertical plate 2 connection, the two sides of the carrier plate 4 are installed and connected with the left vertical plate 1 and the right vertical plate 2 respectively, the base plate 5 is installed on the upper surface of the carrier plate 4, and the pressing mechanism 7 is installed on the front side of the beam plate 3, so The fixture seat 6 is installed above the base plate 5, the abrasive belt 9 is horizontally arranged direc...

Embodiment 2

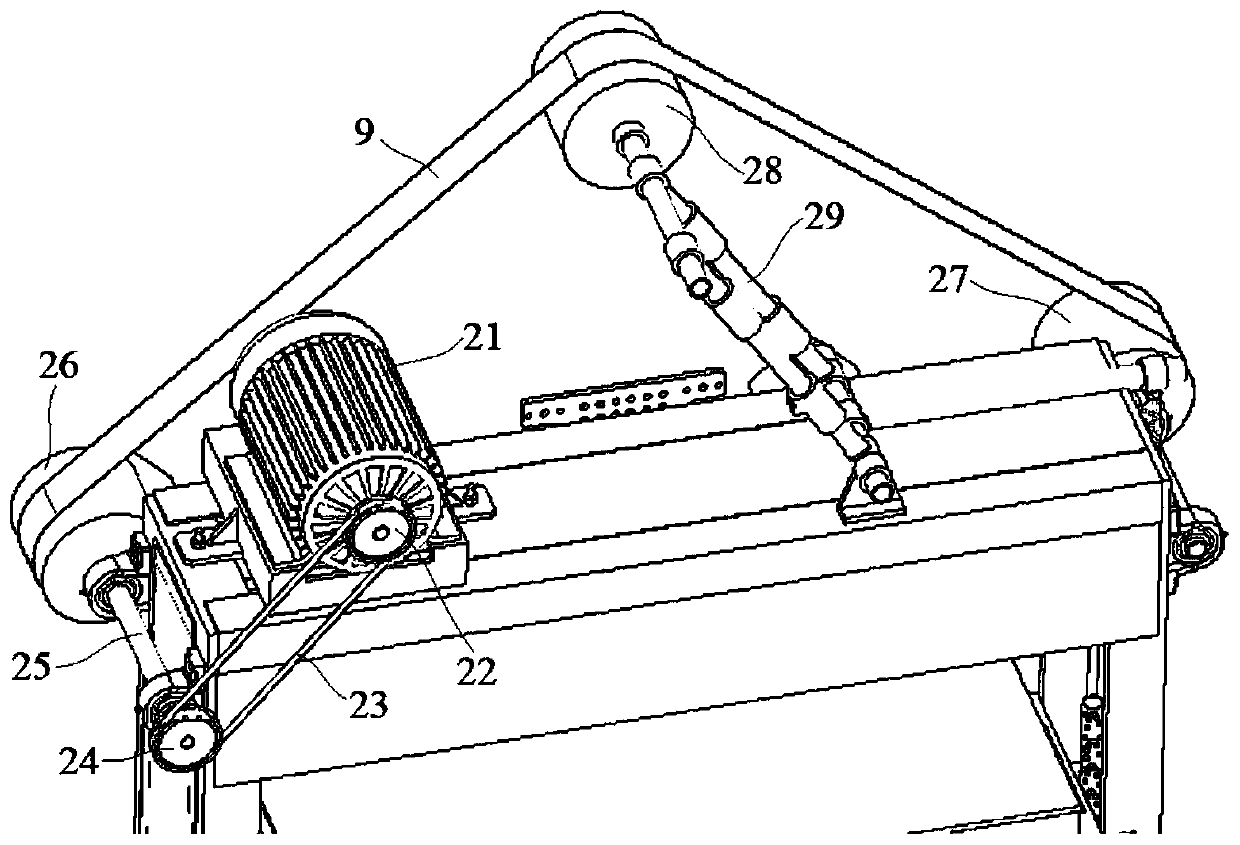

[0035] Embodiment 2: An automatic metal surface treatment device, including a left vertical plate 1, a right vertical plate 2, a beam plate 3, a carrier plate 4, a base plate 5, a clamp seat 6, a pressing mechanism 7 and an abrasive belt 9, the left The vertical plate 1 and the right vertical plate 2 are arranged in parallel, the beam plate 3 bridges the left vertical plate 1 and the right vertical plate 2, and the two ends of the lower surface of the beam plate 3 are respectively fixed to the upper surfaces of the left vertical plate 1 and the right vertical plate 2 connection, the two sides of the carrier plate 4 are installed and connected with the left vertical plate 1 and the right vertical plate 2 respectively, the base plate 5 is installed on the upper surface of the carrier plate 4, and the pressing mechanism 7 is installed on the front side of the beam plate 3, so The fixture seat 6 is installed above the base plate 5, the abrasive belt 9 is horizontally arranged direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com