Dust remover for grain collecting vehicle and operation method thereof

A technology for collecting vehicles and dust collectors, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles. It can solve problems such as incomplete filtration and clogging, and achieve material cost savings, easy washing or replacement, and overall weight reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

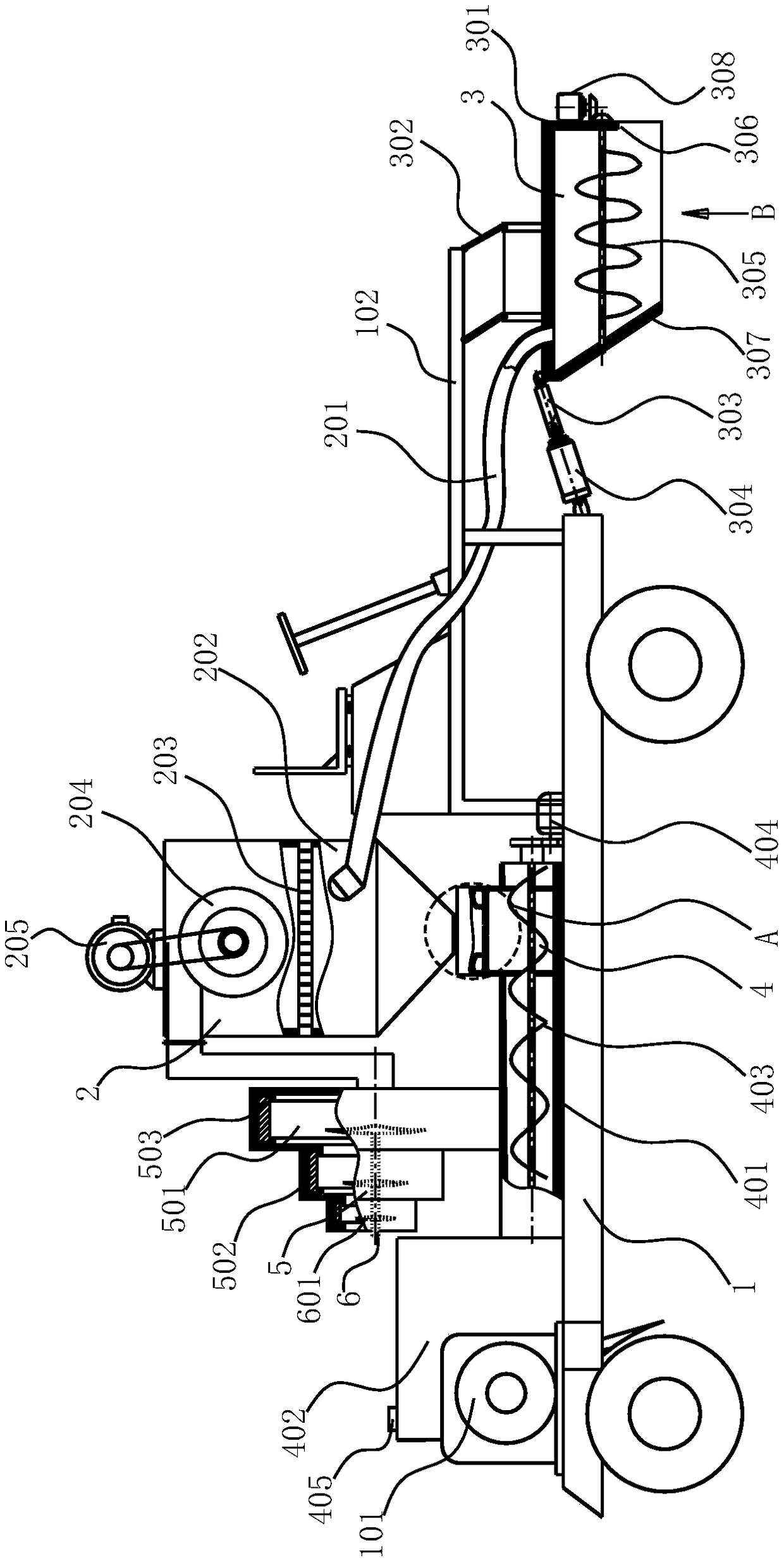

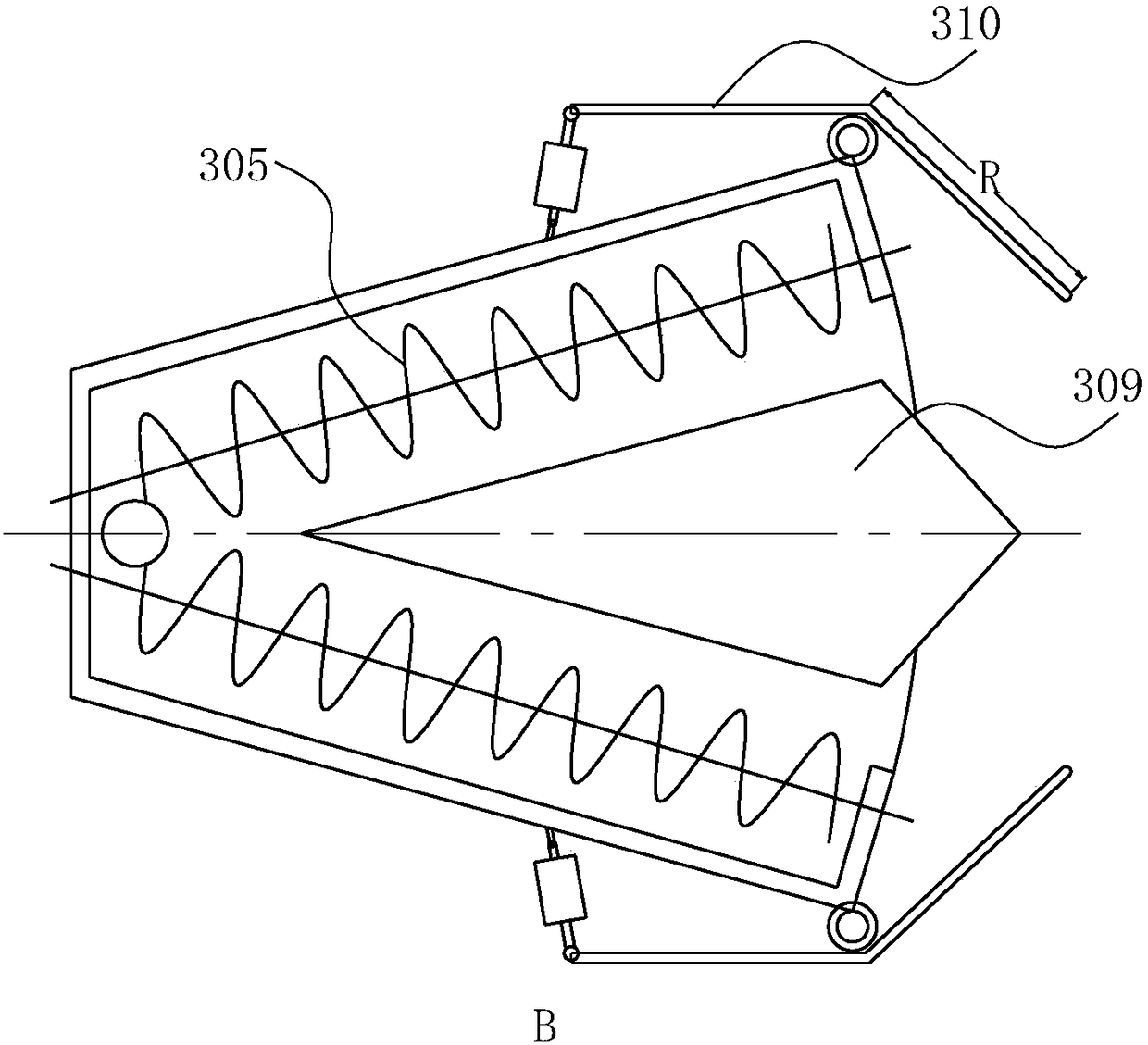

[0057] The invention is shown by way of example and is highly simplified as Figure 1 to Figure 5 Shown:

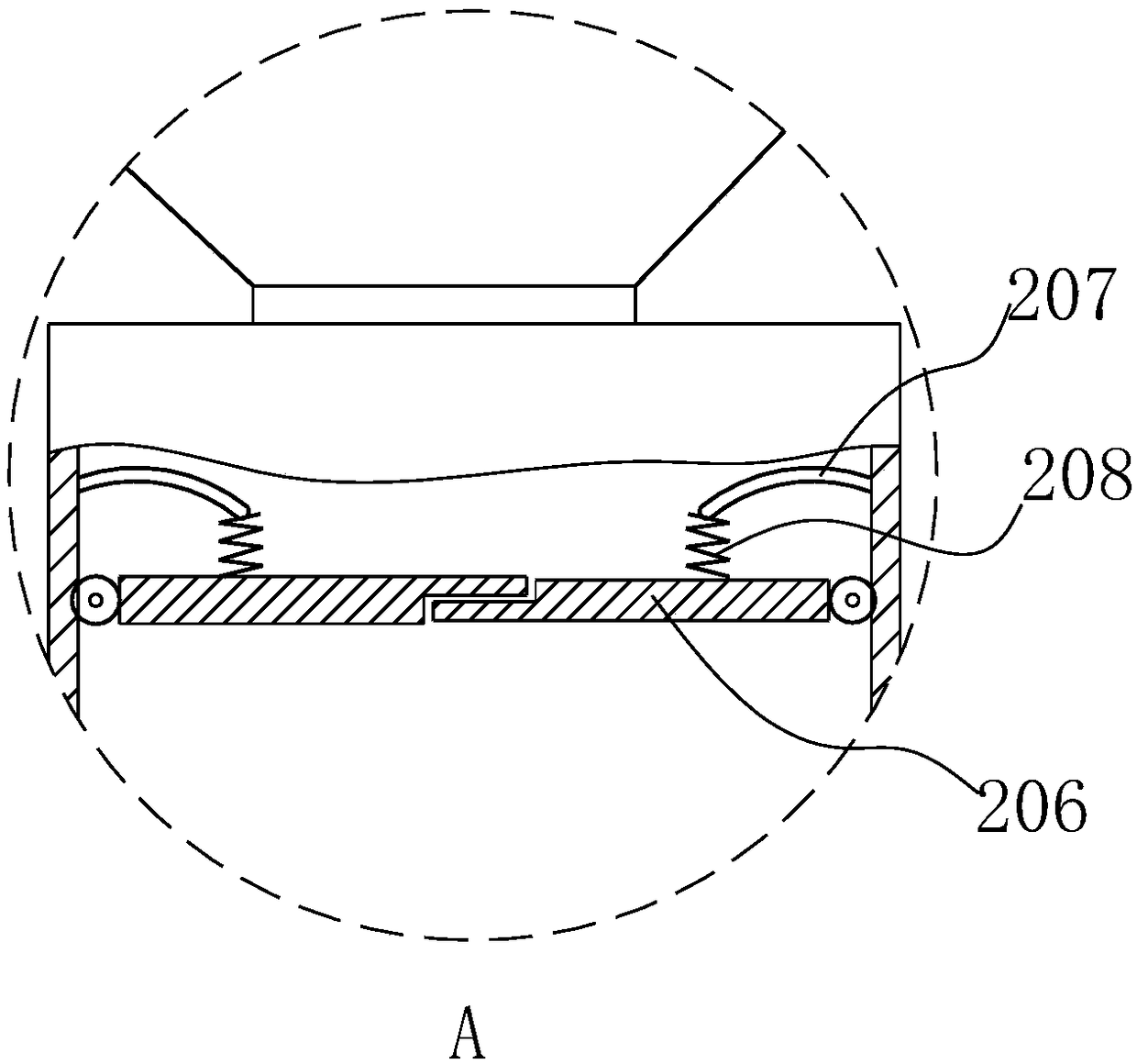

[0058] In the prior art, the air locker is usually used to separate the grain from the separation bin 202, but the air locker needs to be driven separately, which increases the load of the generator on the one hand, and on the other hand increases the mass of the vehicle and increases the engine load. The power requirement is not conducive to energy saving and emission reduction, and it goes against the trend of lightweight vehicle design.

[0059] Furthermore, during the rotation of the blades of the air locker, the grain particles located between the blades and the inner wall of the air locker will be crushed, which is not conducive to ensuring the integrity of grain processing, and the crushed grain is more likely to deteriorate and become moldy. Too many crushed grain particles will affect the grain storage quality and quality assurance period of the entire granary. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com