A double mover linear compressor

A linear compressor and double mover technology, applied in the field of compressors, can solve problems such as difficult to eliminate and strong penetration, and achieve the effects of increased stability, small left and right axial vibration, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

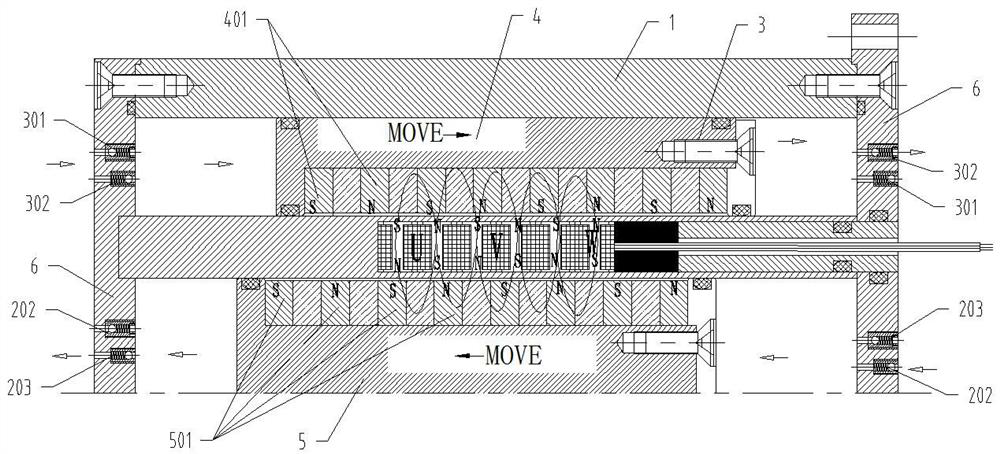

[0028] like Figure 1 to Figure 4 As shown, a double mover linear compressor includes an outer shell 1, in which a cylinder 2 is arranged along the axis, and the two form a cylinder ring chamber 3; a piston A4 is arranged in the cylinder ring chamber 3, and a cylinder There is a piston B5 inside the cylinder 2; the left and right ends of the cylinder ring cavity 3 and the cylinder 2 are closed by the end cover 6, and the left and right ends of each cavity are provided with corresponding inlet valves and outlet valves. Fluid compression is performed by driving the left and right movements of the piston A4 and the piston B5.

[0029] In this scheme, if figure 1 As shown, a plurality of permanent magnets A401 are arranged at intervals on the piston A4, a plurality of permanent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com