a kind of nh 2 -rgo/mno 2 Composite materials, preparation methods and applications

A composite material, nh2-rgo technology, applied in nanotechnology for materials and surface science, hybrid capacitor electrodes, nanotechnology, etc., can solve the problems of poor overall performance and poor conductivity of the structure, and achieve regular morphology, Improvement of electrical conductivity and reduction of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation process of this embodiment is as follows:

[0025] (1) Prepare graphite oxide by the Hummers method, wash the obtained graphite oxide solution with 1:1 ethanol and deionized water until the supernatant is colorless, and disperse it in deionized water to obtain an aqueous graphite oxide solution of 0.5 to 1.0 g / L ;

[0026] (2) Stir 20 mL of 1 g / L graphite oxide aqueous solution and 50 mL of dimethylformamide in a water bath at 35 °C for 1 hour, then add 100 mL of p-phenylenediamine solution to the above reaction, and raise the temperature to 80 °C , reflux and stir for 10 hours, wash the obtained reactant with ethanol and deionized water until the supernatant is colorless and neutral, disperse the obtained precipitate into deionized water, and obtain aminated reduced graphite oxide with a concentration of 1 g / L ene NH 2 -rGO aqueous solution; the concentration of p-phenylenediamine solution is 3g / L, sonicated in an ultrasonic environment for 30-60 minu...

Embodiment 2

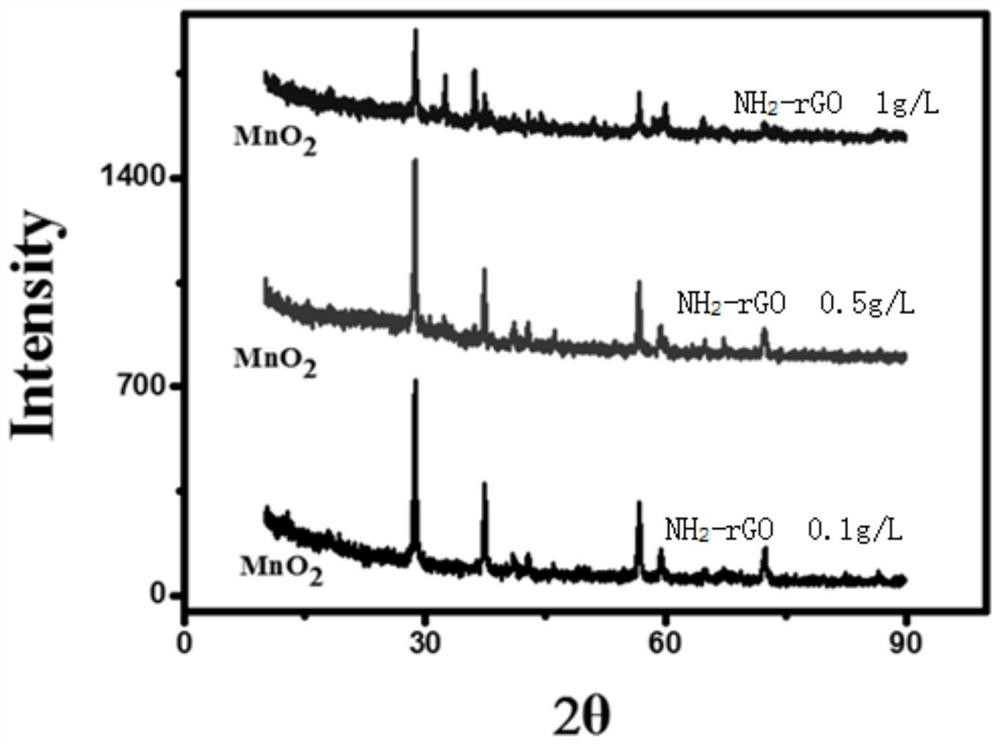

[0029] In this embodiment, 0.395 g of potassium permanganate was added to 100 mL of deionized water to obtain a 0.025 mol / L potassium permanganate aqueous solution, and 10 mL of aminated reduced graphene oxide NH with a concentration of 0.1 g / L was taken. 2 -rGO aqueous solution mixed with 40mL potassium permanganate aqueous solution, ultrasonicated for more than 30 minutes, transferred to the reaction kettle for hydrothermal reaction, the temperature of the hydrothermal reaction was 180°C, and the time was 15 hours. Wash with water and ethanol solution until the supernatant is colorless, dry the precipitate in vacuum at 60°C, and grind to obtain NH 2 -rGO / MnO 2 powder.

[0030] Other implementations are the same as in Example 1.

Embodiment 3

[0032] In this embodiment, 0.395 g of potassium permanganate was added to 100 mL of deionized water to obtain a 0.025 mol / L potassium permanganate aqueous solution, and 10 mL of aminated reduced graphene oxide NH with a concentration of 0.5 g / L was taken. 2 -rGO aqueous solution mixed with 40mL potassium permanganate aqueous solution, ultrasonicated for more than 30 minutes, transferred to the reaction kettle for hydrothermal reaction, the temperature of the hydrothermal reaction was 180°C, and the time was 15 hours. Wash with water and ethanol solution until the supernatant is colorless, dry the precipitate in vacuum at 60°C, and grind to obtain NH 2 -rGO / MnO 2 powder.

[0033] Other implementations are the same as in Example 1.

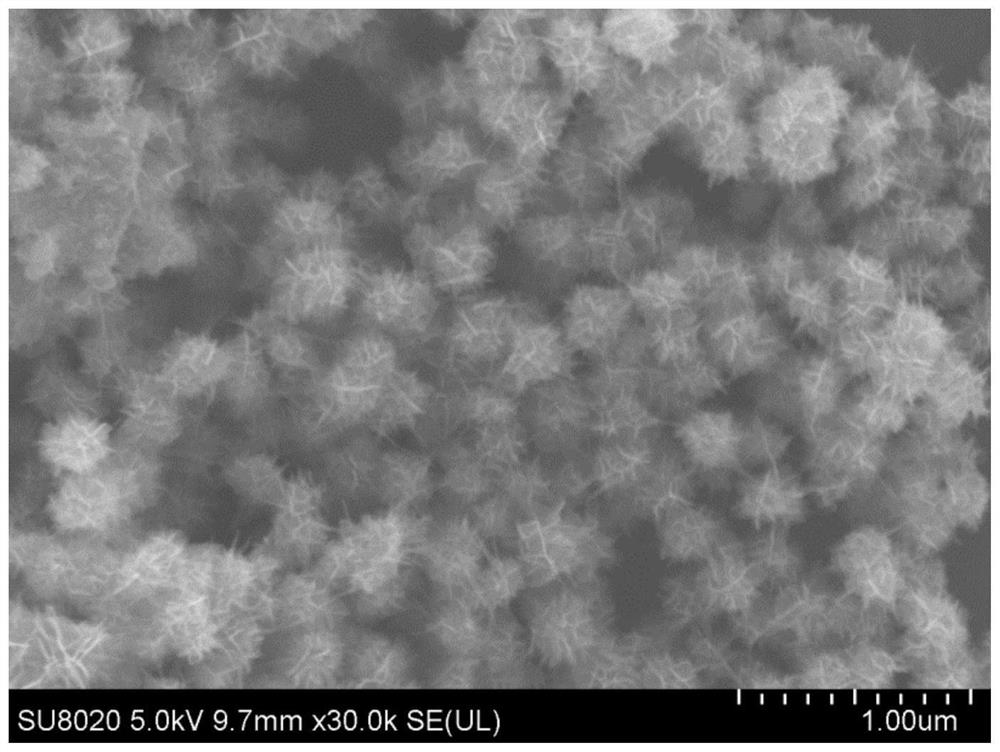

[0034] The composite material that embodiment 1 is prepared carries out SEM analysis as figure 1 As shown, it can be seen from the figure that the microscopic morphology of the composite material is good, uniform and orderly, and the dispersion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com