Solar cell production equipment management system and realization method thereof

A technology for solar cells and production equipment, which is applied in manufacturing computing systems, electrical digital data processing, and data processing applications. The effect of fast communication and paper saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

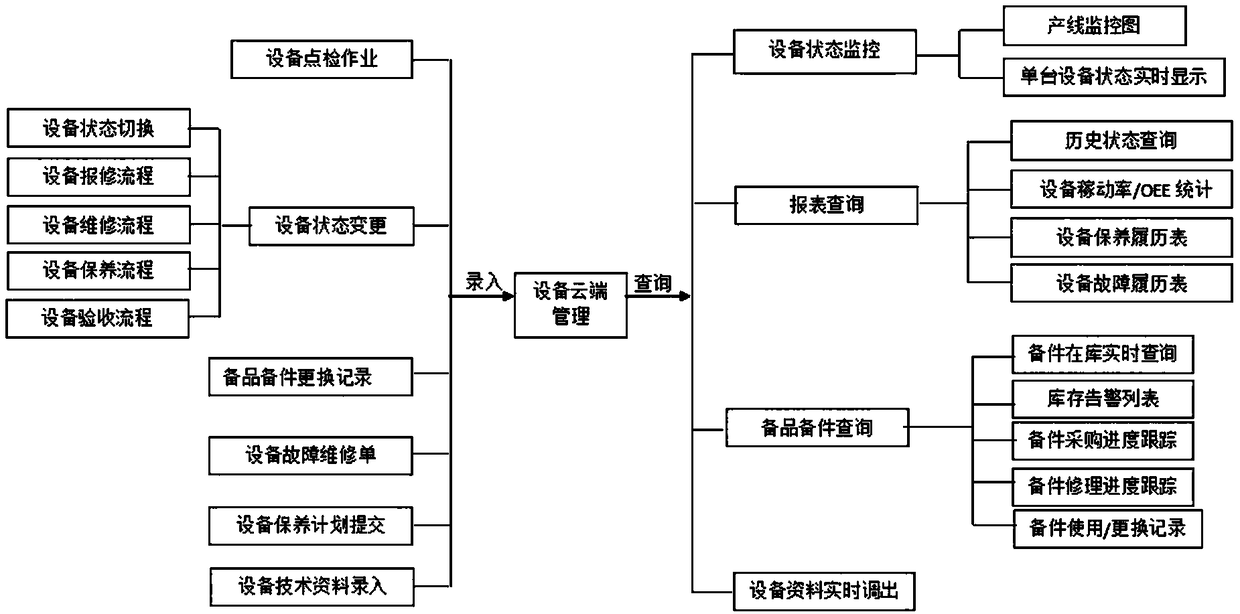

[0034]A solar cell production equipment management system, including an equipment management server, used to manage data such as inspection, maintenance, repair, acceptance, spare parts and spare parts of each equipment in the factory, which includes an equipment inspection unit, an equipment maintenance unit, an equipment maintenance unit and Equipment acceptance unit; the equipment management server also has equipment status switching function, the switchable equipment status includes equipment production, standby, engineering test and unplanned; there is also an equipment status monitoring unit, which includes the production line monitoring module and each equipment State monitoring module; the equipment management server is also equipped with a query module for querying various reports, including equipment utilization rate, equipment comprehensive efficiency statistics table, equipment failure history table, equipment maintenance history table and equipment spare parts repla...

Embodiment 2

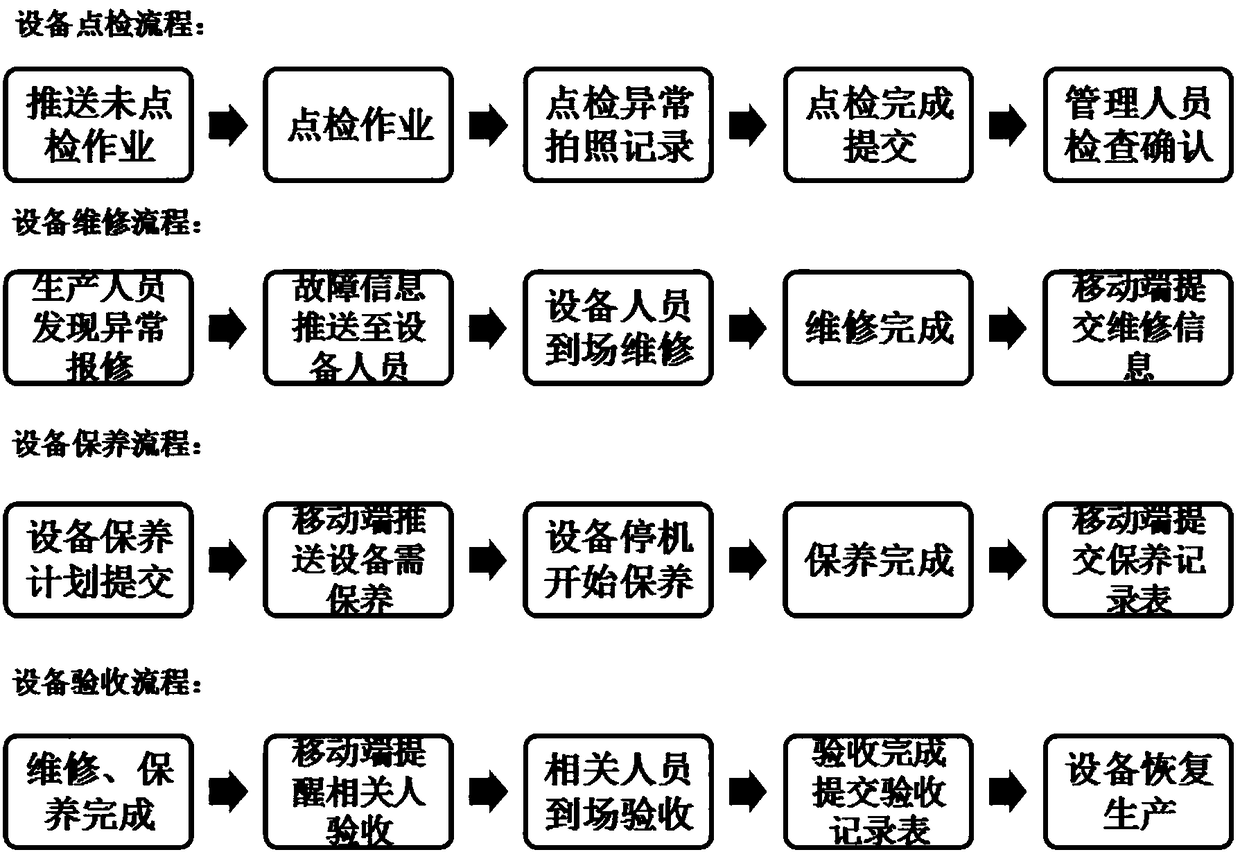

[0041] A method for realizing a production equipment management system. The basic data information of all production equipment is entered into the equipment management server. In the unit, corresponding inspection, maintenance and repair plans are formulated according to functional requirements; the mobile terminal feeds back the inspection, warranty, maintenance, and acceptance status of each device to the equipment management server in real time, and the corresponding functional modules of the equipment management server perform data processing. Then feed back to the corresponding staff through the mobile terminal.

Embodiment 3

[0043] The specific workflow of using this system to report for repairs is: when an equipment failure occurs, the production line staff will modify the equipment status to failure through the mobile terminal (after modification, the status of the equipment will automatically change to "unplanned shutdown status"), and the equipment failure The information will be pushed to the mobile terminal of the equipment maintenance personnel through the system, and the equipment personnel will go to the site for maintenance immediately after receiving the information; at the same time, the production line staff will record the fault phenomenon through the camera function of the mobile terminal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com