Novel level gauge with i angle detection function

A level and functional technology, which is applied in the field of geodetic surveying and engineering surveying, can solve the problems of energy and time consumption of surveyors, reduced accuracy of measurement results, and high manufacturing costs, so as to improve operation accuracy and work efficiency, improve detection accuracy and efficiency, The effect of improving the level of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

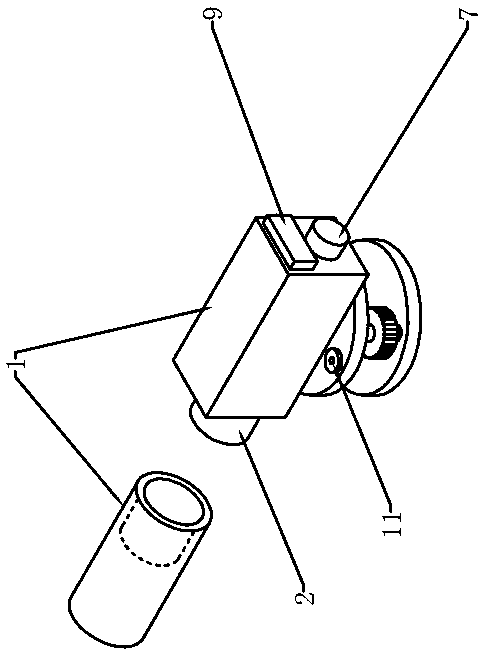

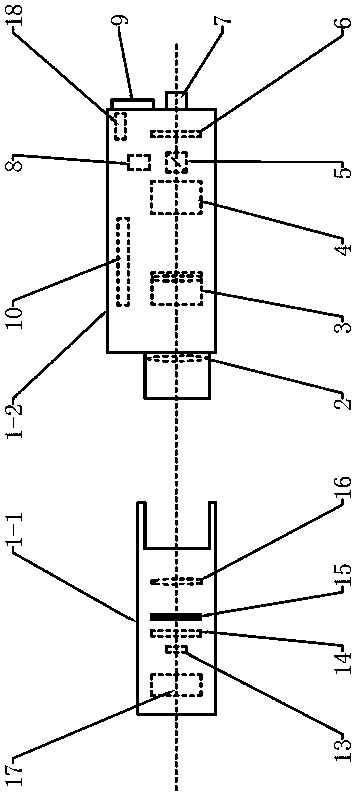

[0015] Such as figure 1 , 2 As shown: as in the prior art, a housing 1 is provided, and an objective lens 2 with the same center line, a focusing lens 3, an automatic horizontal line of sight compensator 4, a beam splitter 5, and a crosshair reticle 6 are arranged in the housing 1 , eyepiece 7, electronic reading device 8 (that is, a CCD image decoding and reading device used in conjunction with the coded leveling scale), display and control terminal 9 and power supply 10, and a leveling device 11 is provided on the outer side of the housing 1, and the present embodiment 1 The level 11 adopts a circular level bubble. Different from the prior art, the housing 1 is formed by the movable connection of the left housing 1-1 and the right housing 1-2, which can be threaded or plugged, and should be easy to install and disassemble. The objective lens 2, focusing lens 3, automatic horizontal line of sight compensator 4, beam splitter 5, crosshair reticle 6, eyepiece 7, electronic re...

Embodiment 2

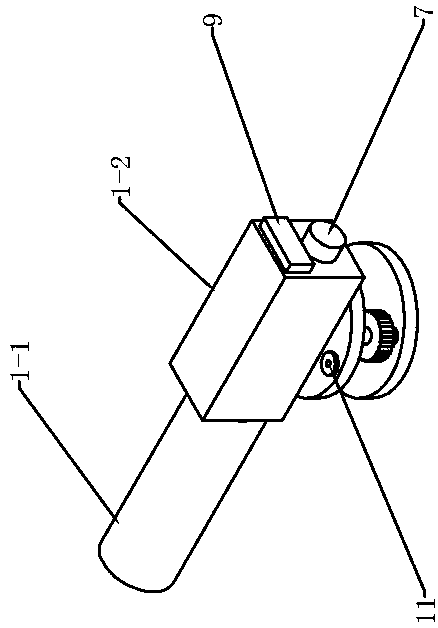

[0022] Such as Figure 4 , 5 As shown: as in the prior art, a housing 1 is provided, and an objective lens 2 with the same center line, a focusing lens 3, an automatic horizontal line of sight compensator 4, a beam splitter 5, and a crosshair reticle 6 are arranged in the housing 1 , eyepiece 7, electronic reader 8 (that is, a CCD image decoding and reading device used in conjunction with the coded leveling scale), display and control terminal 9 and power supply 10, and a level 11 (pipe level) is provided on the outer side of the housing 1. The vial 11 of the present embodiment 2 adopts a tube level bubble. Different from the prior art, there is an alarm 18 connected to the display and control terminal 9, and the built-in light source 13 whose center line is perpendicular to the center line of the objective lens 2, scattering glass 14, and vertical transparent miniatures are sequentially arranged on the objective lens 2 from top to bottom. Coding scale 15 and convex lens 16 ...

Embodiment 3

[0029] Such as Figure 6 Shown: the structure is basically the same as that of Embodiment 2, the difference is that the level 11 adopts electronic bubbles, the center line of the built-in light source 13, the scattering glass 14, the vertical transparent microcode scale 15 and the convex lens 16 is parallel to the center line of the objective lens 2, Reflector 21 is provided on the center line of convex lens 16, beam splitter 19 is provided on the reflected light path of reflector 21, the split light beam inside beam splitter 19 strikes objective lens 2, and the outside of beam splitter 19 is provided with optical path switching device 20.

[0030] Working process is with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com