Condensate water waste heat recovery system

A waste heat recovery system and condensate water technology, applied in indirect heat exchangers, heat exchange equipment, heat exchanger types, etc., can solve the problems of underutilization of condensate water heat, damage to temperature structure, pollution, etc. Availability, improve energy efficiency, the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

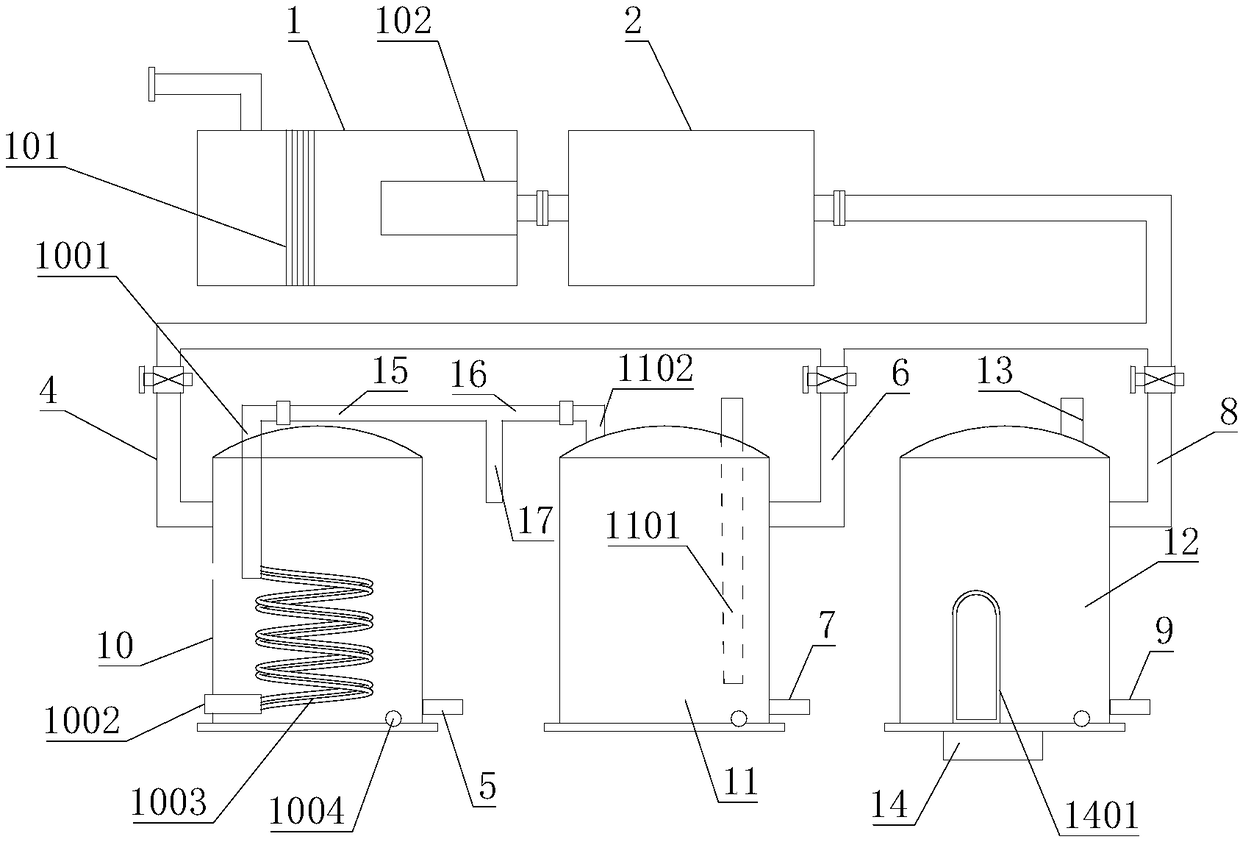

[0039] Such as figure 1 As shown, this embodiment discloses a condensate waste heat recovery system, including an antifouling treatment system and a heat recovery system. The water inlet of the antifouling treatment system is connected to the condensate pipe, and the water outlet of the antifouling treatment system is connected to the heat recovery system.

[0040] Specifically, the heat recovery system includes a hot air flow device and a double steam flow device separately communicated with the antifouling treatment system.

[0041] Hot air flow devices include dry heat devices and humid heat devices.

[0042] The dry heat device includes a first water collecting tank 10, on which a first water inlet 4 and a first water outlet 5 are arranged, the first water inlet 4 is connected to the water outlet of the antifouling treatment system, and the first water outlet 5 connected to the water return tank; the first water collecting tank 10 is also provided with a first air inlet 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com