Porous graphite sleeve combination device of batch sintering and painting die

A combined device and porous graphite technology, applied in the field of painting molds, can solve problems such as unguaranteed strength of the sintered body, unbalanced density of the sintered body, and hidden dangers in the quality of the painting mold, achieving strength assurance, eliminating quality problems, and temperature uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Porous graphite sleeve combination device

[0052] A porous graphite sleeve assembly device for batch sintering paint moulds, the assembly device includes the following components:

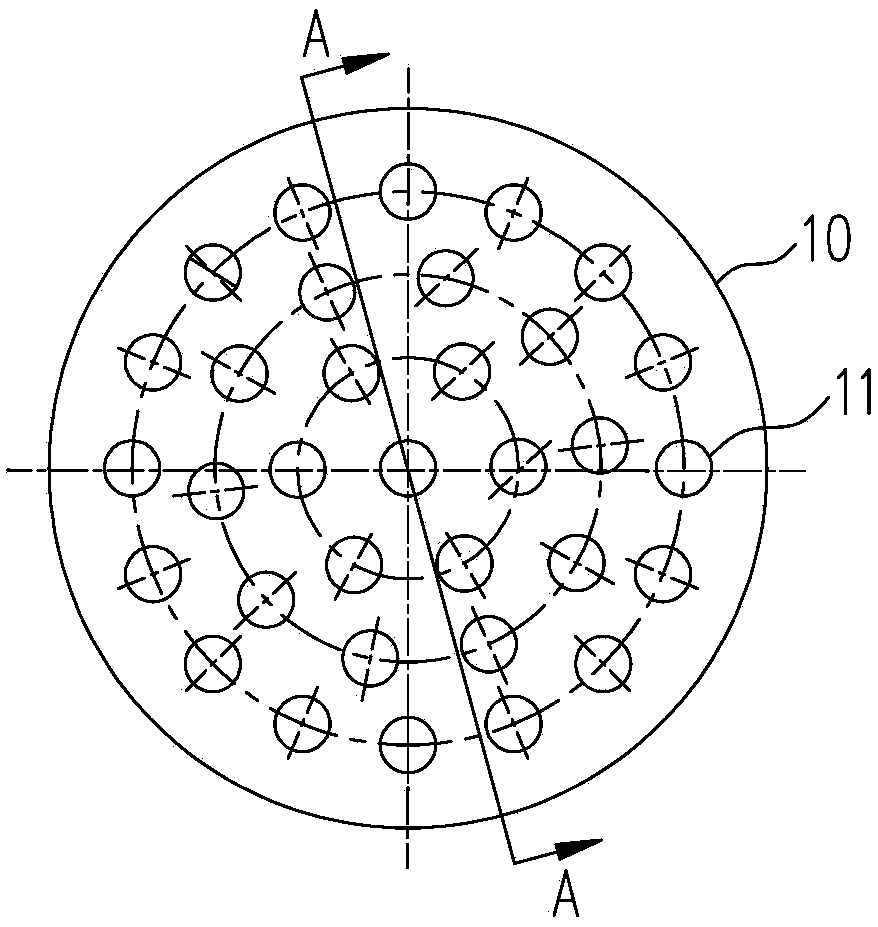

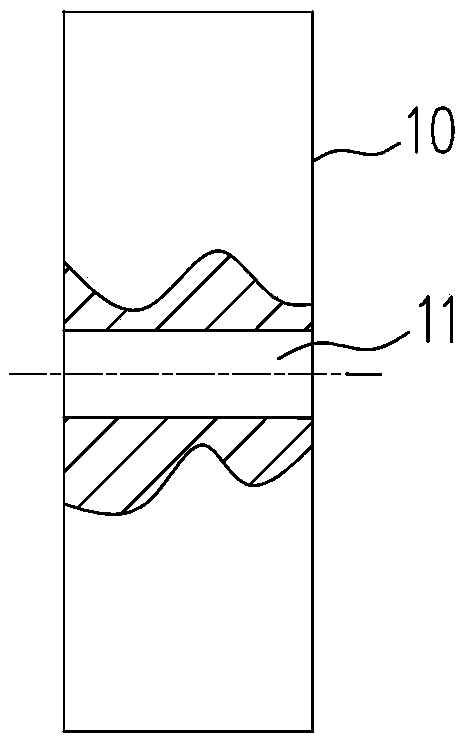

[0053] Graphite sleeve 10, described graphite sleeve 10 is integral shape, and graphite sleeve 10 is provided with a plurality of graphite holes 11 that run through its body from top to bottom, and the central axis of this plurality of graphite holes 11 is parallel to each other, as figure 1 , figure 2 shown;

[0054]Clamps, the number of the clamps is adapted to the number of graphite holes 11 , and the clamps are used to clamp and fix the body 40 to be sintered in the graphite holes 11 .

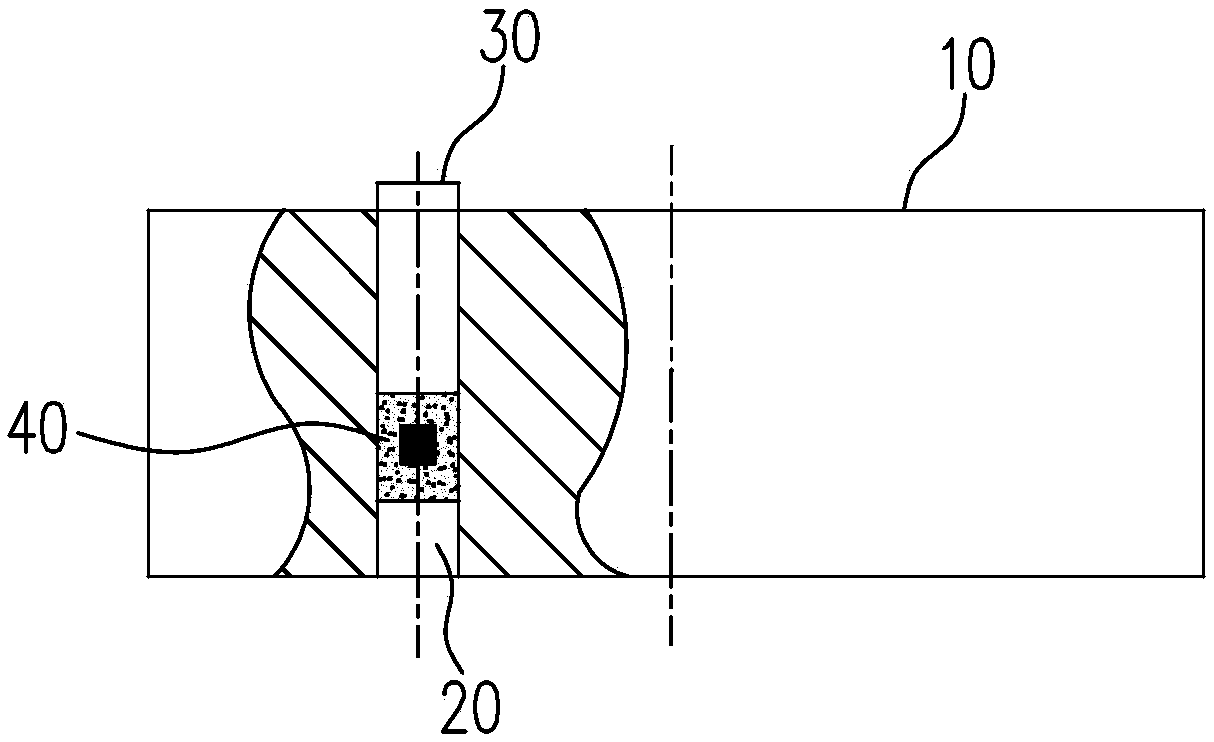

[0055] Such as image 3 As shown, the fixture includes graphite pad rods 20 and graphite pressure rods 30 that are arranged on both sides of the body to be sintered 40, and graphite pad rods 20 and graphite pressure rods 30 cooperate with each other in pairs; the graphite pad rods 20 are arranged on...

Embodiment 2

[0064] Preparation Technology of Synthetic Diamond Sintered Body

[0065] In this preparation process, the porous graphite sleeve combination device of the batch sintered paint mold as described in Example 1 is used, that is, the graphite sleeve 10 is in a monolithic shape, and the graphite sleeve 10 is provided with a plurality of holes through it from top to bottom. The graphite holes 11 of the body, the central axes of the plurality of graphite holes 11 are parallel to each other;

[0066] This preparation process comprises the steps:

[0067] S1. If Image 6 As shown, the graphite backing rods 20 are respectively packed into a plurality of graphite holes 11 of the graphite sleeve 10, the quantity of the graphite backing rods 20 matches the quantity of the graphite holes 11, and the graphite backing rods 20 are fixed on the graphite in hole 11;

[0068] S2. If Figure 7 As shown, the bottom sintering powder 41 is loaded into the graphite hole 11 where the graphite backi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com