Dual-pressure expansion organic rankine cycle (ORC) mid-low-temperature waste heat recovery power generation system

A circulation system and low-temperature waste heat technology, applied in the field of energy and environment, to achieve the effects of reducing liquid delivery pumps, efficient cascade utilization, and simplifying the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

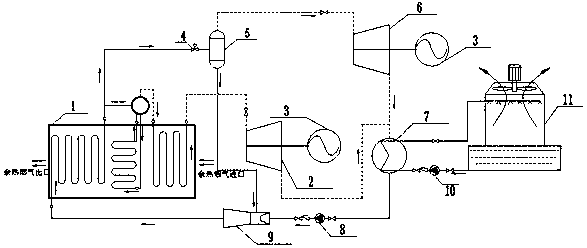

[0021] Such as figure 1 As shown, the dual-pressure expansion organic Rankine cycle recovery medium and low temperature waste heat power generation system includes a low-pressure organic Rankine cycle system, a high-pressure organic Rankine cycle system and connected pipelines and accessories; a low-pressure organic Rankine cycle system , The high-pressure organic Rankine cycle system includes ORC waste heat boiler 1, ORC waste heat boiler 1 is divided into preheating section, evaporation section and superheating section;

[0022] The low-pressure organic Rankine cycle system includes a preheating section of the ORC waste heat boiler 1, a pressure reducing valve 4, a flash evaporator 5, a screw expander 6, a generator 3, a condenser 7, a condensation pump 8, a jet compressor 9 and connections The composition of piping accessories; the high-pressure organic Rankine cycle system includes the evaporation section and superheat section of the ORC waste heat boiler 1, the centripetal tu...

Embodiment 2

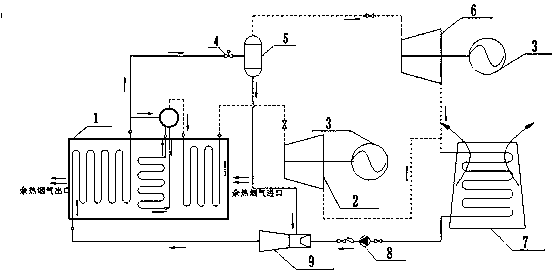

[0028] Such as figure 1 As shown, the dual-pressure expansion organic Rankine cycle recovery medium and low temperature waste heat power generation system includes a low-pressure organic Rankine cycle system, a high-pressure organic Rankine cycle system and connected pipelines and accessories; a low-pressure organic Rankine cycle system , The high-pressure organic Rankine cycle system includes ORC waste heat boiler 1, ORC waste heat boiler 1 is divided into preheating section, evaporation section and superheating section;

[0029] The low-pressure organic Rankine cycle system includes a preheating section of the ORC waste heat boiler 1, a pressure reducing valve 4, a flash evaporator 5, a screw expander 6, a generator 3, a condenser 7, a condensation pump 8, a jet compressor 9 and connections The composition of piping accessories; the high-pressure organic Rankine cycle system includes the evaporation section and superheat section of the ORC waste heat boiler 1, the centripetal tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com