Heat generating agent for converter steelmaking and production method thereof

A converter steelmaking and exothermic agent technology, applied in the field of metallurgy, can solve the problems of environmental pollution, high impurity content, and inability to apply high-quality steel, etc., and achieve the effect of excellent heating effect and increased specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

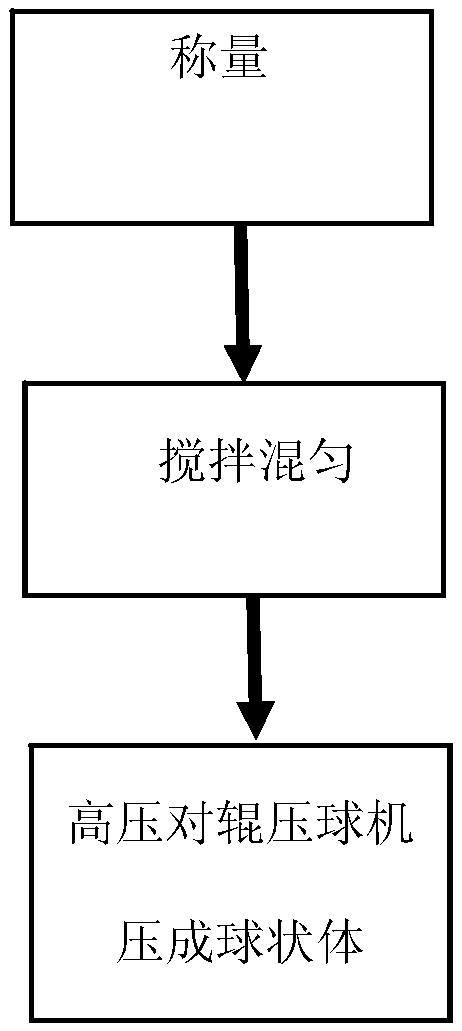

Method used

Image

Examples

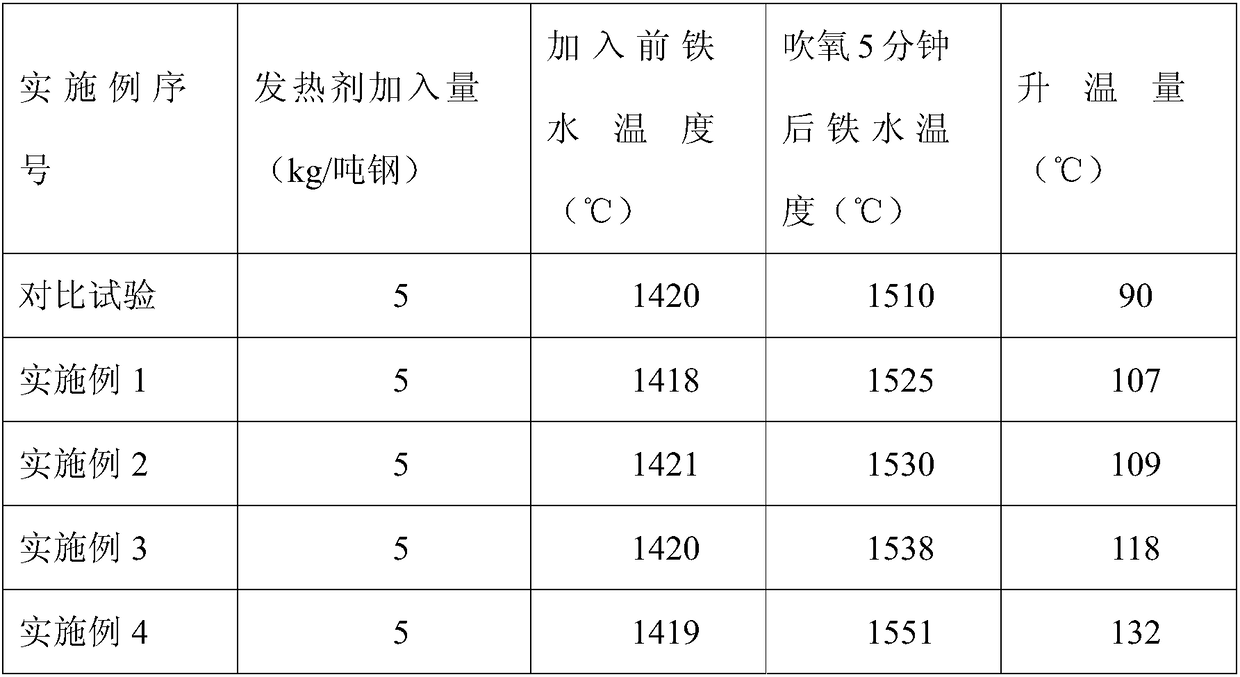

Embodiment 1

[0024] The heat generating agent for the converter steelmaking includes industrial silicon powder, AD powder, iron oxide raw material, binding agent, additive, and its percentage by weight is: industrial silicon powder 40%; AD powder 37%; iron oxide 20%; CMC binder 1%, silicon carbide 1%, metal aluminum powder 1%.

Embodiment 2

[0026] The heat generating agent for the converter steelmaking includes industrial silicon powder, AD powder, iron oxide raw material, binding agent, additive, and its percentage by weight is: industrial silicon powder 45%; AD powder 32%; iron oxide 20%; CMC binder 3%.

Embodiment 3

[0028] The heat generating agent for converter steelmaking includes industrial silicon powder, AD powder, iron oxide raw material, binder, and additives, and its weight percentage is: industrial silicon powder 50%; AD powder 27%; iron oxide 20%; CMC Binder 0.5%, water glass 0.2%, cement 0.2%, starch 0.1%, caustic soda 0.1%, 801 glue 0.1%, yellow dextrin 0.1%, silicon carbide 0.5%, metal aluminum powder 0.5%, ferrosilicon powder 0.5% %, graphite 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com