A waste incineration treatment system

A treatment system and waste incineration technology, applied in the field of waste incineration treatment system and waste incineration treatment, can solve problems such as flue gas emissions, and achieve the effects of reducing emissions, high purification efficiency, and no transmission mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

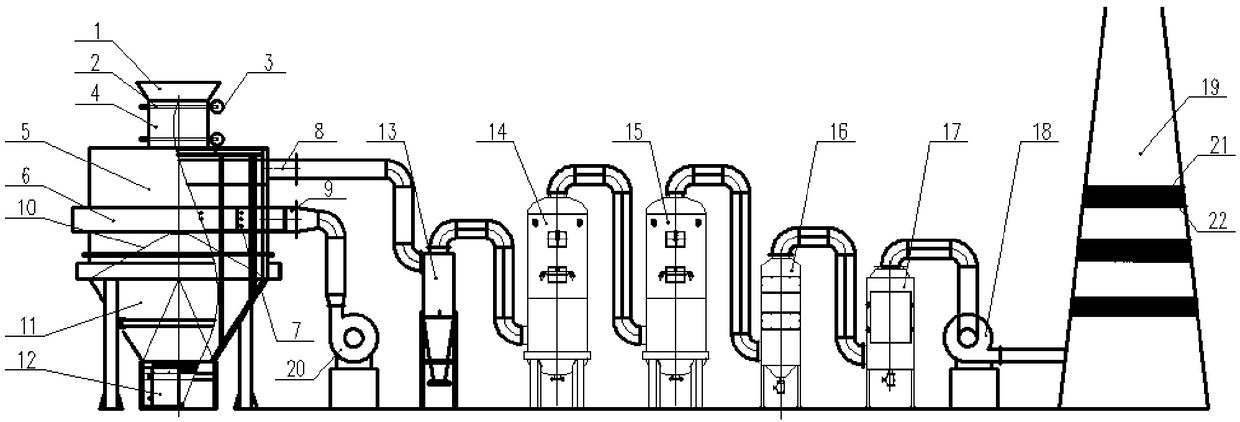

[0029] see figure 1 , the illustrated embodiment is a preferred embodiment of the present invention, specifically including incinerator 5, dust collector 13, first deacidification tower 14, second deacidification tower 15, mist removal tower 16, activated carbon Case 17, induced draft fan 18 and soil biological filter 19, and induced draft fan 18 is set on the smoke pipe, forms negative pressure suction to the flue gas inside the furnace cavity of incinerator.

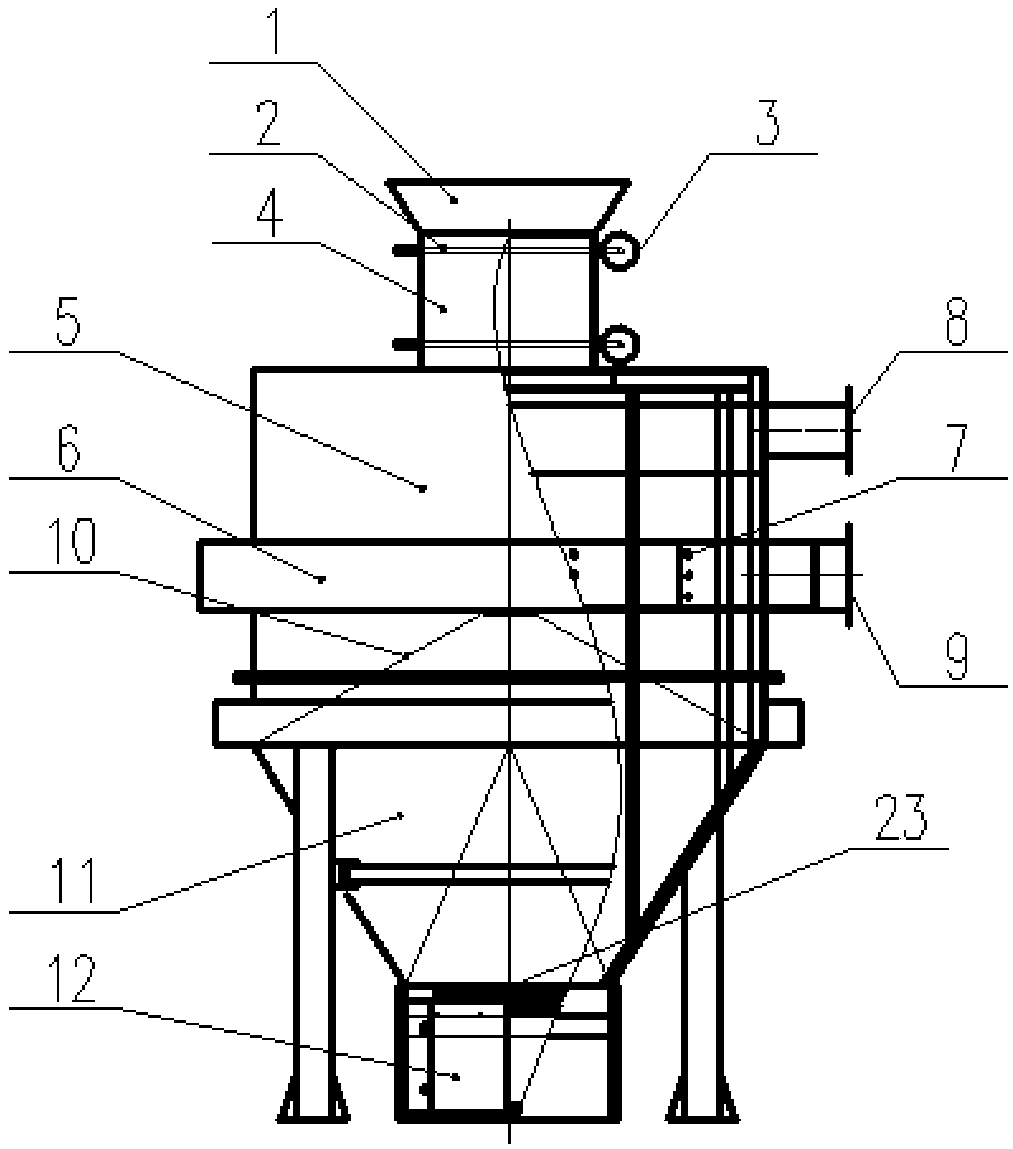

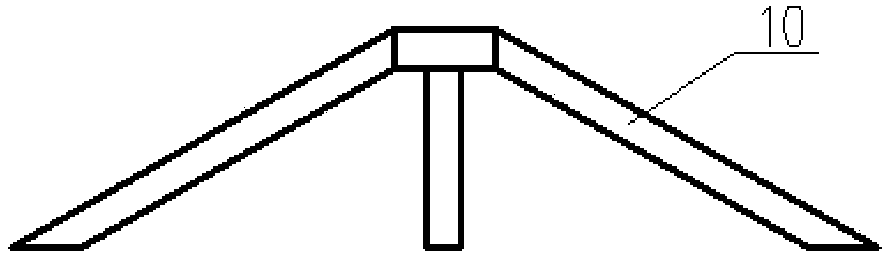

[0030] see in conjunction figure 2 , the incinerator 5 has a furnace cavity, the top of the furnace cavity is provided with a normally closed feed hopper 1, and a storage bin 4 is also provided between the feed hopper and the furnace cavity, and the feed hopper is arranged on the top of the storage bin; the bottom of the furnace cavity For the ash hopper 11, the bottom of the ash hopper is provided with a fixed fire grate 23 and ash-cleaning door 12, and a furnace arch 10 is set above the ash hopper 11, which is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com