Clean CO2/N2 foam fracturing fluid and preparation method thereof

A foam fracturing fluid and fracturing fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as impact on fracturing and production process, difficulty in recovery of fracturing fluid, damage to formation permeability, etc. Achieve strong carrying capacity, increase viscosity, and eliminate clay swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 - the selection of blowing agent

[0030] blank example

[0031] Add 100ml of liquid carbon dioxide into the autoclave, control the temperature at 2-5°C, and maintain the pressure at 4.5-5.5Mpa; inject 300ml of nitrogen into the autoclave, start stirring at a low speed, and observe the bubbles in the autoclave Condition.

Embodiment 2

[0036] Embodiment 2 - the selection of blowing agent consumption

[0037] Pour 100ml of the solution to be tested into a transparent container with a scale, stir at a high speed (8000r / min) for 60 seconds, and record the foam volume V when the stirring is stopped. o (ml) and the time t to separate 50ml of liquid from the foam 1 / 2 (called the half-life), with V o Indicates the foaming capacity, t 1 / 2 Indicates foam stability. The generated foam volume and half-life are related to the stirring speed. Therefore, when evaluating the performance of the foaming agent, the same rotational speed should be used for comparison. Obviously, V o The larger the value, the stronger the foaming ability; the half-life (t 1 / 2 The longer the value, the slower the liquid in the foam will lose and the better the stability of the foam, which is crucial to the drainage efficiency of deep wells.

[0038] Specifically, in this example, 100ml of liquid carbon dioxide, different contents of fluoro...

Embodiment 3

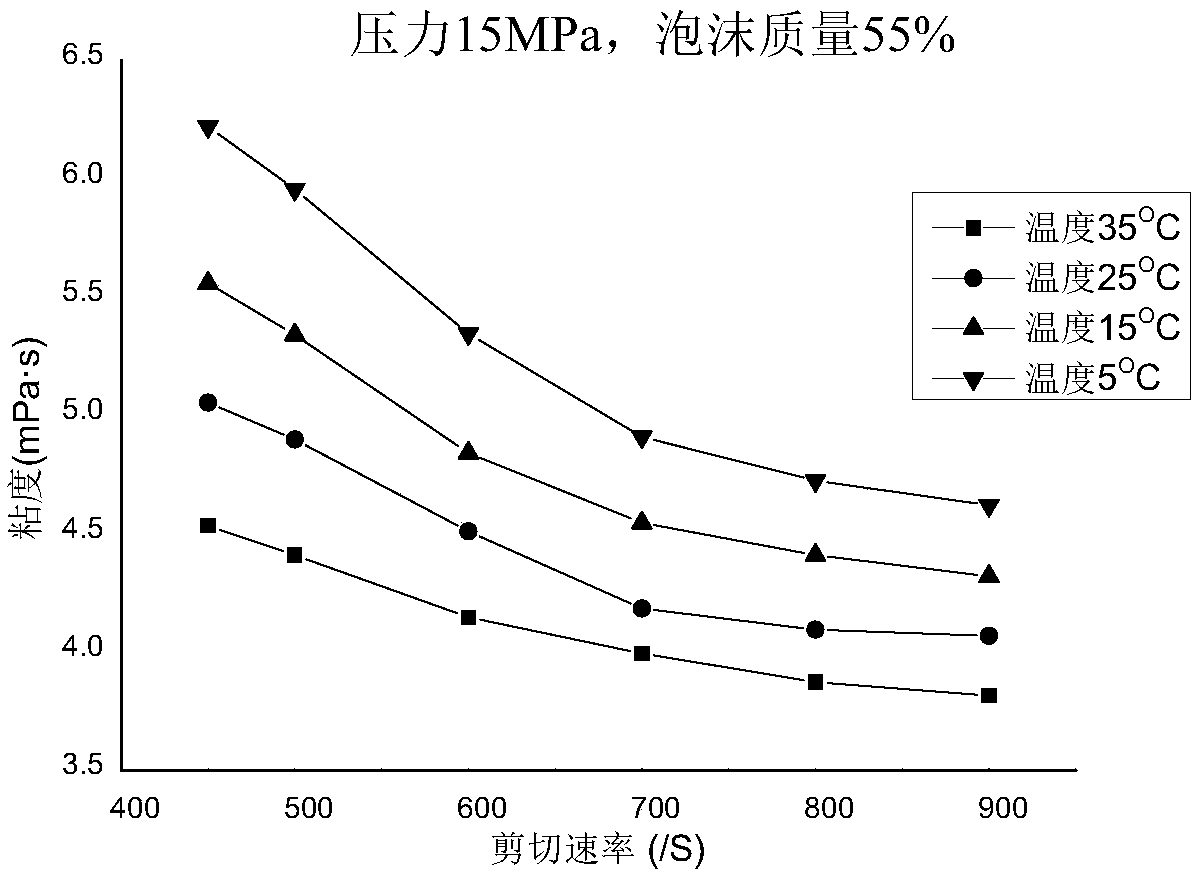

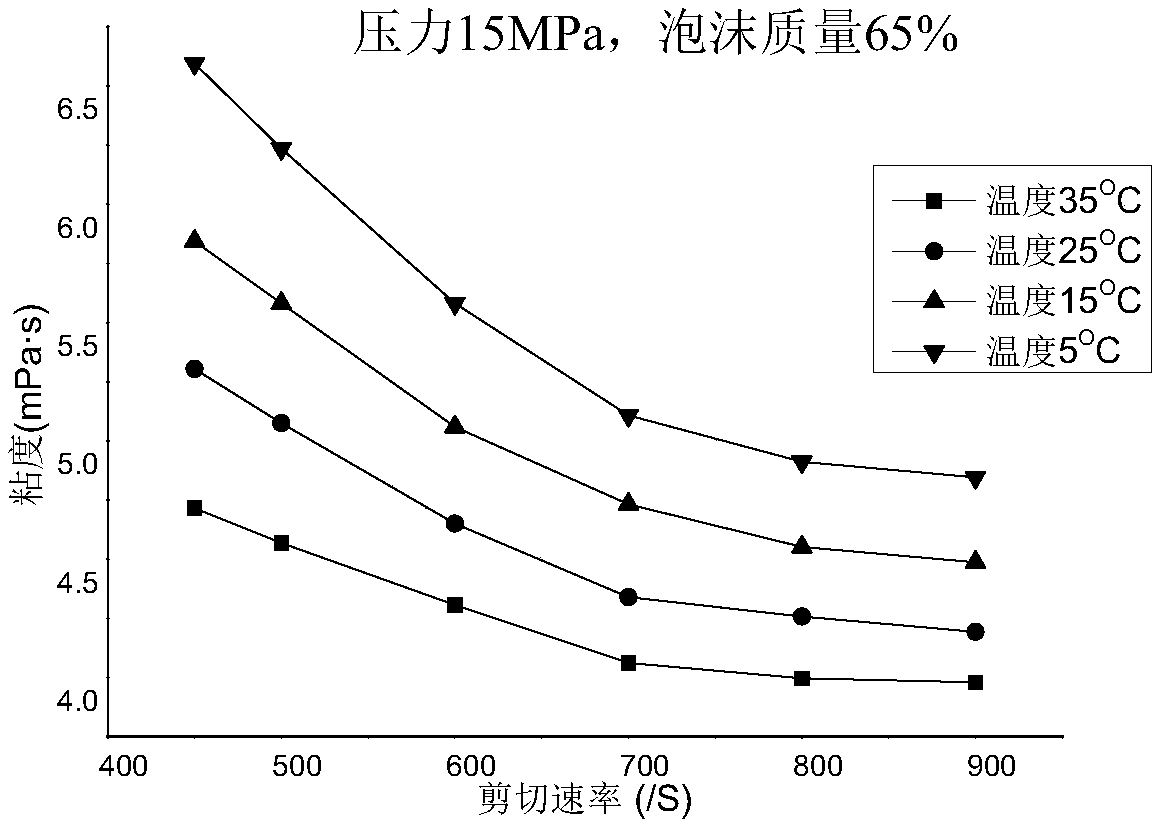

[0043] Embodiment 3——influencing factors of foam stability

[0044]Add 100ml of liquid carbon dioxide, 2% fluorohexanol polyoxyethylene ether and nitrogen into the reaction kettle to prepare the fracturing fluid. After the fracturing fluid bubbles, change the temperature, pressure, or nitrogen injection amount respectively, and then measure the half-life of the fracturing fluid.

[0045] (1) Influence of temperature

[0046] The control pressure was 3.4MPa, the nitrogen injection rate was 55%, and the influence of temperature on the half-life of fracturing fluid was investigated. The test temperatures were 2°C, 5°C, 10°C, 15°C, and 20°C. The test results are shown in Table 2.

[0047] Table 2

[0048]

[0049] (2) The influence of pressure

[0050] The temperature was controlled at 2°C and the nitrogen injection rate was 55%. The influence of pressure on the half-life of the fracturing fluid was investigated. The test pressure was between 3.4-15.5MPa. The test results ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com