Novel stir friction additive manufacturing machine

A technology of friction stir and additive manufacturing, which is applied in the field of engineering manufacturing, can solve the problem of high cost, achieve the effect of simplifying the additive manufacturing process, reducing costs, and avoiding the reduction of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

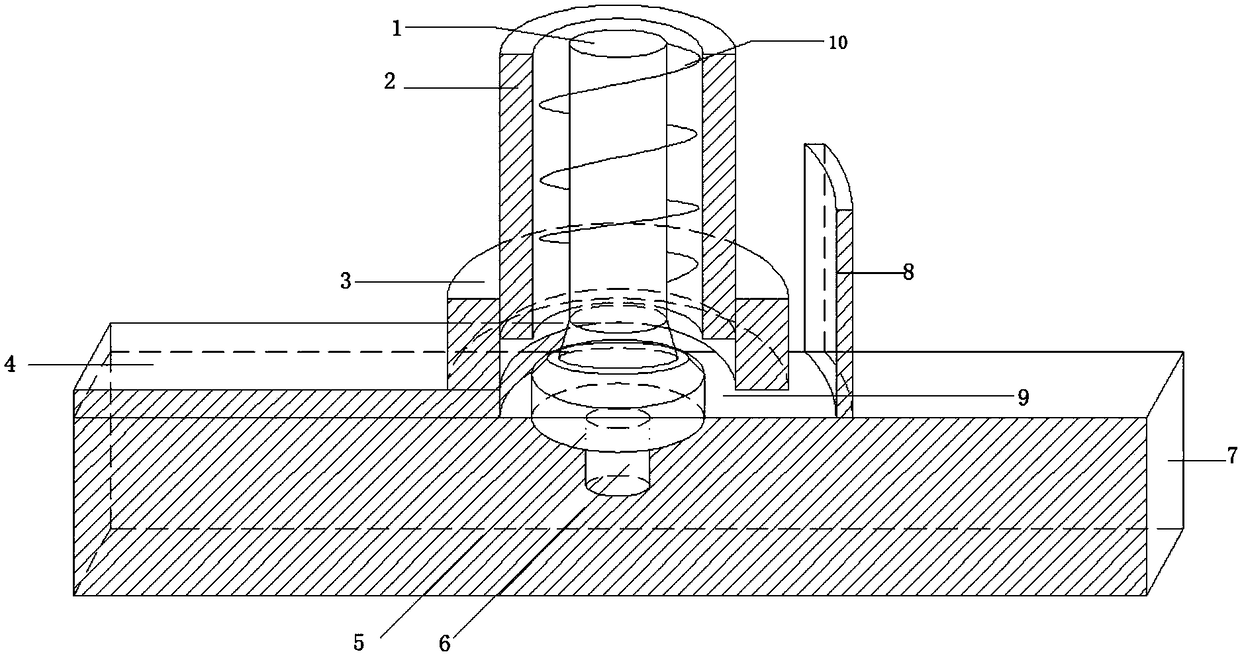

[0014] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0015] A new type of friction stir additive manufacturing machine, including a powder feeding system, a grinding system, a welding system, a powder outlet 9 and a baffle plate 8;

[0016] The powder feeding system includes a threaded bearing 1 and a feeding cylinder 10, the threaded bearing 1 is located inside the feeding cylinder 10, and the rotation of the bearing 1 generates a downward force to push the metal powder in the feeding cylinder 10 The material is pressed into the welding system;

[0017] The grinding system includes a sleeve 2 and a sleeve shoulder 3; the sleeve 2 is set on the outside of the feeding cylinder 10, the sleeve 2 is fixed on the sleeve shoulder 3 to form a whole, and the sleeve 2 It can rotate by itself and perform translational movement, and the rotation direction is consistent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com