An MEMS heating chip integrating multiple Pt temperature sensors and a manufacture method therefor

A temperature sensor and heating chip technology, applied in the field of electronic cigarettes, can solve the problems of ineffective monitoring, wrong calculation results, large temperature measurement errors, etc., and achieve the effects of avoiding inaccurate temperature measurement, uniform heating, and improving heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

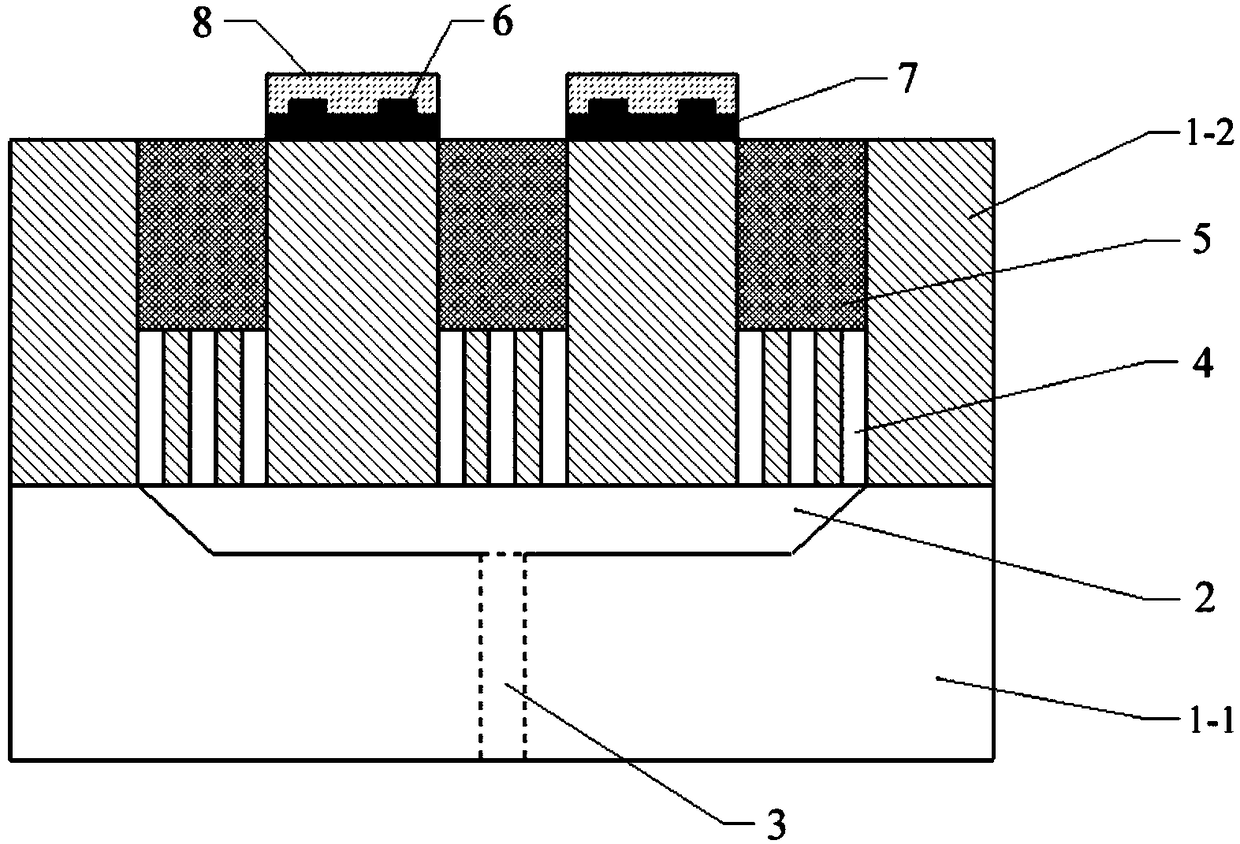

[0050] The first aspect of the present invention discloses a MEMS heating chip integrating multiple Pt thin film resistance temperature sensors, including:

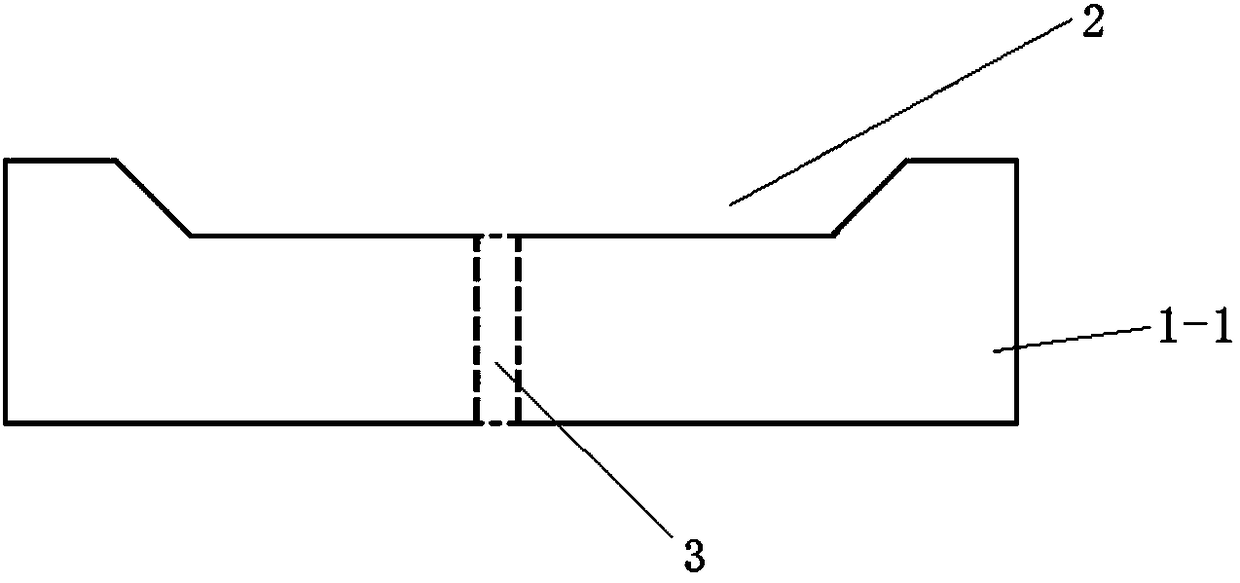

[0051] The first substrate (1-1) is sheet-shaped, and has a concave microcavity (2) on its front; microcavities (2) that penetrate the first substrate (1-1) are provided. through hole (3);

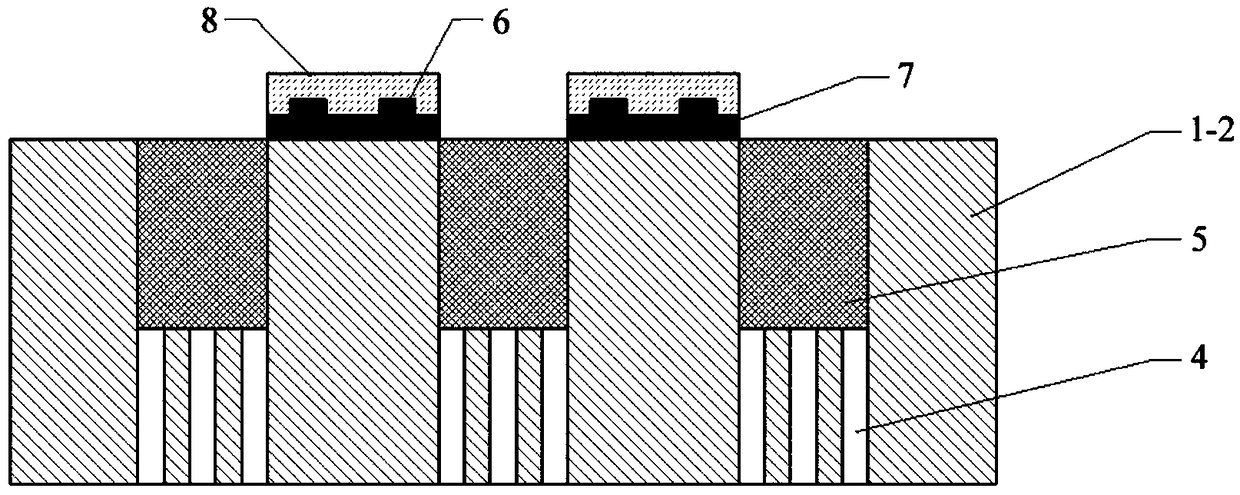

[0052] The second substrate (1-2), in sheet shape, has a microfluidic channel array (4) perpendicular to its backside on its back side, and a porous structure (5) perpendicular to its front side is provided in the front central area, and the microfluidic The channel array (4) communicates with the porous structure (5); there are multiple Pt thin film resistance temperature sensors (6) on its front surface;

[0053] The front side of the first substrate (1-1) is glued together with the back side of the second substrate (1-2).

[0054] The depth of the microcavity (2) is 3 mm; the diameter of the micro through hole (3) is 750 microns....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com