Method for improving fault range finding precision of CRH (China Railway High-speed) maintenance and management traction substation

A traction substation, fault location technology, applied in the fault location, measurement power, measurement device and other directions, can solve the problem of not considering the AT lightning resistance circle factor, large ranging error, large fault ranging error, etc. The effect of improving fault location accuracy, improving operation accuracy and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

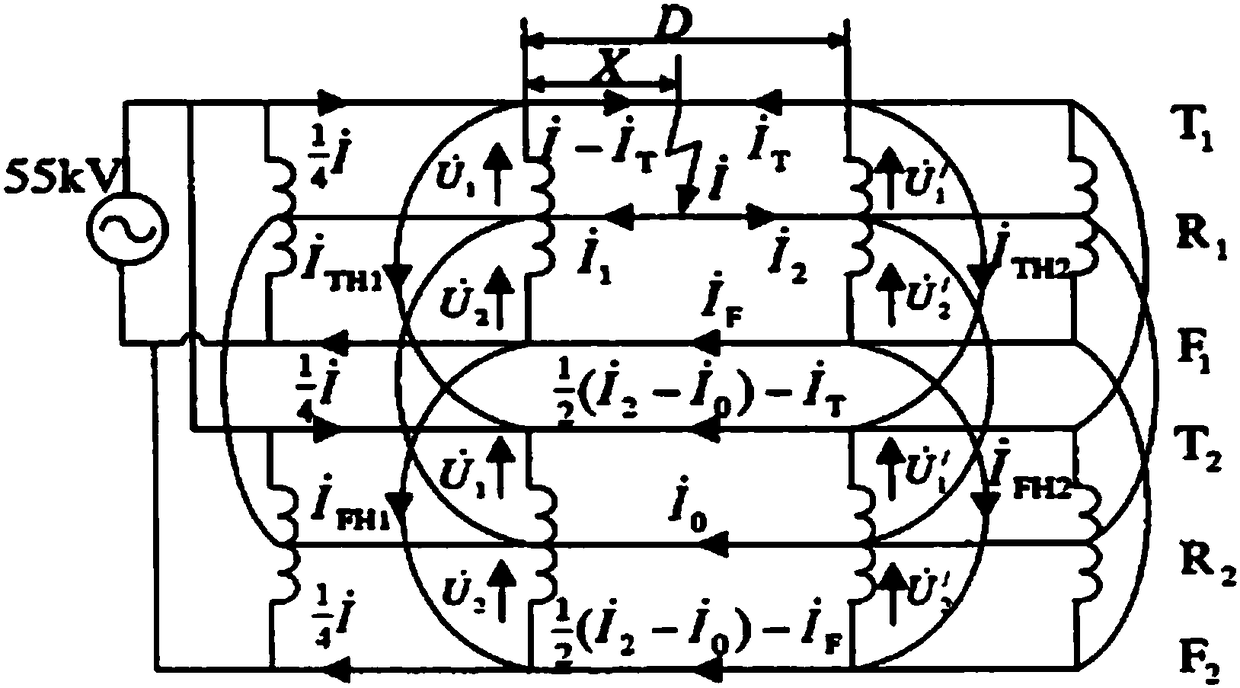

[0079] Due to Guiguang, the successful bidder for the measurement device system equipment originally used the AT neutral point suction current ratio distance measurement principle, which was affected by the number of stock lines in the station, earth leakage, AT leakage reactance, current mutual polarity and short-circuit transition impedance at the fault point. After the power supply equipment of Guizhou-Guangzhou high-speed railway tripped, the error between the fault mileage standard provided by the fault detection device and the fault point actually found was very large.

[0080] In order to improve the fault measurement accuracy of the existing fault distance measuring device, after a tripping fault occurs, the fault point can be quickly found and dealt with according to the fault distance measurement mark, so as to ensure the safety of the high-speed rail power supply equipment. It is the research direction to add the revised calculation formula of the traction anti-light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com