Transmitter diaphragm anti-high pressure shock and anti-freezing device

An anti-freezing device and anti-shock technology, applied in measuring devices, measuring fluid pressure, instruments, etc., can solve problems such as affecting the safe operation of the process, measuring and displaying dead points, and measuring diaphragm damage, achieving ingenious and compact structure design and ingenious design. , to ensure the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

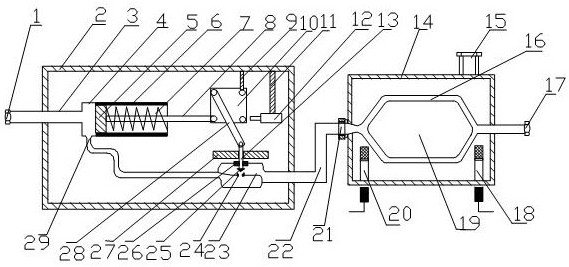

[0020] Embodiment 1: see figure 1 , the transmitter diaphragm anti-high pressure shock and antifreeze device, the device includes an antifreeze assembly and an anti-shock assembly, the antifreeze assembly and the anti-shock assembly are connected through a communication pipe and a joint, and the anti-shock assembly includes an anti-shock assembly The device casing, the pressure induction tube arranged inside the casing, the pressure induction sleeve 4, the thrust conversion mechanism, the high and low pressure switching mechanism and the position detection mechanism, the pressure induction tube is arranged in the pressure induction sleeve, and the upper part of the thrust conversion mechanism is connected The position detection mechanism is connected to the high and low pressure switching mechanism below, and the thrust conversion mechanism includes a horizontal push rod 8, a square plate 10, a movable connecting rod 28 and a vertical push rod 13, and the movable connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com