Composite tube plate for heat exchanger and heat exchanger containing same

A heat exchanger and composite tube technology, which is applied in the field of composite tube sheets for heat exchangers and heat exchangers containing the composite tube sheets, can solve the problems of limited use pressure and use temperature of polytetrafluoroethylene tube sheets, easy deformation, mechanical Limited strength and other issues, to achieve the effect of promoting application, enhancing mechanical strength, and ensuring safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

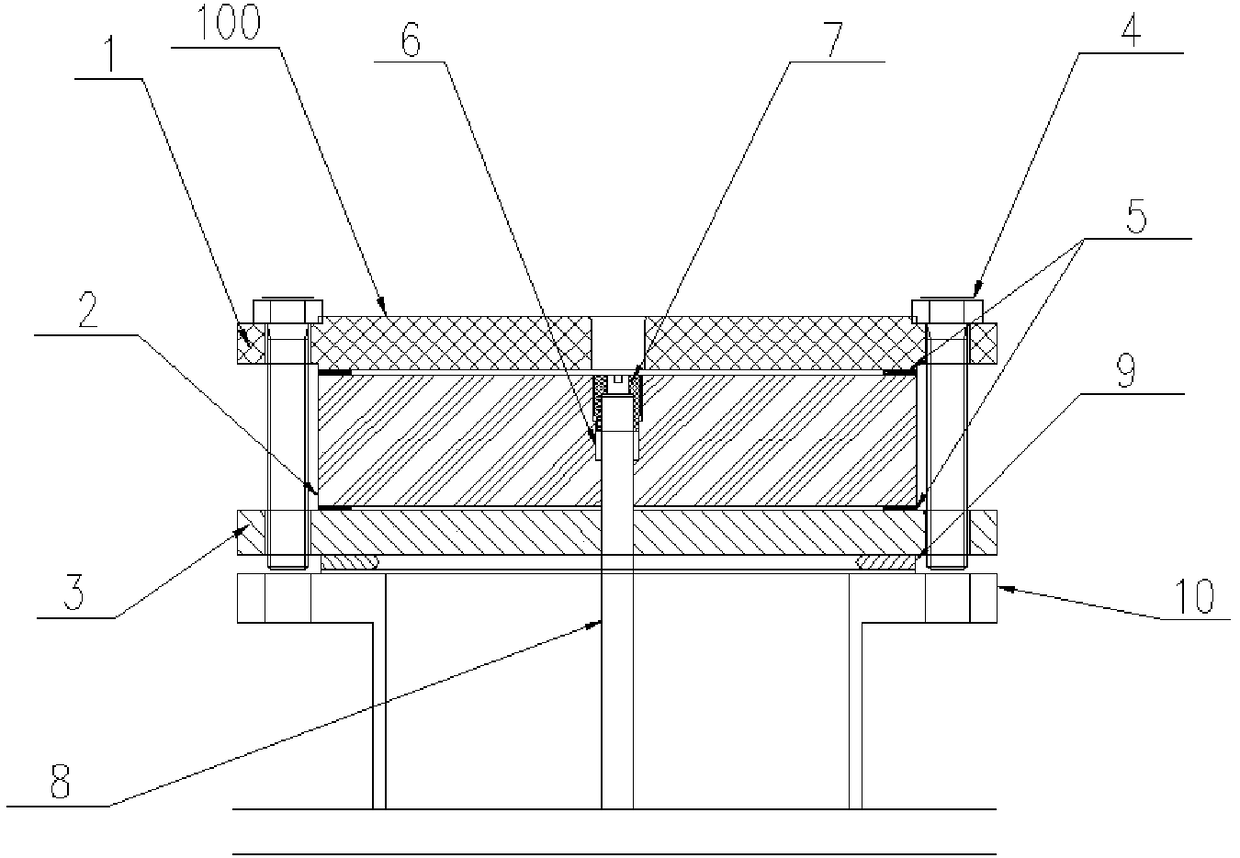

[0064] like figure 1 As shown, the embodiment of the present invention provides a composite tube sheet for a heat exchanger, which sequentially includes a metal orifice plate 1, a polytetrafluoroethylene tube sheet 2 and a metal reinforcement plate 3; a metal orifice plate 1, a polytetrafluoroethylene tube sheet 2 and The metal reinforcing plate 3 is fixed into an integral structure through the connecting piece 4; between the metal orifice plate 1 and the polytetrafluoroethylene tube plate 2, and between the polytetrafluoroethylene tube plate 2 and the metal reinforcing plate 3 are provided with a seal 5;

[0065] Wherein, the outer surface of the metal orifice plate 1 is sprayed with the corrosion-resistant material 100 , while the outer surface of the metal reinforced plate 3 is not sprayed with the corrosion-resistant material 100 .

[0066] Specifically, the metal reinforcement plate 3 is arranged on the non-process side of the polytetrafluoroethylene tube sheet 2, and the...

Embodiment 2

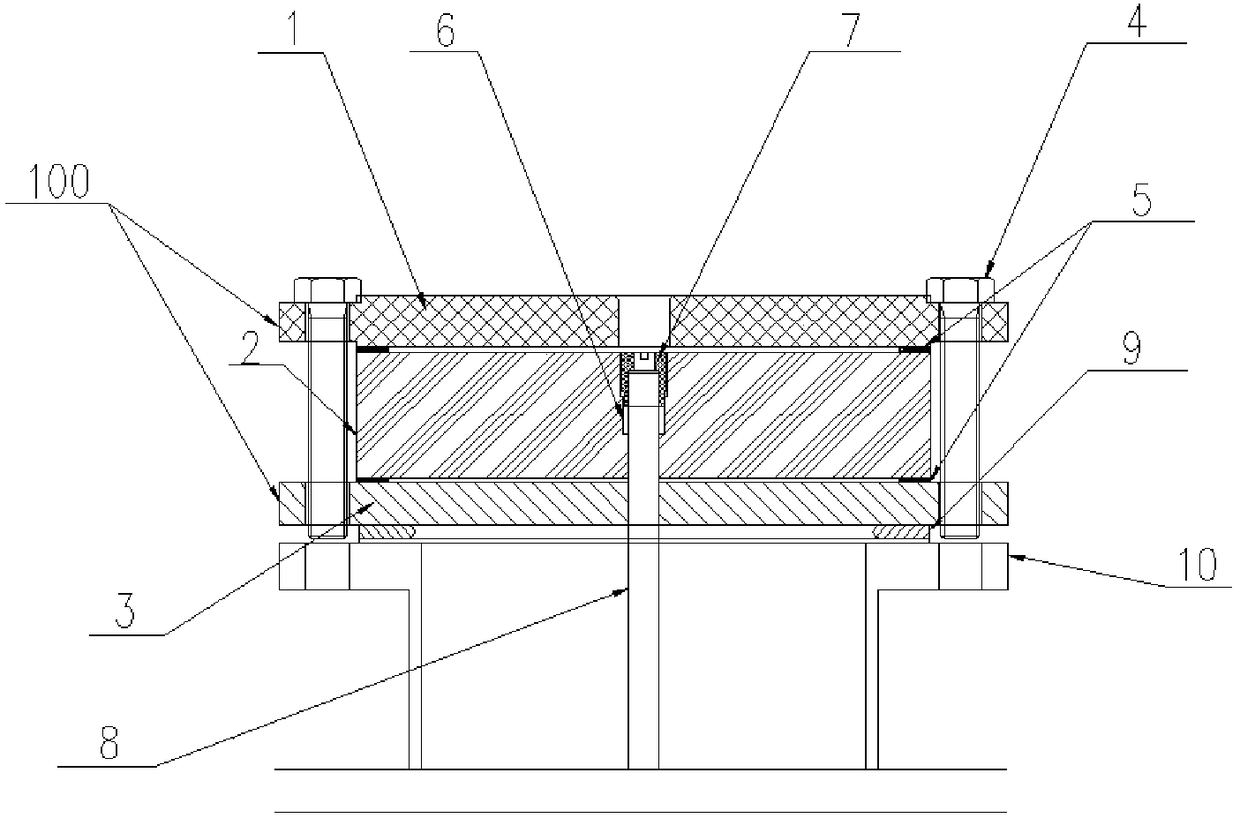

[0084] The composite tube sheet for the heat exchanger in the second embodiment is an improvement on the basis of the first embodiment, and the technical features disclosed in the first embodiment are also applicable to this embodiment, and the technical features disclosed in the first embodiment will not be described repeatedly.

[0085] like figure 2As shown, this embodiment provides a composite tube sheet for a heat exchanger, which sequentially includes a metal orifice plate 1, a polytetrafluoroethylene tube sheet 2 and a metal reinforcement plate 3; a metal orifice plate 1, a polytetrafluoroethylene tube sheet 2 and a metal The reinforcing plate 3 is fixed into an integral structure through the connecting piece 4; a sealing member 5 is provided between the metal orifice plate 1 and the PTFE tube plate 2, and between the PTFE tube plate 2 and the metal reinforcing plate 3;

[0086] Wherein, the outer surfaces of the metal orifice plate 1 and the metal reinforcing plate 3 ...

Embodiment 3

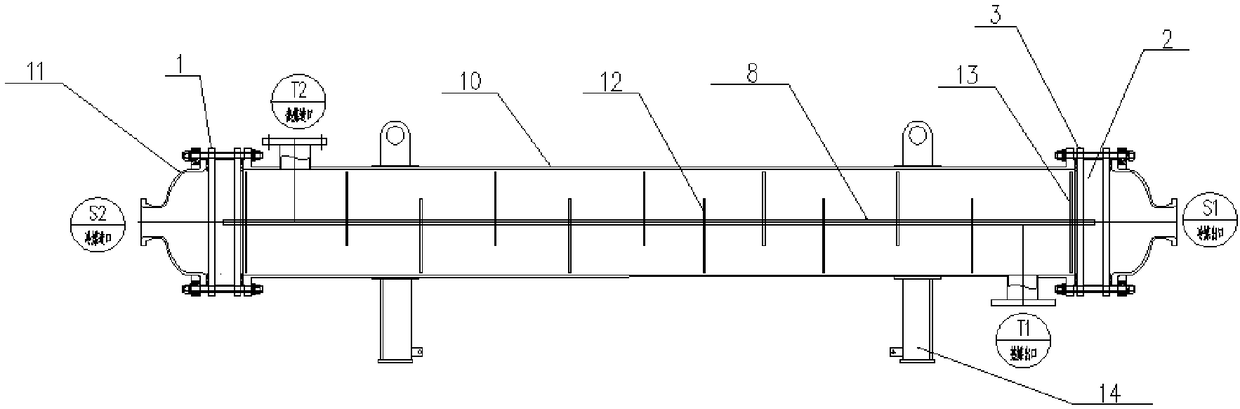

[0089] Embodiment 3 provides a heat exchanger, which includes the composite tube sheet for heat exchangers in Embodiment 1. The technical content disclosed in Embodiment 1 will not be described repeatedly, and the content disclosed in Embodiment 1 also belongs to this document. The content disclosed by the embodiment.

[0090] like image 3 As shown, this embodiment provides a heat exchanger, including a shell 10, both ends of the shell 10 are provided with a head 11, between the shell 10 and the head 11 is provided with the heat exchange device described in the first embodiment. Composite tube sheets for appliances.

[0091] In the optional solution of this embodiment, a plurality of heat exchange tubes 8 are arranged inside the shell 10, and the axes of the plurality of heat exchange tubes 8 are parallel to each other; the heat exchange tubes 8 include silicon carbide heat exchange tubes, silicon nitride heat exchange tubes One or more of tubes and glass heat exchange tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com