Mini type engine combustion chamber evaporation pipe structure with whirlcone

A cyclone and evaporating tube technology, applied in the field of new evaporating tube design, can solve the problems of unstable combustion and unsatisfactory mixing degree, and achieve the effects of simple structure, easy processing and uniform fuel oil distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described now in conjunction with accompanying drawing:

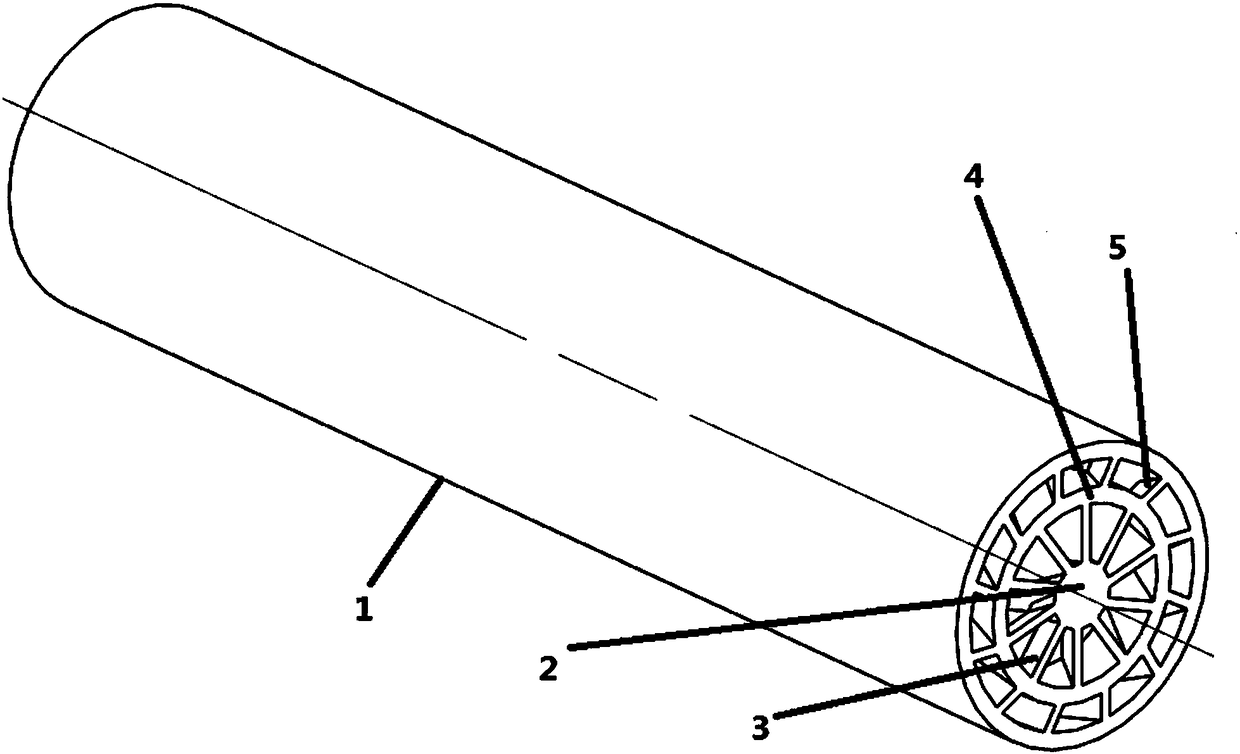

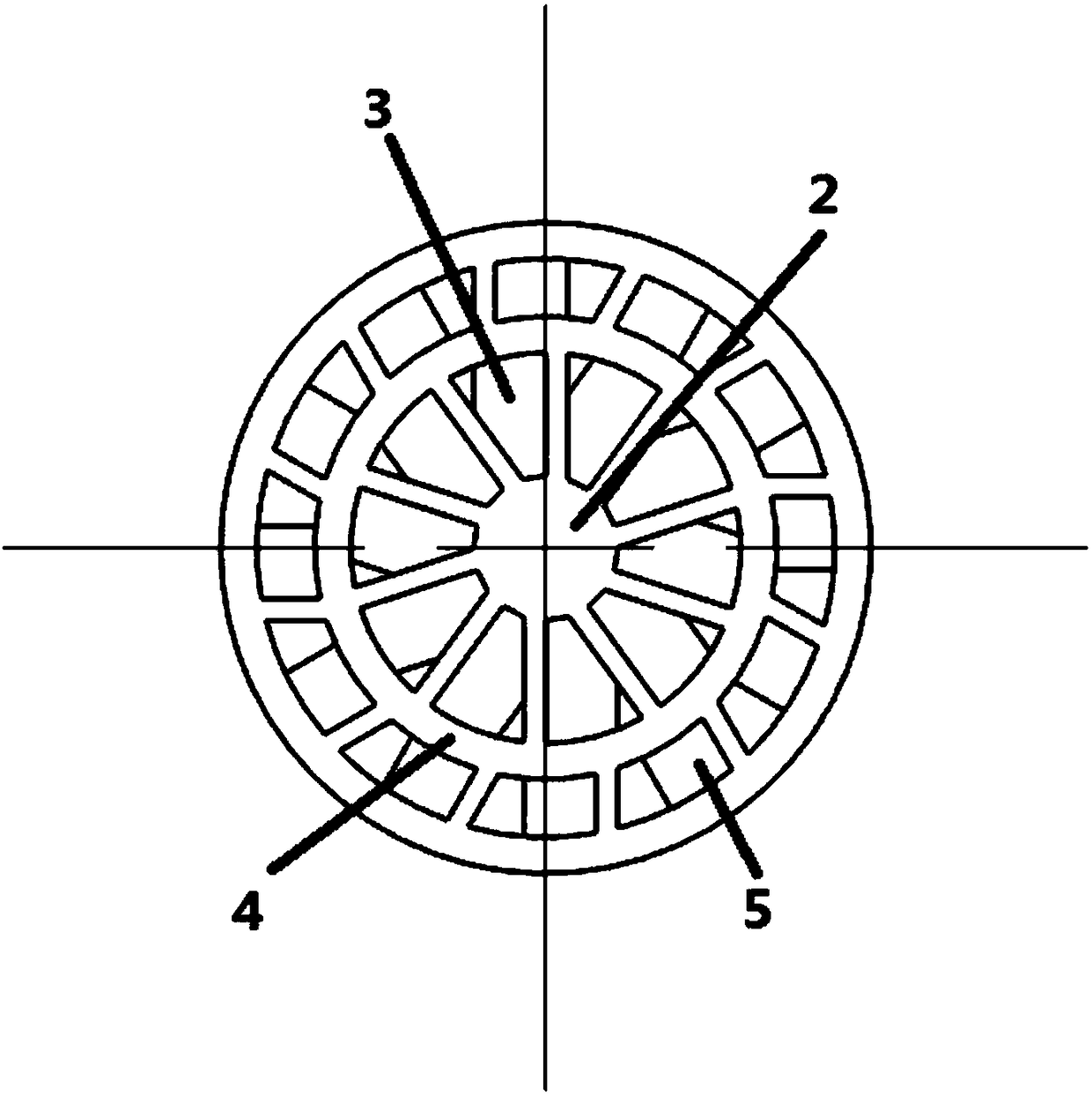

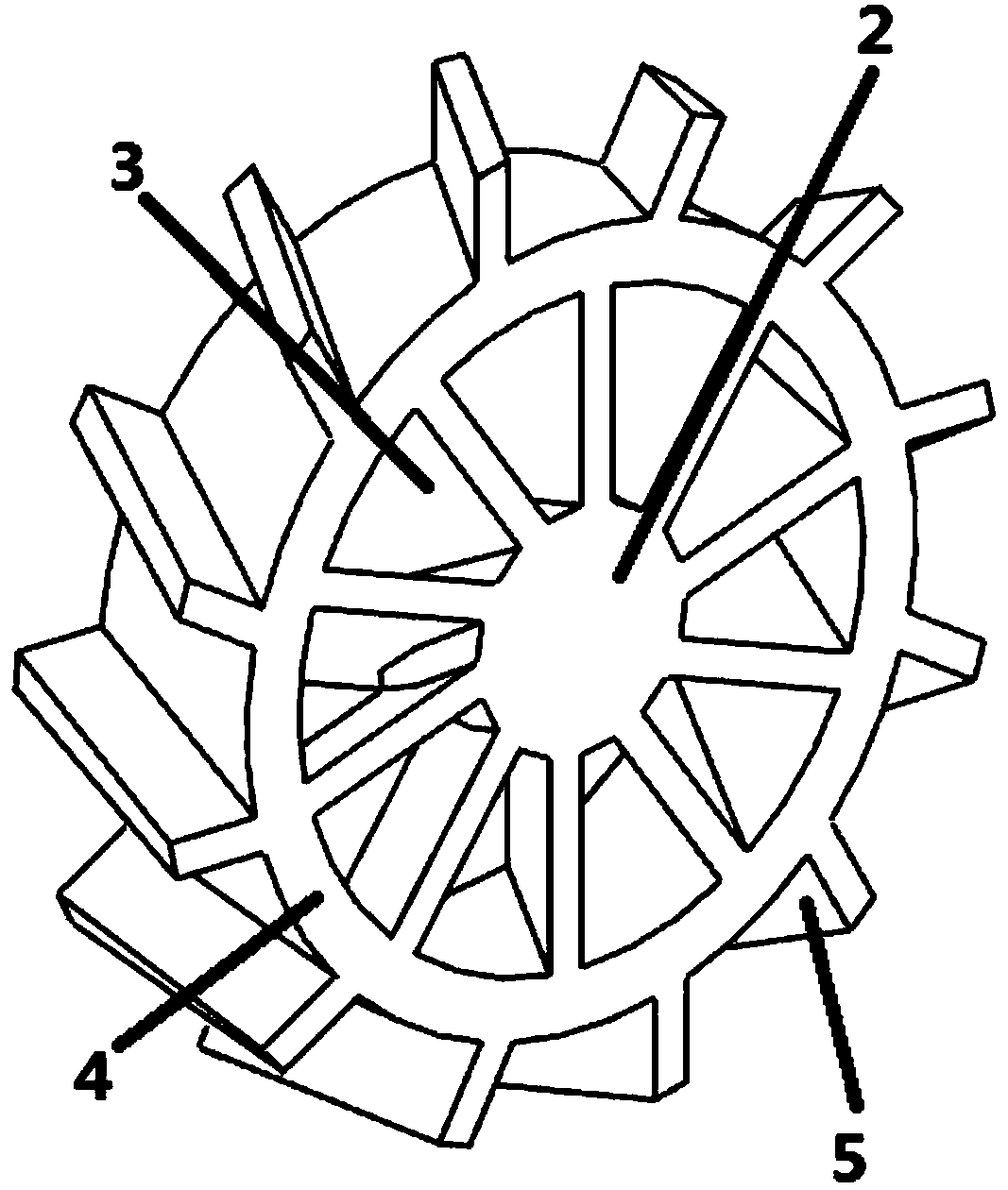

[0021] combine figure 1 , figure 2 and image 3 , the present invention provides an evaporation tube structure capable of enhancing the degree of oil-gas mixing in the micro-combustion chamber and stabilizing the end outlet of the flame with a double-stage cyclone. figure 1 is the overall schematic diagram of the evaporation tube, figure 2 It is the front view of the outlet direction of the evaporating tube, image 3 It is a schematic diagram of the structure of the two-stage cyclone, and the distribution of the blades of the two-stage cyclone can be clearly seen, and the rotation direction of the blades of the first and second-stage cyclone is opposite.

[0022] according to figure 1 As shown, the mixed flow of fuel and air enters the evaporator tube (1) from the inlet of the evaporator tube. In the evaporator tube (1), the fuel is heated and evaporated. After passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com