Method for synthesizing tin selenide powder at room temperature

A room temperature synthesis, tin selenide technology, applied in the direction of metal selenide/telluride, binary selenium/telluride compounds, etc., can solve the problems of unhealthy operators, difficult to dissolve, environmental pollution, etc. Low heating and preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 2.4g of tartaric acid and dissolve it in 20mL of distilled water, stir until dissolved to obtain a clear and transparent solution, then add 2mmol of tin dichloride, stir until the solution becomes clear and transparent, and obtain solution A.

[0028] Add 1mmol of selenium dioxide, 0.8g of sodium hydroxide and 2mmol of sodium borohydride into 15mL of distilled water in sequence, and stir evenly to obtain a transparent solution B.

[0029] Slowly add solution A to transparent solution B, stir at room temperature for 15 minutes, collect the sample by centrifugation, then put it in an oven for 3 hours at 60°C, and then cool it down to room temperature naturally to obtain black tin selenide powder.

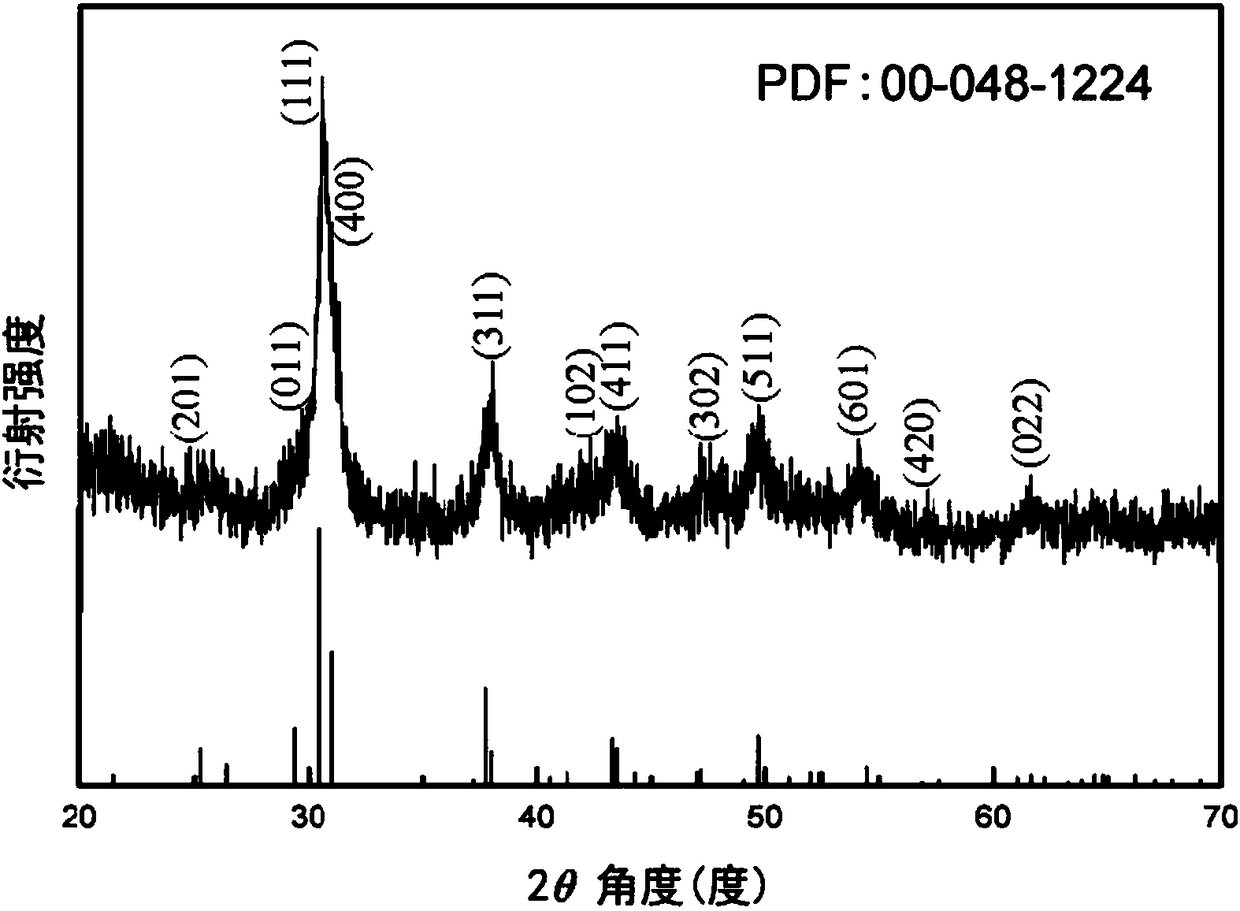

[0030] figure 1 is the XRD spectrum of the product, no impurity peaks appear, indicating that the product is pure tin selenide.

[0031] figure 2 is the SEM photo of the product. From figure 2 It can be seen that the SnSe is agglomerated in granular form.

Embodiment 2

[0033] Weigh 2.34g of EDTA and dissolve it in 20mL of distilled water, stir until dissolved, then add 1mmol of tin dichloride to prepare solution A.

[0034] Add 1mmol of selenium dioxide, 0.8g of sodium hydroxide and 2mmol of sodium borohydride into 15mL of distilled water in sequence, and stir evenly to obtain a transparent solution B.

[0035] Slowly add solution A to transparent solution B, stir at room temperature for 15 minutes, collect the sample by centrifugation, then put it in an oven for 3 hours at 65°C, and then cool it down to room temperature naturally to obtain black tin selenide powder.

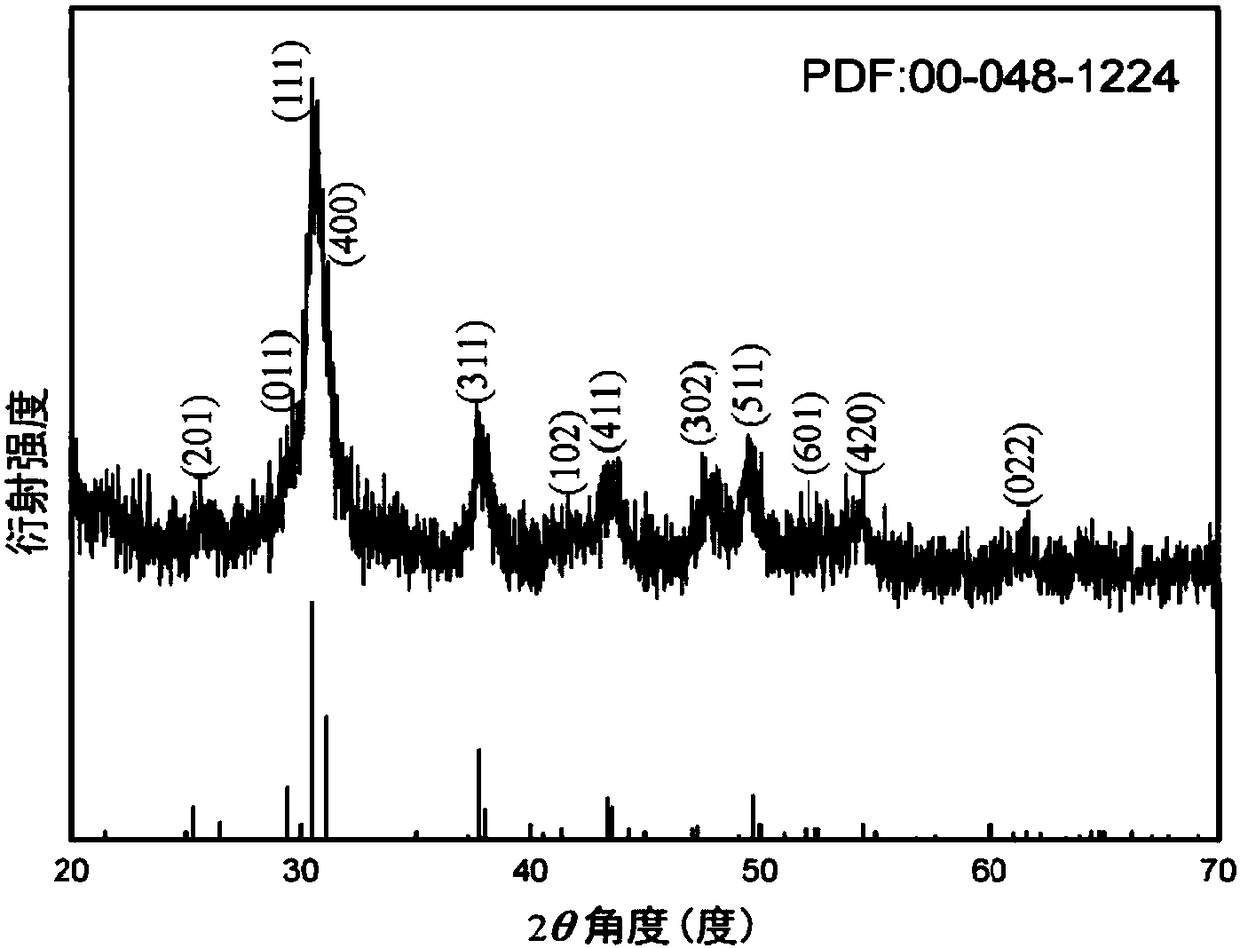

[0036] image 3is the XRD spectrum of the product, no impurity peaks appear, indicating that the product is pure tin selenide.

[0037] Figure 4 is the SEM photo of the product. From Figure 4 It can be seen that lamellar SnSe is formed.

Embodiment 3

[0039] Weigh 2.31 g of citric acid and dissolve it in 20 mL of distilled water, stir until dissolved to obtain a clear and transparent solution, then add 2 mmol of tin dichloride, stir until the solution becomes clear and transparent, and obtain solution A.

[0040] Add 1mmol of selenium dioxide, 0.8g of sodium hydroxide and 2mmol of sodium borohydride into 15mL of distilled water in sequence, and stir evenly to obtain a transparent solution B.

[0041] Slowly add solution A to transparent solution B, stir at room temperature for 15 minutes, collect the sample by centrifugation, then put it in an oven for 2 hours at 70°C, and then cool it down to room temperature naturally to obtain black tin selenide powder.

[0042] Figure 5 is the XRD spectrum of the product, no impurity peaks appear, indicating that the product is pure tin selenide.

[0043] Figure 6 is the SEM photo of the product. From Figure 6 It can be seen that SnSe is granular.

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com