Annular storing device based on circular arc guide rail

A circular-arc guide rail and ring-shaped technology, which is applied in the field of automation control, can solve the problems of sudden change in the movement speed of the silo, easy wear of the movable wheel, and low operating speed, and achieve the effects of small running resistance, improved stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

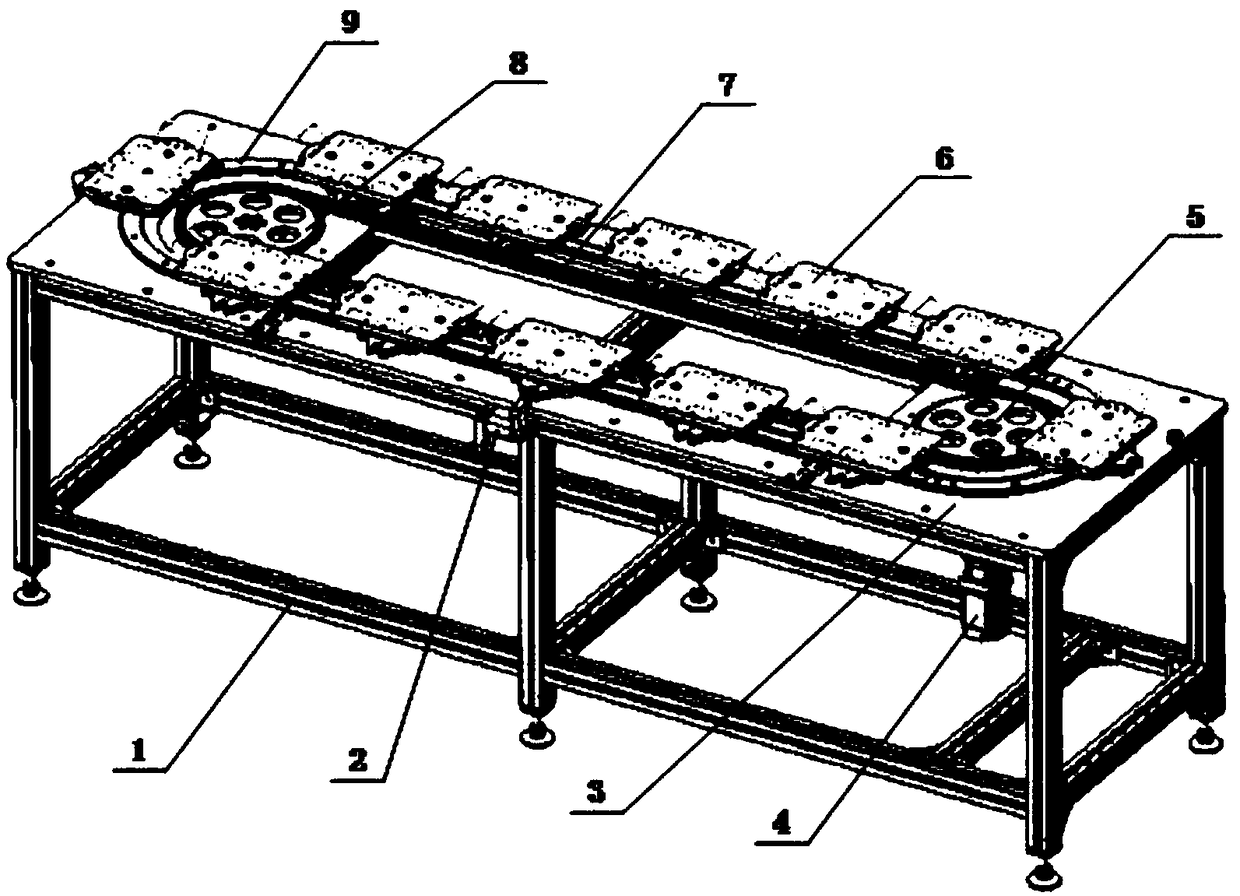

[0028] The invention provides a circular storage device based on a circular arc guide rail, such as figure 1 As shown, including a frame 1, a positioning mechanism 2 is fixed on the pick-and-place material point of the frame 1, a horizontally arranged guide rail support plate 3 is fixed above the frame 1, and an annular guide rail structure 9 is arranged on the guide rail support plate 3. The two ends of the ring guide rail structure 9 are the same circular arc roller guide rails arranged symmetrically, and the arc roller guide rails are connected by two parallel linear roller guide rails. The ring guide rail structure 9 is uniformly provided with several slide rails matching the roller guide rails. seat 6; the guide rail support plate 3 is also provided with a sprocket chain drive, the sprocket chain drive is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com