Self-controlled vertical thread adjusting device

A thread adjuster, vertical technology, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problems of the thread adjuster not moving in place, affecting weaving, easily being squeezed by oil stains, cotton wool and dander, etc. Achieve the effect of improving stability, ensuring stability and improving textile production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

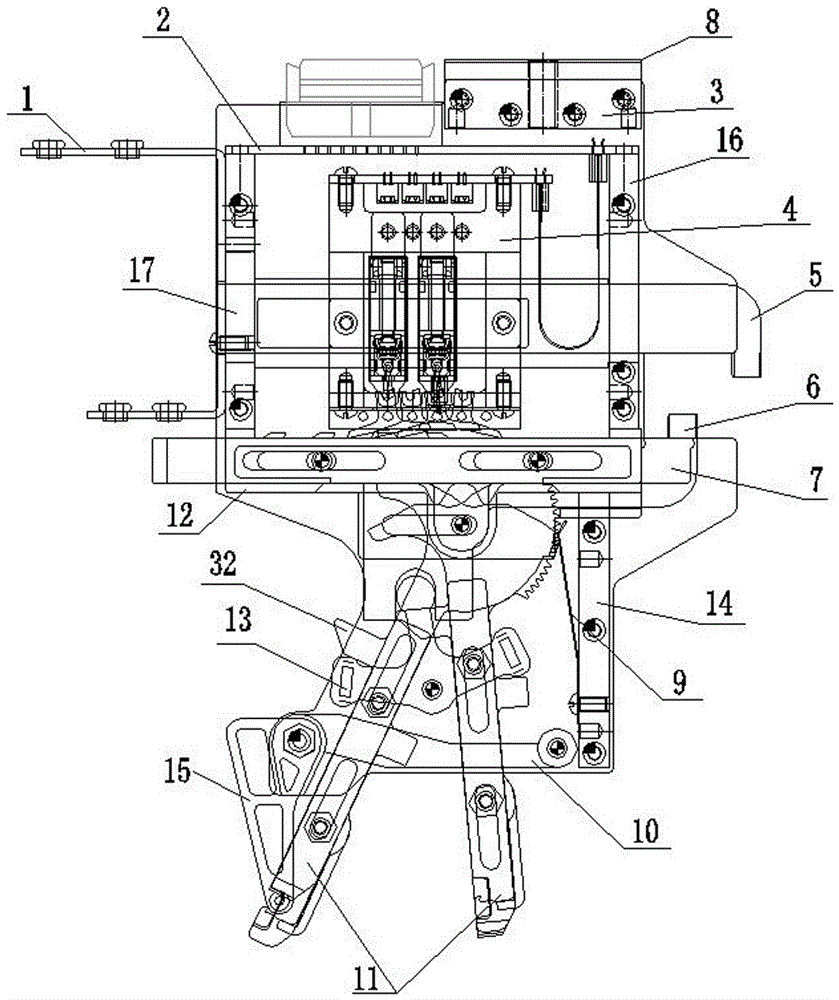

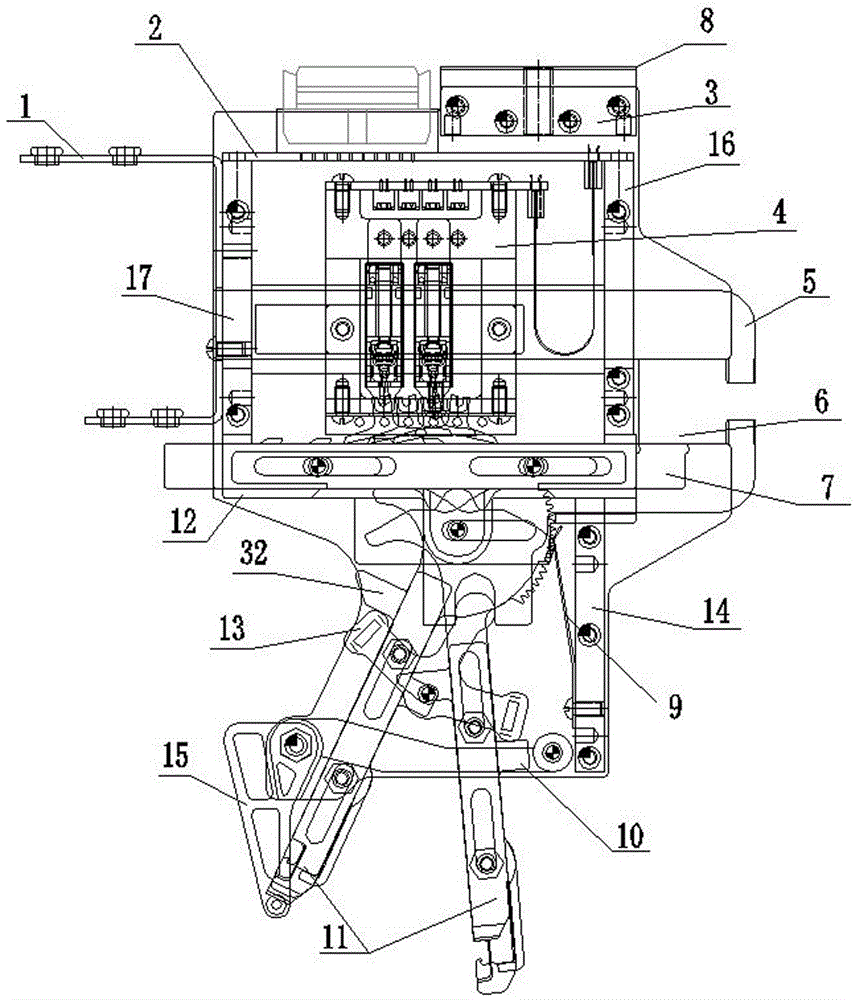

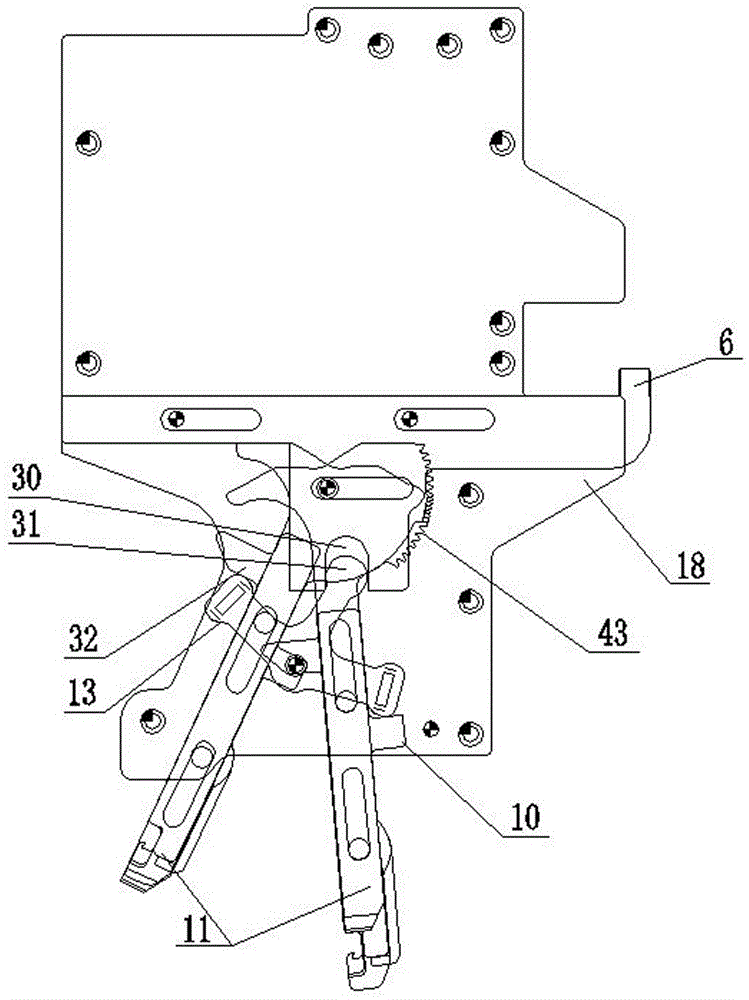

[0037] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19, comprising a thread adjuster main body 8, a controller 4, a yarn clamping and cutting device 11, a yarn threading device, a push-pull rod, and a linkage rod 7, and the yarn threading device includes a yarn threading board 1, a yarn feeding finger 15, a yarn threading board 1 and a feeding Magnetic eyes are attached to the yarn fingers 15, which are used to guide the yarn and reduce the resistance of the yarn during weaving. The push-pull rod is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com