A multifunctional mechanical cold machining hole cutting machine clamping tool

A technology of multi-functional machinery and cutting machine, applied in the direction of boring bars, etc., can solve the problems of high cost and low processing efficiency, and achieve the effect of short tool change time, easy tool change and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

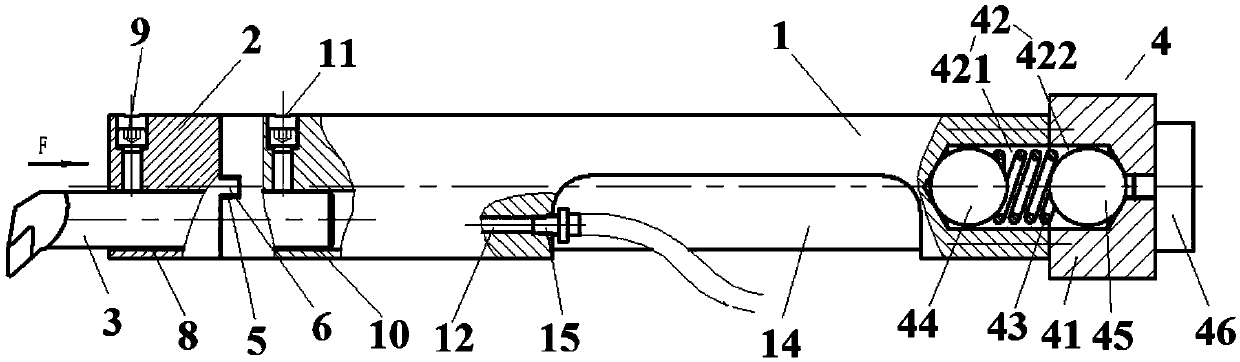

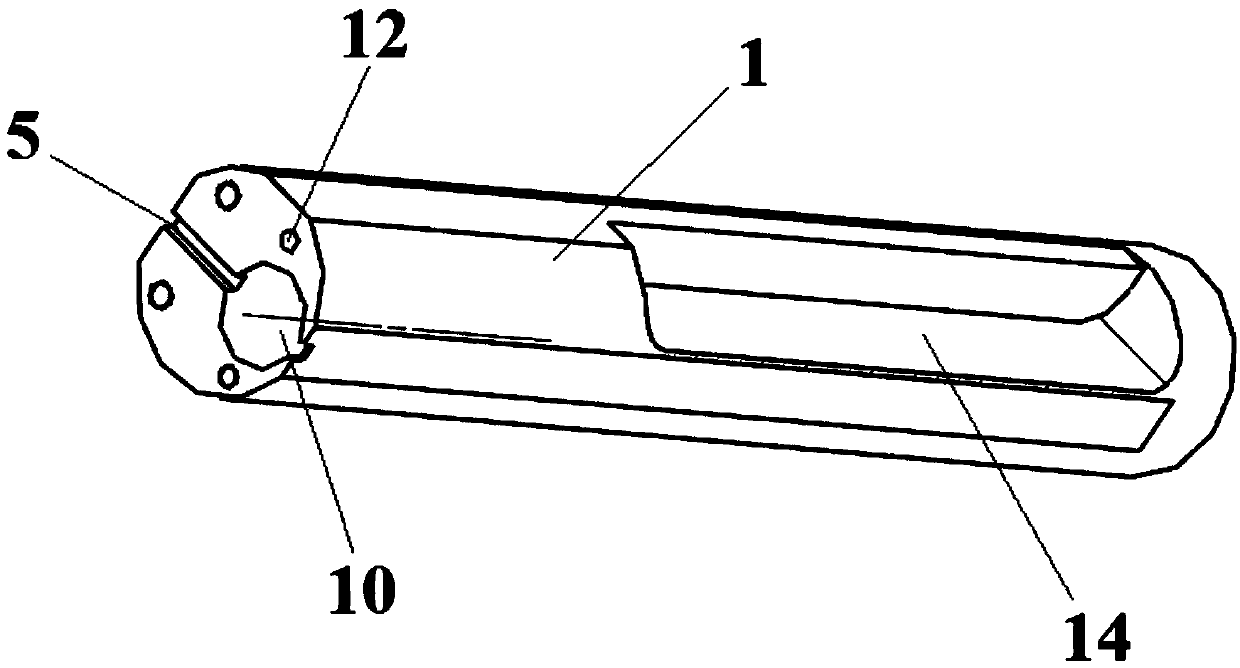

[0027] The present embodiment provides a kind of multifunctional mechanical cold working hole cutting machine holder tool, as Figure 1 to Figure 3 As shown, it includes a knife bar 1, the head end of the knife bar 1 is detachably equipped with a knife body 2, and a knife head 3 is detachably installed on the knife body 2; the tail end of the knife bar 1 is equipped with a Heavy shock absorbing mechanism4.

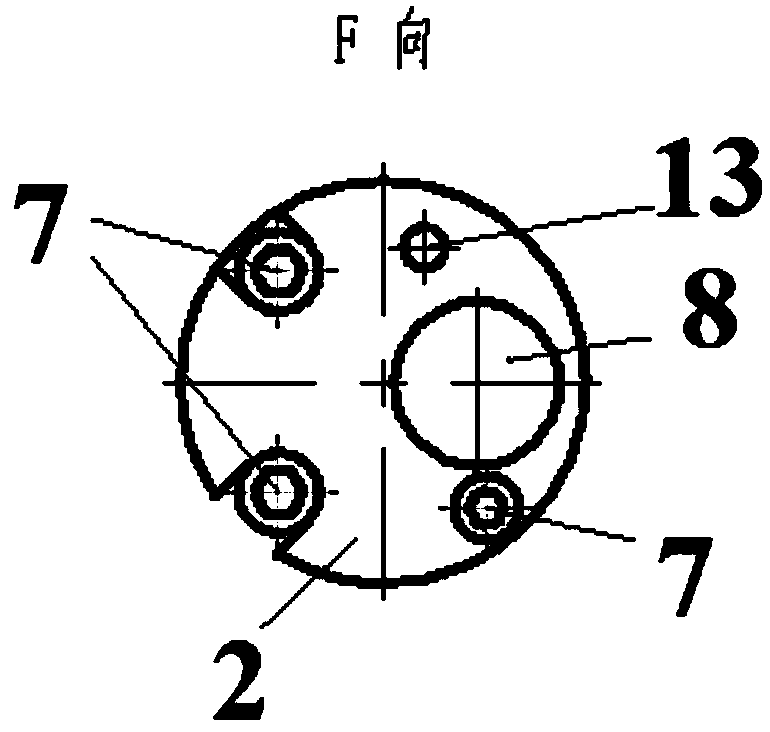

[0028] As a specific solution of this embodiment, the head end of the knife rod 1 is provided with a female plug joint 5, and the tail end of the knife body 2 is provided with a male plug joint 6, and the male plug joint 6 and the female plug joint 5 makes the cutter body 2 and the cutter body 1 installed together; the cutter body 1 and the cutter body 2 are also connected by the cutter body fixing bolt 7.

[0029] As a preferred solution of this embodiment, the first cutter head installation hole 8 is processed on the cutter body 2, and the first cutter head fastening bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com