Rolling bearing

A rolling bearing and rolling contact technology, applied in the field of rolling bearings, can solve the problems of moisture intrusion into bearings, achieve the effect of suppressing the reduction of bearing life and excellent rolling fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

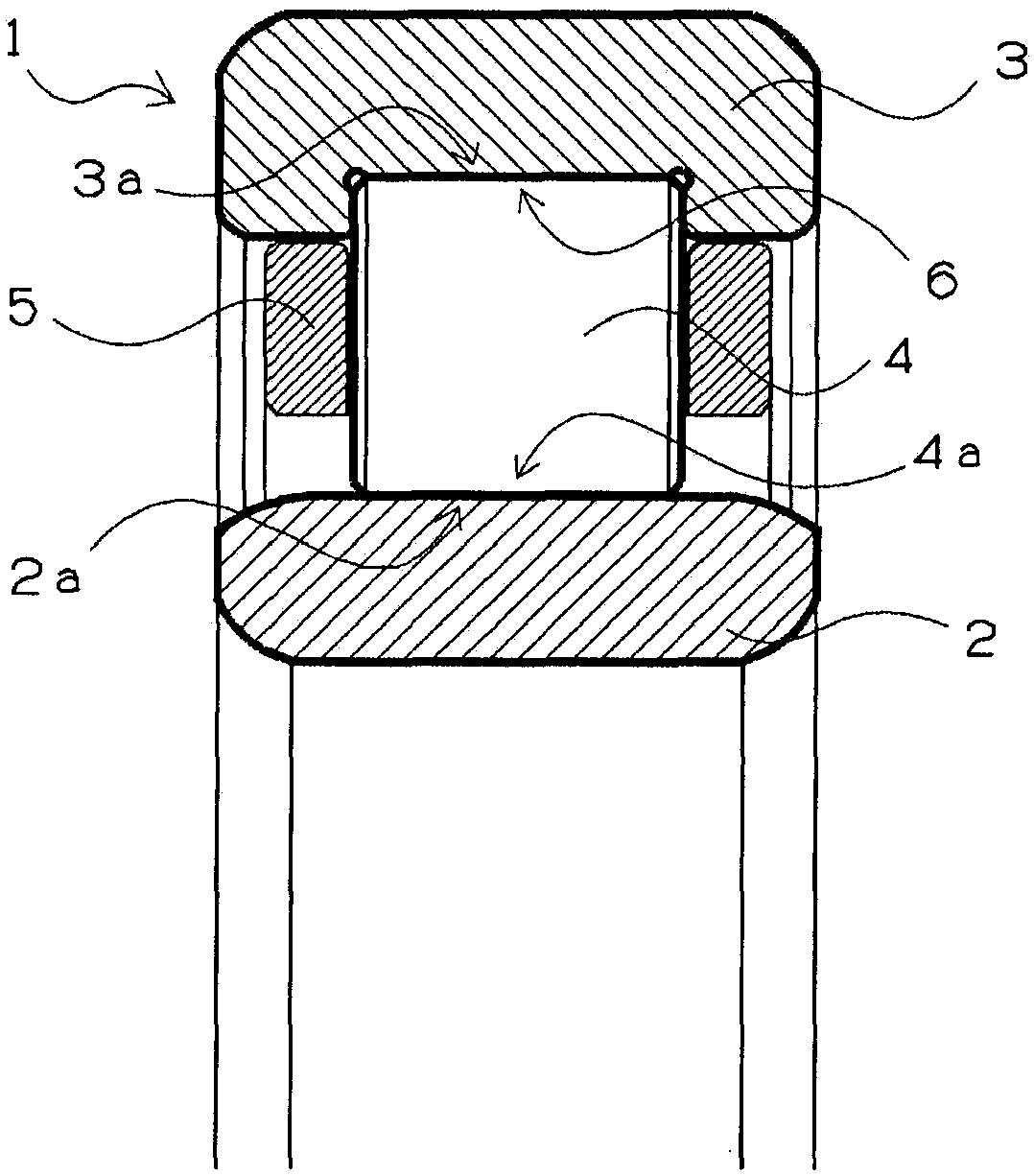

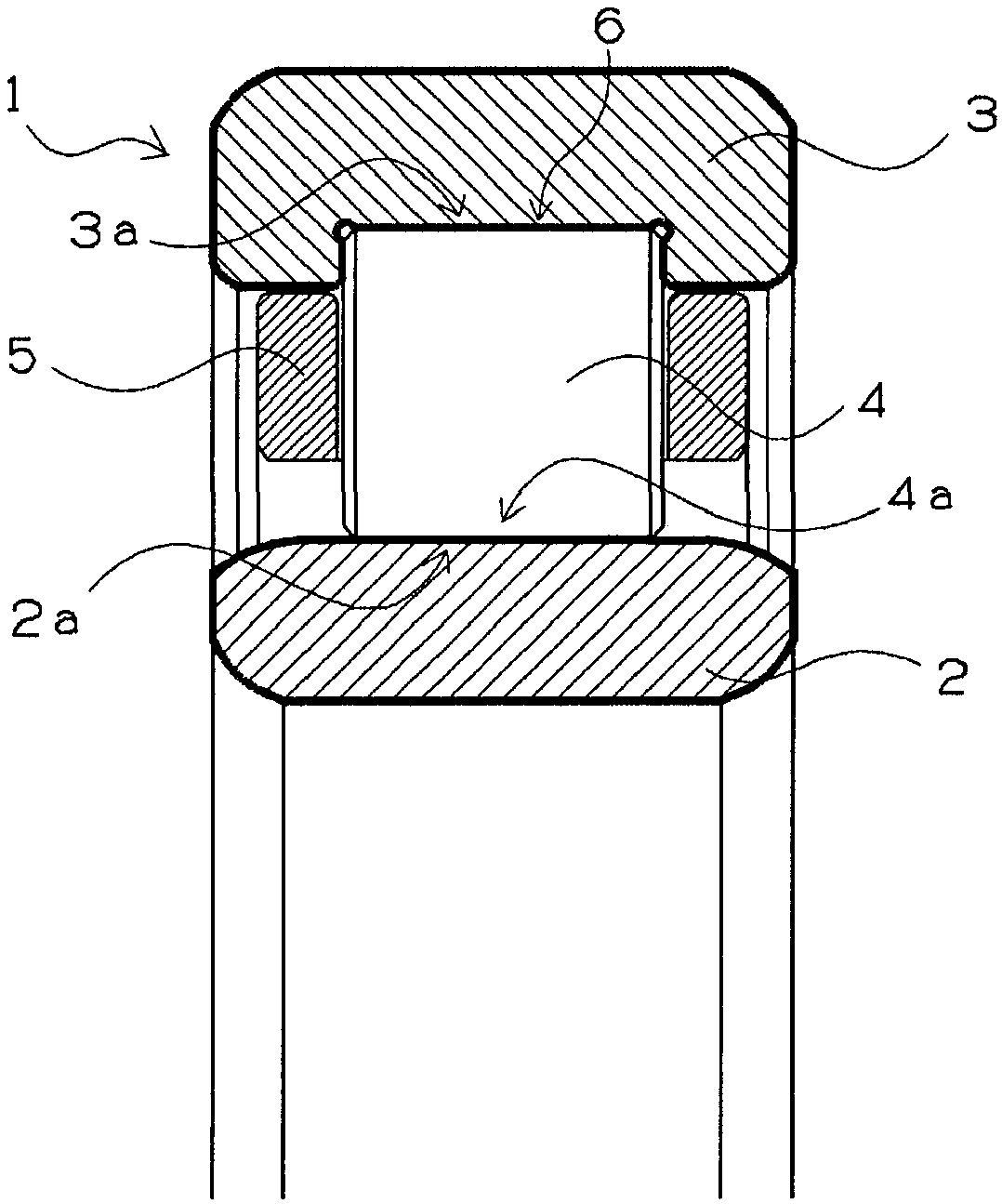

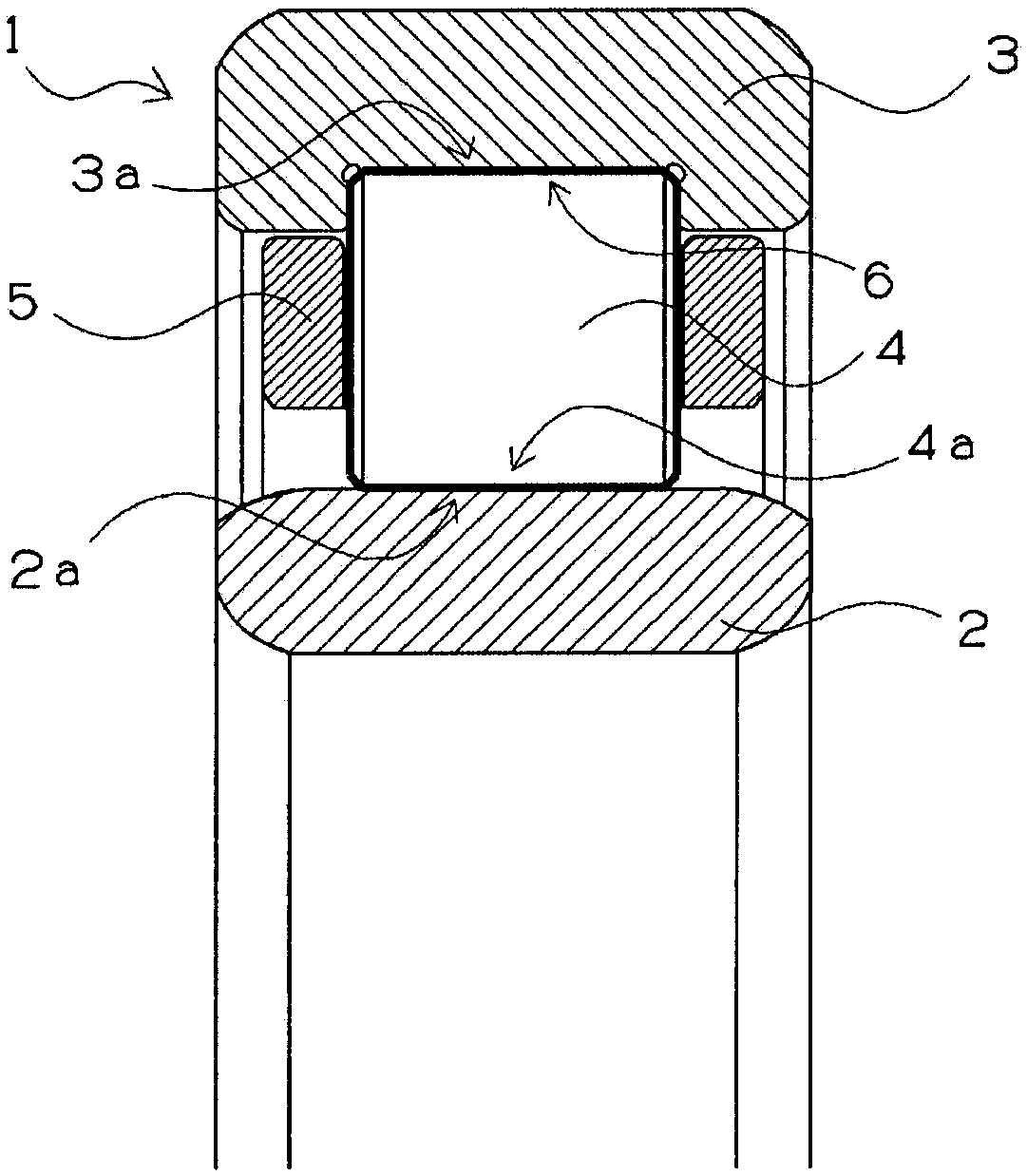

Image

Examples

Embodiment

[0039] A test piece was prepared by applying coating treatment to a cylindrical roller (bearing steel). The phosphate coating to be formed is a manganese phosphate coating, and is formed by immersing the above-mentioned cylindrical roller in a manganese phosphate treatment solution. A plurality of test pieces having different film thicknesses and crystal sizes were prepared by changing various conditions.

[0040] For this test piece, the steam turbine oil VG68 was forced to circulate oil at a contact surface pressure of 4.16GPa and a load speed of 20400cpm under the line contact of the cylindrical rollers, and the load time until peeling occurred was measured. Resistance to rolling fatigue (peel time (min)). The relationship between film thickness and peeling time is shown in Figure 4 In, the crystal size (projected area 25μm 2 The relationship between the above crystallization ratio) and the peeling time is shown in Figure 5 , the film thickness and crystal size (proje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com