Sectional tube nest cooling device in decomposing tank

A technology of cooling device and decomposition tank, which is applied in fixed tubular conduit components, alumina/aluminum hydroxide, heat exchanger types, etc., can solve the problems of easy abrasion of wide plates, complicated operation, and scarring of slurry. , to prevent the surface of the pipeline from scarring, reduce the lift, and reduce the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

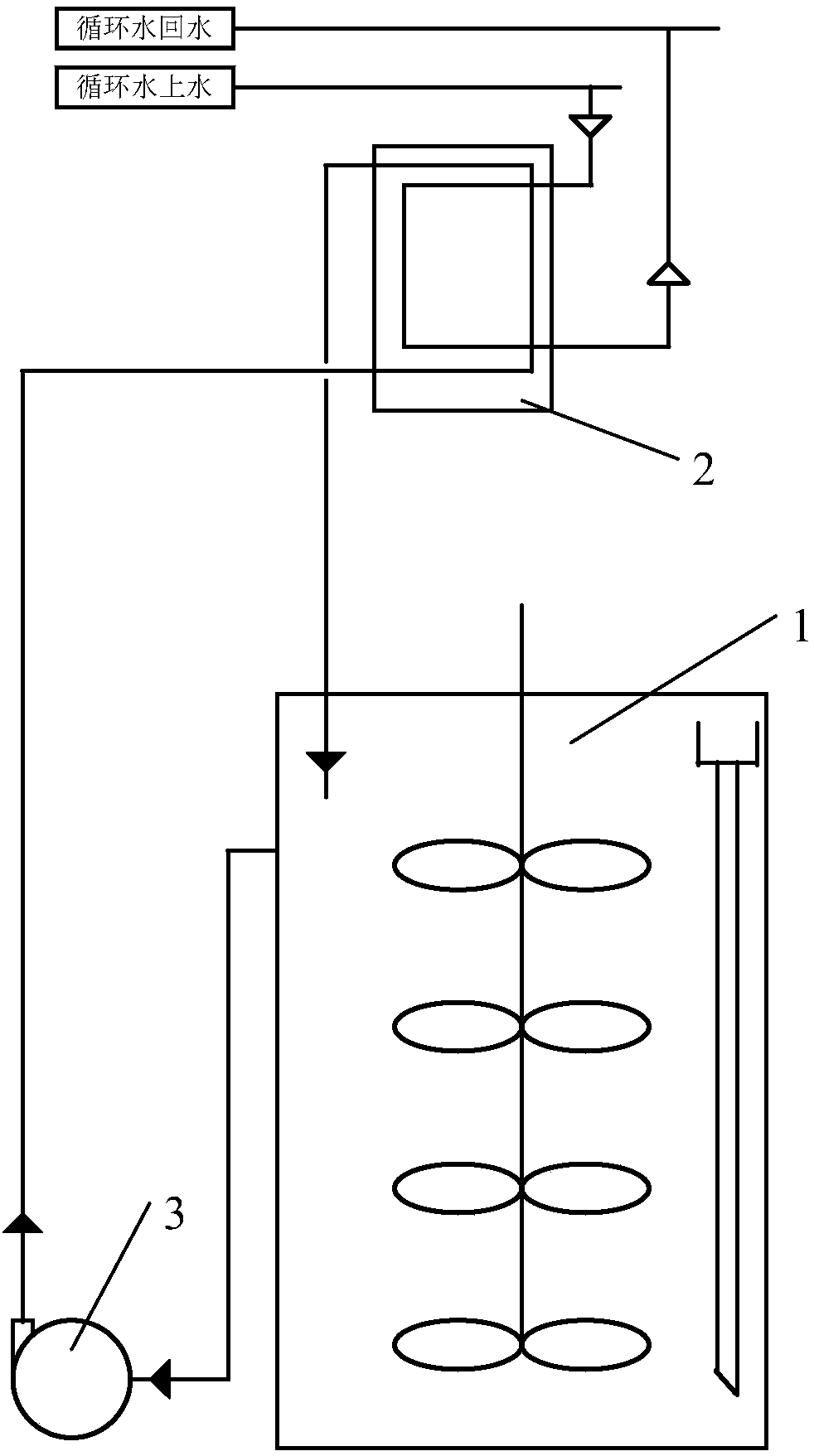

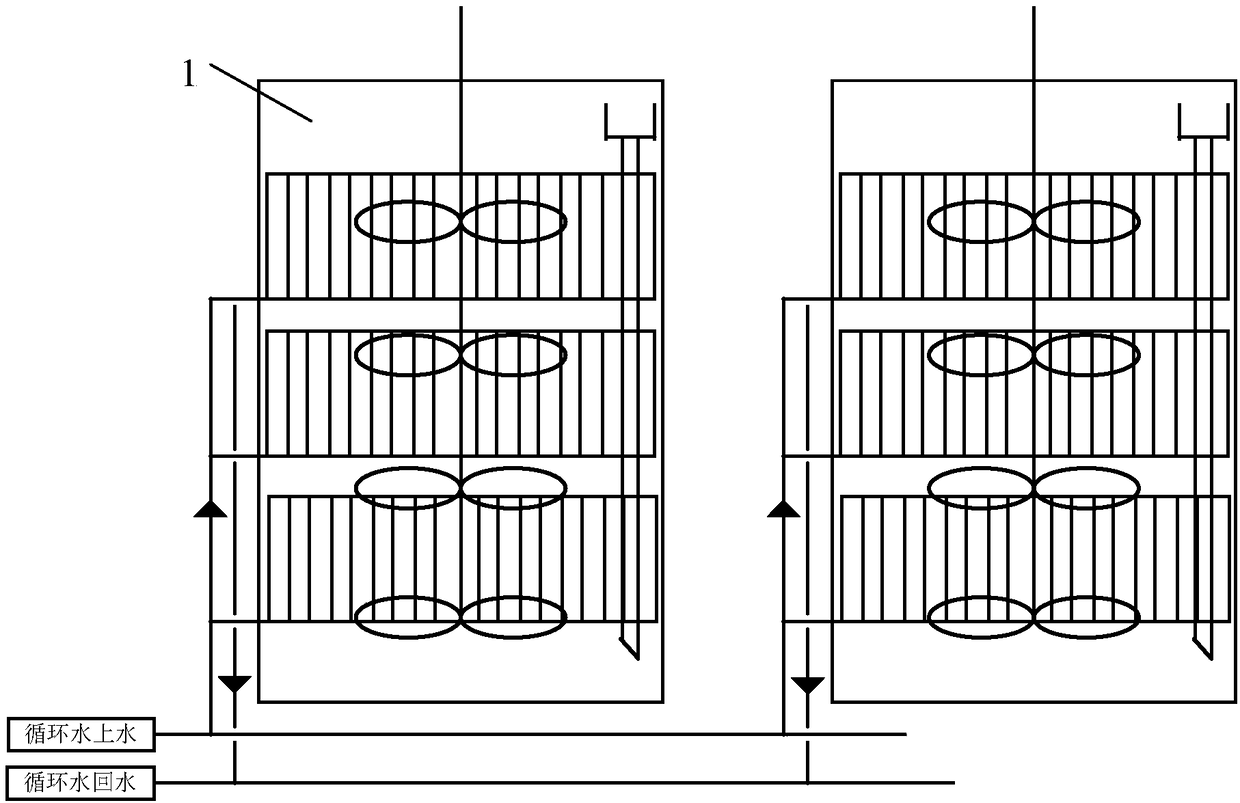

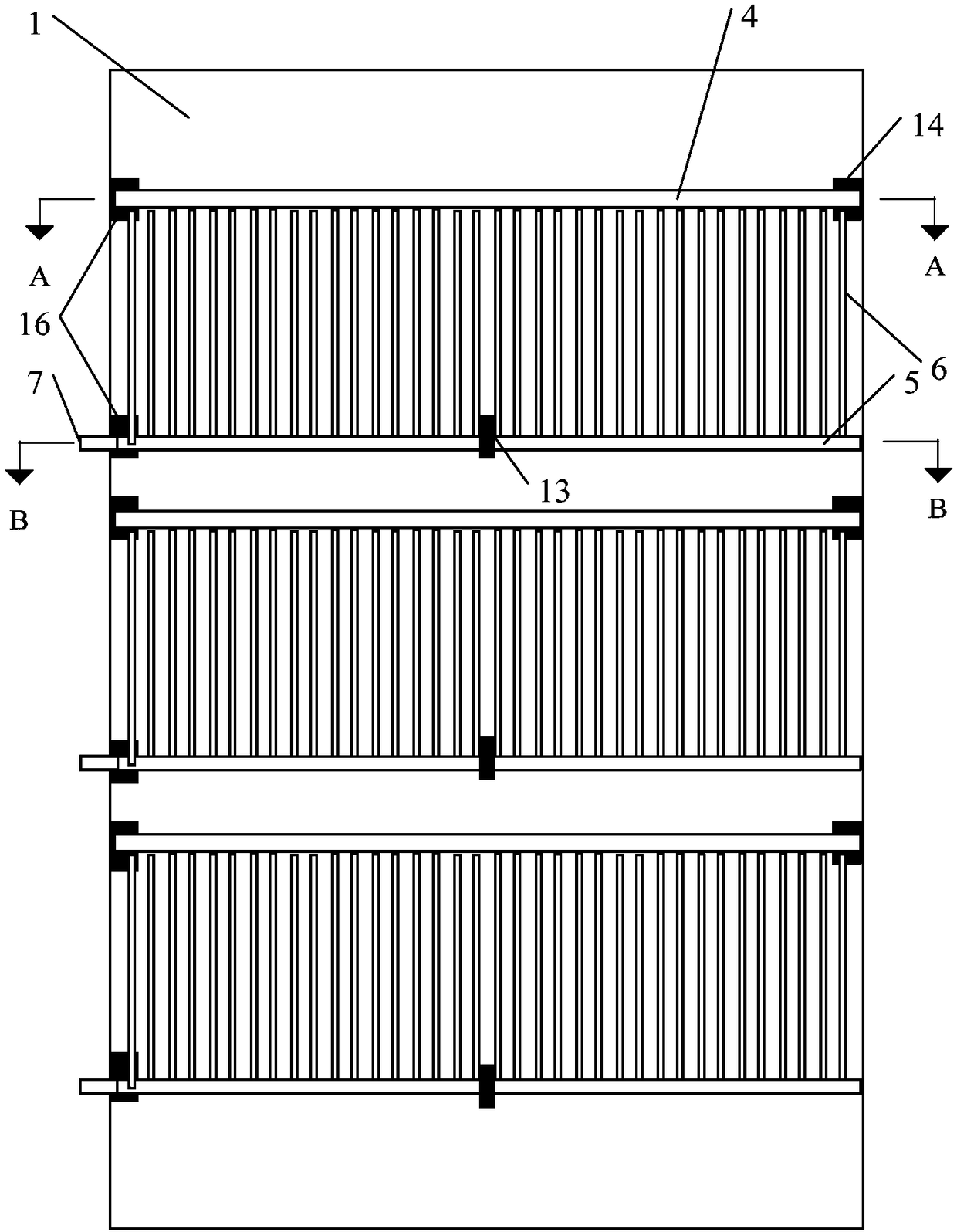

[0030] The segmented tube cooling device in the decomposition tank such as figure 2 As shown, three sections of cooling tubes are arranged in each decomposition tank 1, and the structure of a single decomposition tank is as follows image 3 As shown, its A-A surface structure is as Figure 4 As shown, the B-B surface structure is as Figure 5 As shown, the decomposition tank is divided into 3 sections of heat exchange areas from top to bottom, each section of heat exchange area is equipped with a section of cooling tubes, and each section of cooling tubes in the same decomposition tank is connected in parallel;

[0031] Each section of cooling tubes is composed of an upper ring tube 4, a lower ring tube 5, and a tube bundle between them. The tube bundle is composed of several vertical tubes 6 parallel to the axis of the decomposition tank. 4 is connected, and the bottom end is connected with the lower ring pipe 5; the water inlet 7 of each section of the cooling tube is con...

Embodiment 2

[0041] The segmented tube cooling device in the decomposition tank is the same as that in Embodiment 1, the difference is that:

[0042] (1) Each decomposition tank is equipped with 4 sections of cooling tubes, and the decomposition tank is divided into 4 sections of heat exchange zones from top to bottom;

[0043] (2) The height of the cooling tubes in each section is 5.25m, and the distance between the upper and lower adjacent cooling tubes is 0.75m; the heat exchange area of each section is 300m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com