An oil seal processing device

A processing device and oil seal technology, which can be used in grinding drive devices, metal processing equipment, grinding/polishing safety devices, etc., and can solve problems such as cumbersome operation, troublesome, adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further detailed explanation through specific implementation mode below:

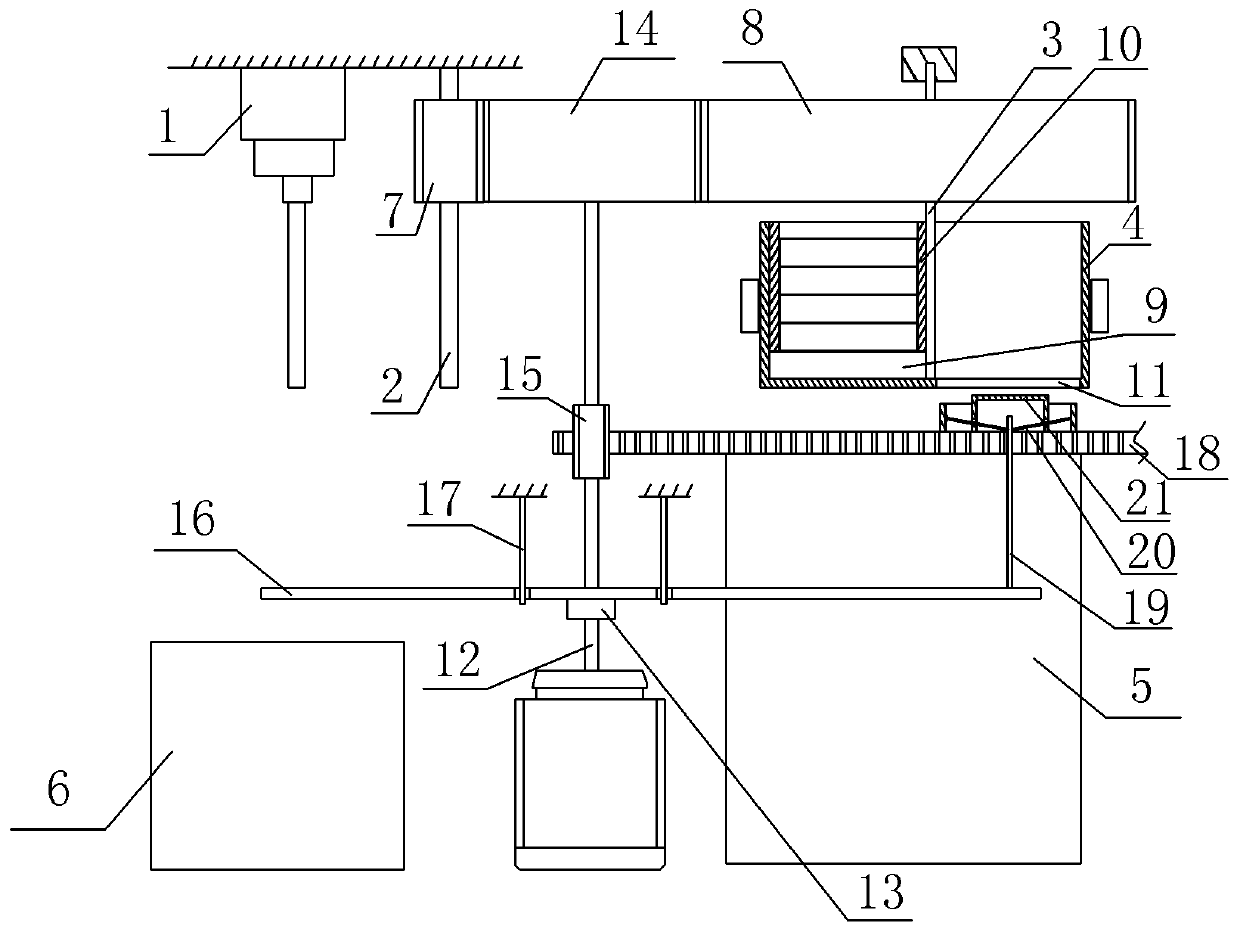

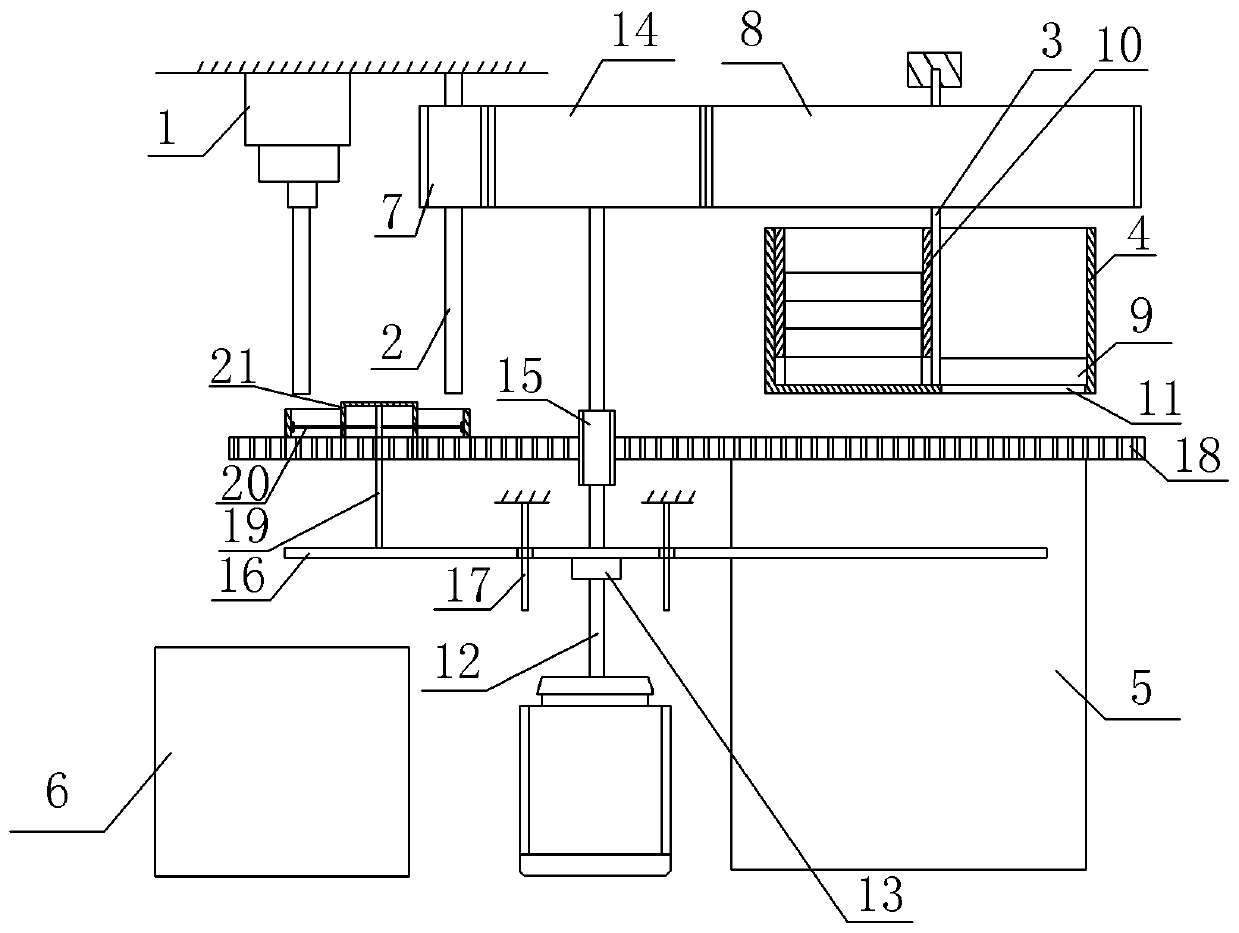

[0016] The reference signs in the drawings of the description include: swing cylinder 1, grinding rod 2, vertical rod 3, delivery box 4, support platform 5, collection box 6, No. 1 gear tube 7, No. 1 gear 8, and delivery plate 9 , Put piece tube 10, opening 11, screw mandrel 12, nut seat 13, No. 2 gear 14, No. 2 gear tube 15, resisting plate 16, limit rod 17, rack 18, resisting rod 19, stretch rod 20, Resist tube 21 .

[0017] Such as figure 1 , 2 The shown oil seal processing device includes a swing cylinder 1 , a grinding rod 2 , a vertical rod 3 , a box 4 , a stretching mechanism, a support table 5 , a screw pair, a servo motor and a collection box 6 .

[0018] Swing cylinder 1 and putting case 4 are fixed on the frame, and polishing bar 2 is rotated and arranged on the frame, and a gear pipe 7 is coaxially fixed on the polishing bar 2 . The upper end of the vertical bar 3 is rotated and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com