Building material cutting device

A technology for cutting devices and building materials, applied in shearing devices, maintenance and safety accessories, shearing machine equipment, etc., can solve the problems of increasing labor burden, reducing cutting efficiency, falling, etc., to solve the burden of regularly replacing filters manually , The effect of improving cutting efficiency and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

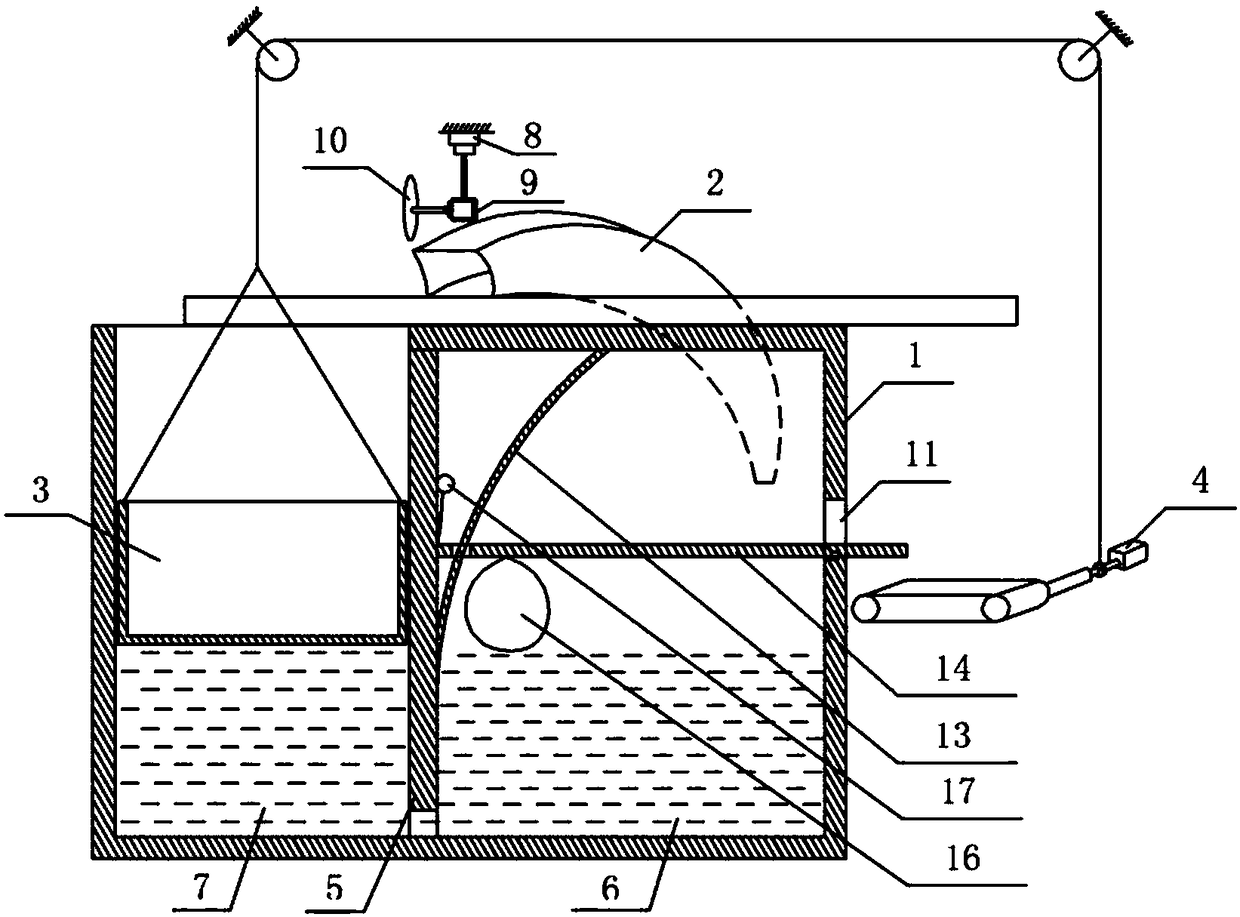

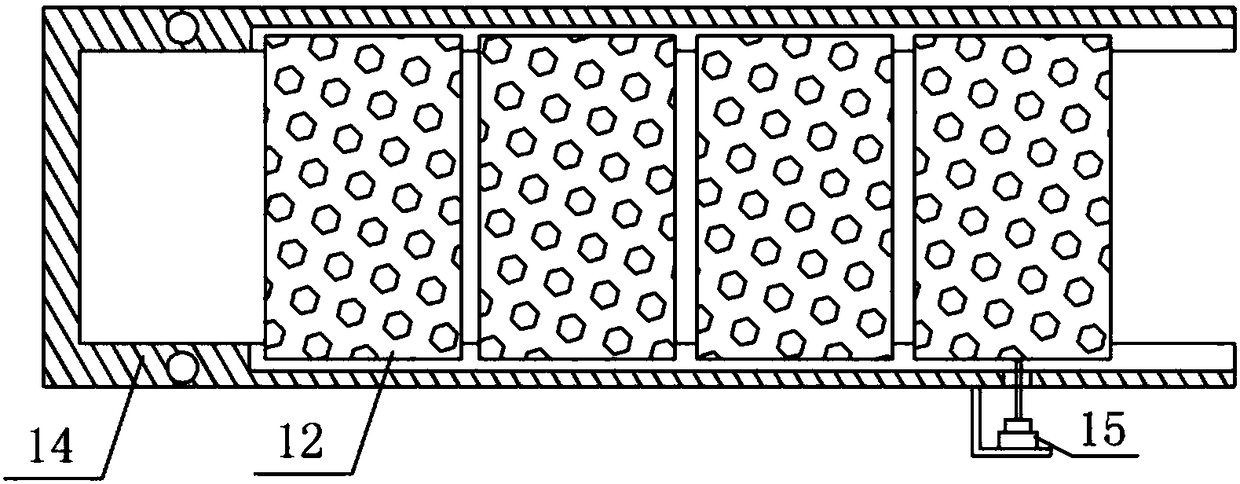

[0015] The reference signs in the drawings of the description include: support chamber 1, chip guide channel 2, collection box 3, servo motor 4, partition 5, chip collection chamber 6, collection chamber 7, lifting cylinder 8, stepping motor 9, Cutter 10, opening 11, square frame 12, arc bar 13, support bar 14, cylinder 15, air bag 16, switch 17, pay-off rack 18.

[0016] Such as figure 1 , 2 The building material cutting device shown includes a supporting chamber 1 , a cutting mechanism, a removing mechanism, a conveying mechanism, a rotating mechanism, a chip guide channel 2 , a collecting box 3 , a servo motor 4 and a partition 5 . The partition 5 divides the support chamber 1 into the chip collecting chamber 6 on the right and the collecting piece chamber 7 on the left. The bottom of the chip collecting chamber 6 and the collecting piece chamber 7 is connected. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com