Capsule automatic sorting device

An automatic sorting and capsule technology, which is applied in solid separation, cleaning method using gas flow, filtering and sieving, etc., can solve problems such as unguaranteed product pass rate, impact on hygienic quality of capsules, manual sorting and sorting errors, etc., to achieve Reduce the process of sorting and placing, reduce the labor intensity of workers, and ensure the effect of hygiene and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

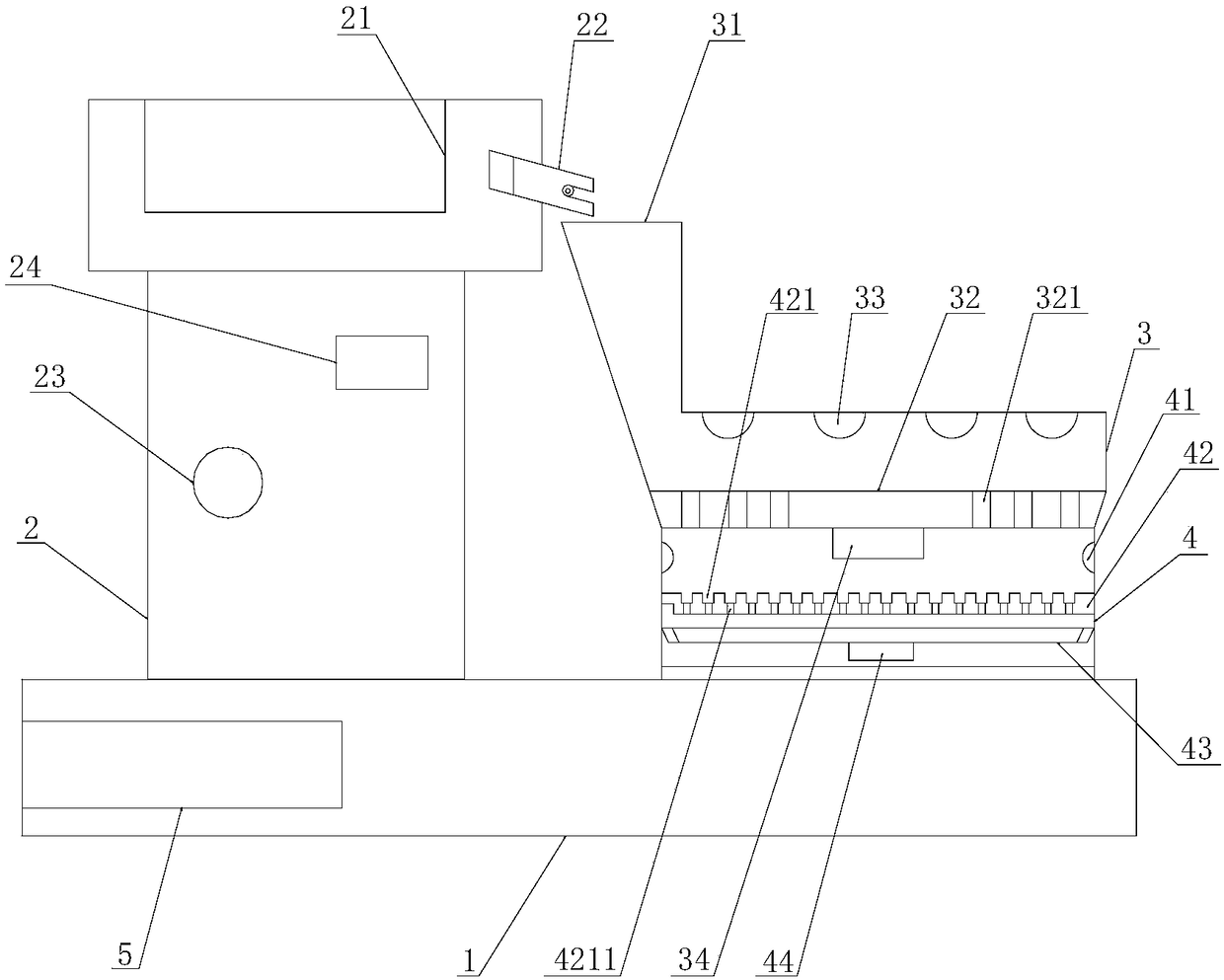

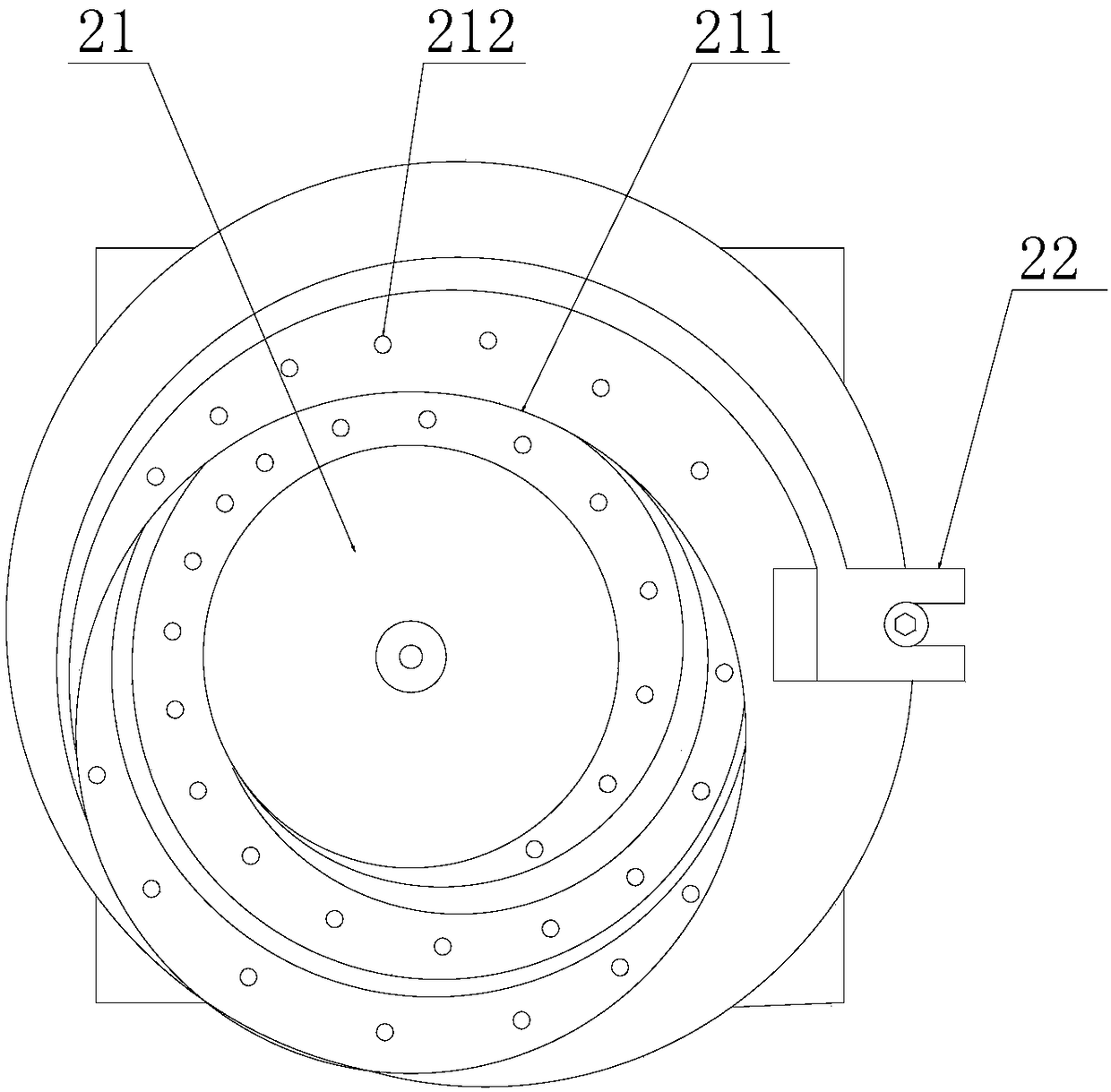

[0014] refer to figure 1 with figure 2 , an automatic capsule sorting device of the present invention, comprising a base 1, a feeding mechanism 2, a first sorting mechanism 3, a second sorting mechanism 4 and a control mechanism 5, the feeding mechanism 2 is installed and fixed on the base 1, a second sorting mechanism 4 is provided below the first sorting mechanism 3, and the second sorting mechanism 4 is installed and fixed on the base 1. The feeding mechanism 2, the first sorting mechanism 3. The second sorting mechanism 4 cooperates with each other. The base 1 is also provided with a control mechanism 5. The feeding mechanism 2, the first sorting mechanism 3, and the second sorting mechanism 4 are connected to the control mechanism 5. The feeding mechanism 2 includes a vibrating plate 21 and a feeding plate 22, the vibrating plate 21 is connected to the feeding plate 22, and the vibrating plate 21 and the feeding plate 22 cooperate with each other to transport the capsul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com