Double vertical shaft deep ploughing machine

A deep tiller and vertical shaft technology, which is applied in the fields of tillage machines, agricultural machines and implements, etc. It can solve the problems of large damage to soil granules, impossibility of plowing, large traction resistance, etc., and achieve high tillage quality, light weight, The effect of small supporting power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

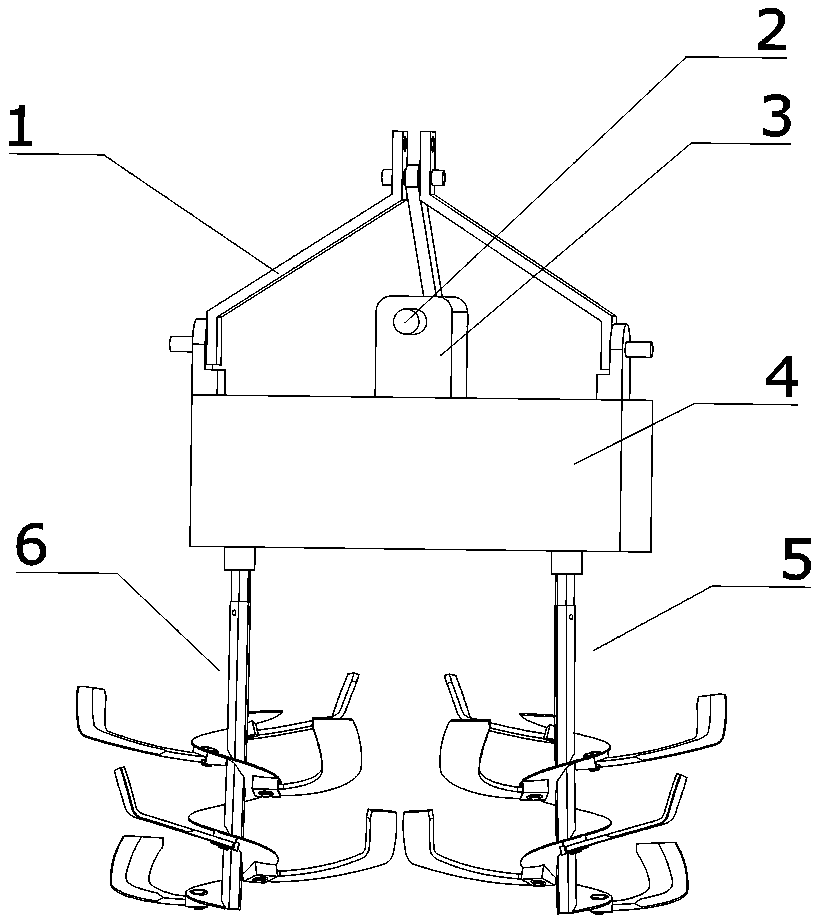

[0030] Below in conjunction with accompanying drawing, the present invention is further described: as Figure 1-7 As shown, when performing deep plowing operations, the double vertical shaft plowing machine patented by the present invention is connected to the traction power machine through a three-point suspension mechanism 1, and the power required for rotary plowing is input from the power input shaft 2, and after being shifted by the transmission 3, it is then transferred. The device 4 divides the power into two and outputs it to the first vertical shaft deep tillage mechanism 5 and the second vertical shaft deep tillage mechanism 6 respectively, and makes them rotate in opposite directions respectively, that is, the first vertical shaft deep tillage mechanism 5 rotates clockwise, and the second vertical shaft deep tillage mechanism 6 rotates clockwise. Two vertical shaft type deep plowing mechanisms 6 rotate counterclockwise.

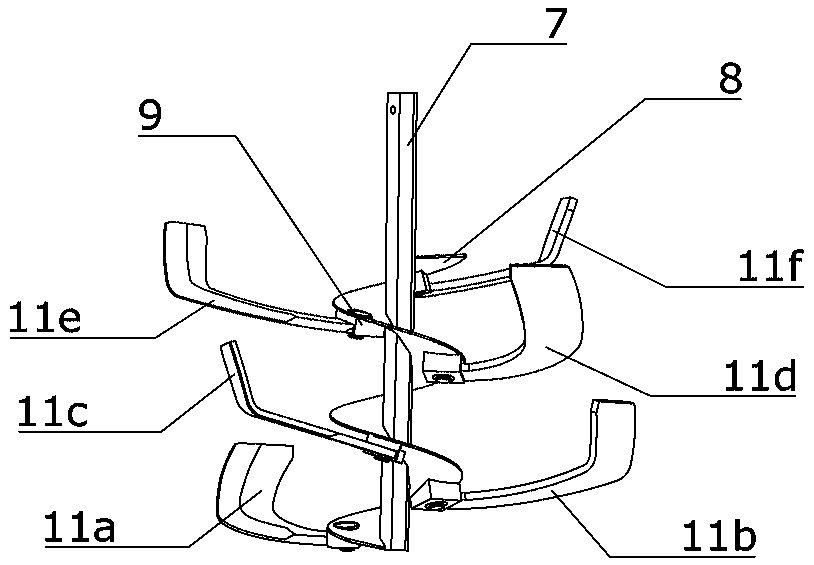

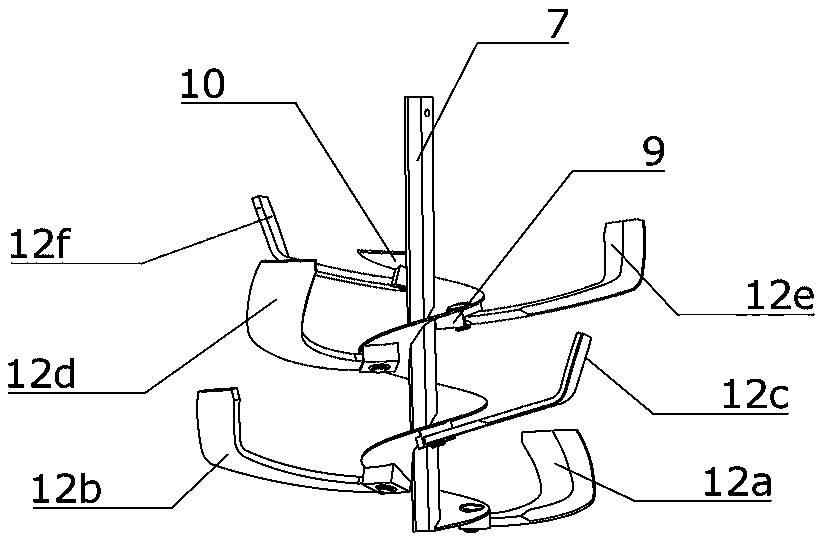

[0031] The first vertical shaft type deep pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com