Device and method for dyeing dacron fabric and application of dacron fabric

A technology of a dyeing device and a dyeing method, applied in the textile field, can solve the problems of rising water level in a dye vat, long process time, and inability to control the temperature of clean water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

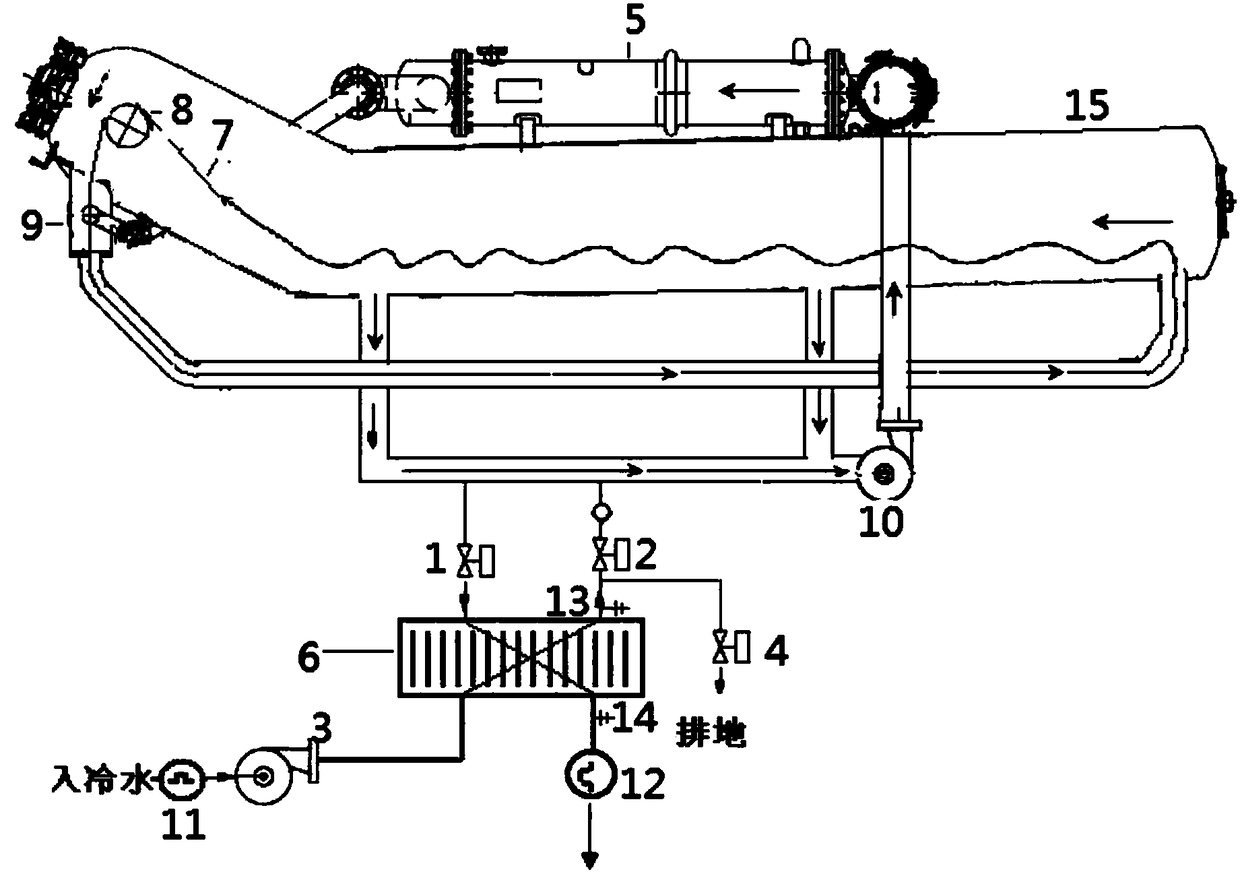

[0061] A dyeing device for polyester fabric, such as figure 1 Shown, comprise dye vat heat exchanger 5, dye vat 15 and plate heat exchanger 6 connected in sequence;

[0062] The plate heat exchanger PLC controller is connected with the pressure transmitter; the dye vat 15 and the dye vat heat exchanger 5 are controlled by the dye vat PLC controller; the plate heat exchanger 6 is controlled by the plate heat exchanger PLC controller; the inside of the dye vat 15 is equipped with The pressure transmitter, the PLC controller of the plate heat exchanger and the PLC controller of the dyeing vat are connected through a signal transmitter;

[0063] The dyeing vat 15 is provided with a dye liquor circulation pipeline, and the dye liquor circulation pipeline is provided with a hot water discharge branch, a hot water inlet branch and a dye vat main circulation pump 10 along the dye liquor flow direction; the hot water discharge branch is provided with The hot water discharge valve 1 an...

Embodiment 2

[0065] A method for dyeing polyester fabrics with disperse dyes is carried out using the device provided in Example 1.

[0066] Polyester fabric: pure polyester 50D / 75F, knitted double-sided fabric, width 160cm, weight 95g / m 2 .

[0067] Disperse dye formula:

[0068] Disperse Red S-2R / %(owf): 0.100

[0069] Disperse blue BG / %(owf): 0.055

[0070] Disperse navy blue SG / %(owf): 0.2340

[0071] Proceed as follows:

[0072] 1) Program the dyeing program and overflow washing program in the PLC controller of the dyeing vat;

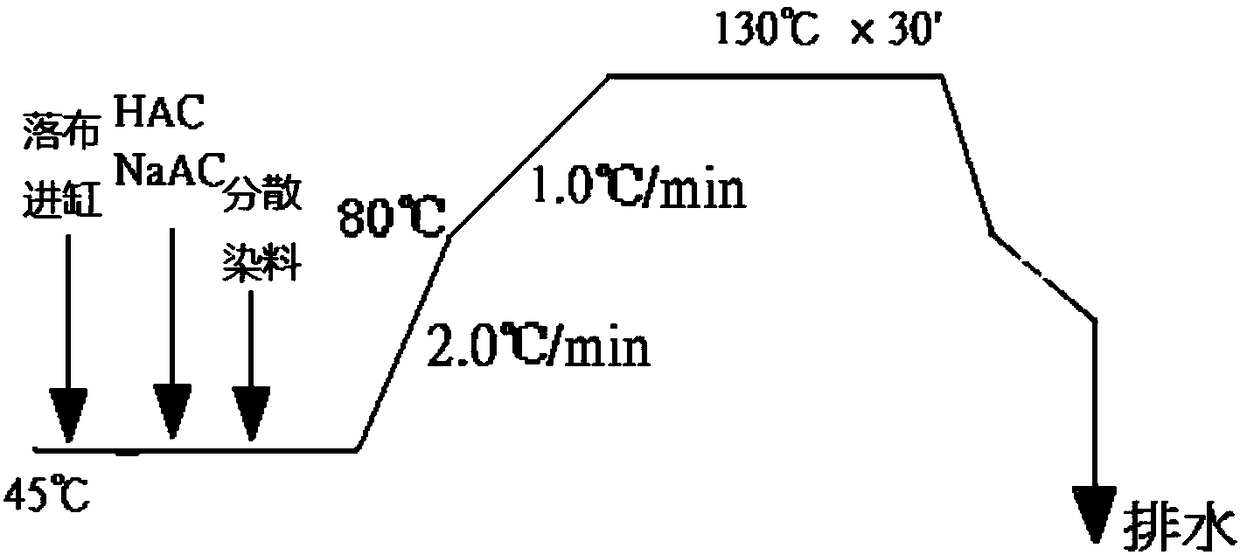

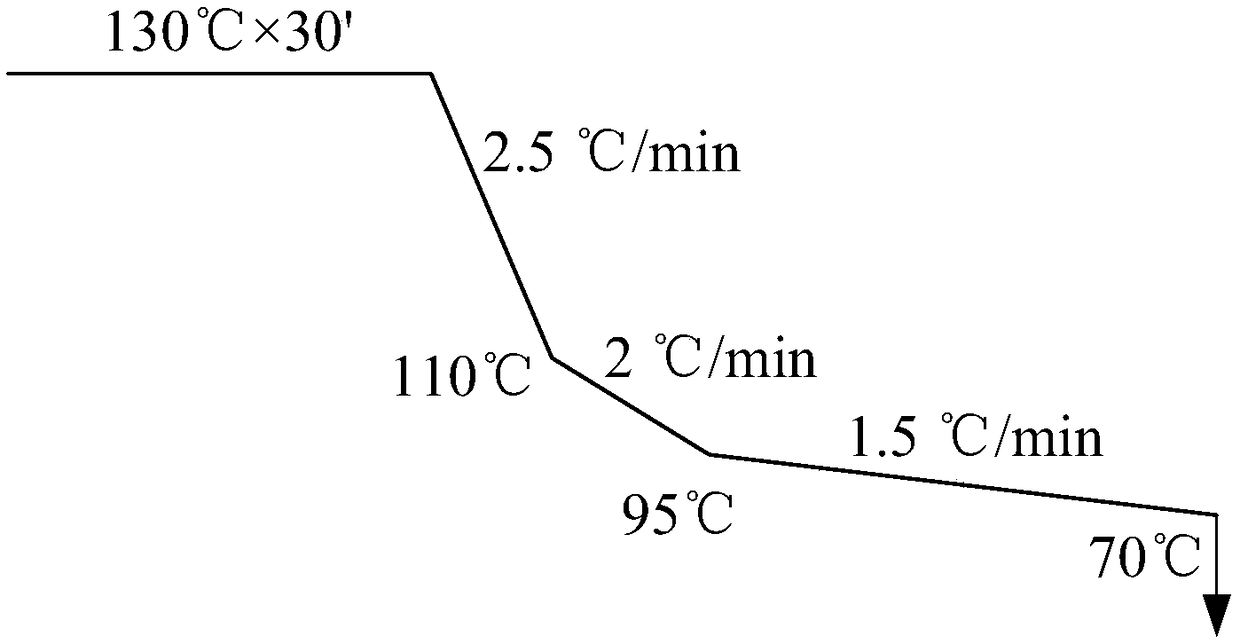

[0073] 2) Start the dyeing program, the dyeing vat PLC controller controls the dyeing vat heat exchanger 5 and the dyeing vat 15 for dyeing; specifically: the polyester fabric 7 that is degreased by the open width machine and pre-shaped falls into the dyeing vat 15 (Taiwan Asia Rocky AK-DSL dyeing vat 15), add water to soak the polyester fabric 7, heat up to 45°C, as figure 2 As shown, after diluting and mixing the disperse dye in the auxiliary vat eve...

Embodiment 3

[0093] A method for dyeing polyester fabrics with disperse dyes is carried out using the device provided in Example 1.

[0094] Polyester fabric: pure polyester 50D / 144F, knitted double-sided fabric, width 160cm, weight 95g / m 2 .

[0095] Disperse dye formula:

[0096] Disperse Yellow S-2R / %(owf): 0.233

[0097] Disperse Red WBRT7 / % (owf): 0.360

[0098] Disperse blue RDE / %(owf): 0.083

[0099] The steps are the same as in Example 2 except that the pH of the dye solution is adjusted to 4.1 and the bath ratio is controlled to be 1:8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com