Nanometer titania antibacterial plastic and production process thereof

A technology of nano-titanium dioxide and antibacterial plastics, applied in the field of antibacterial plastics, can solve the problems of difficult dispersion, shedding and shedding of titanium dioxide particles, and achieve the effect of improving antibacterial durability, uniformity and dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

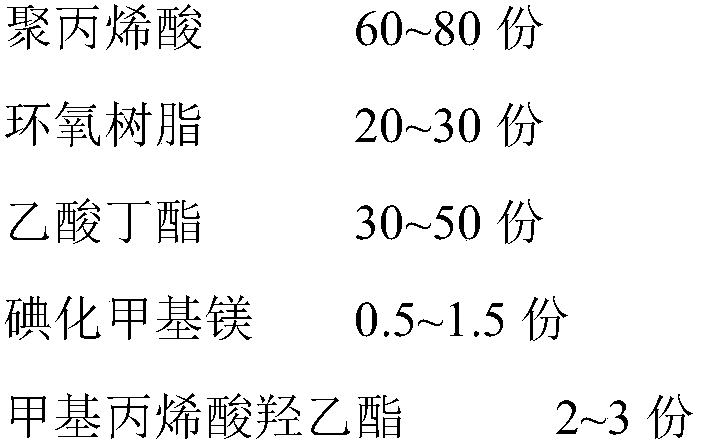

[0042] Step 1: Preparation of Epoxy Modified Resin

[0043] (1) According to the formula, weigh 380g of polyacrylic acid, 285g of epoxy resin, 285g of butyl acetate, 5g of methylmagnesium iodide and 14g of hydroxyethyl methacrylate. Mix to obtain the first mixture, then mix the epoxy resin with methylmagnesium iodide to obtain the second mixture, mix the first mixture, the second mixture and butyl acetate and react at 100°C for 3h, Obtain epoxy-modified resin, stand-by;

[0044] The second step: surface treatment of nano-titanium dioxide:

[0045] (1) Weigh 4.2 g of nano-titanium dioxide and 8.4 g of water, and mix them uniformly under ultrasonic treatment, so that the nano-titanium dioxide is quickly dispersed, the mixing temperature is 60 ° C, and the mixing time is 20 minutes to obtain a titanium dioxide dispersion;

[0046] (2) Weigh 4.2 g of hydroxyethyl quaternary ammonium salt, add it into the titanium dioxide dispersion and mix, and continue to mix with ultrasonic co...

Embodiment 2

[0060] Step 1: Preparation of Epoxy Modified Resin

[0061] (1) Weigh respectively 432g of polyacrylic acid, 356g of epoxy resin, 285g of butyl acetate, 9g of methylmagnesium iodide and 20g of hydroxyethyl methacrylate, first mix polyacrylic acid and hydroxyethyl methacrylate to obtain the first One mixture, then epoxy resin is mixed with methylmagnesium iodide to obtain a second mixture, the first mixture, the second mixture and butyl acetate are mixed and reacted at 110°C for 5h to obtain epoxy Modified resin, ready for use;

[0062] The second step: surface treatment of nano-titanium dioxide:

[0063] (1) Weigh 7.5 g of nano-titanium dioxide and 14 g of water, and mix them uniformly under ultrasonic treatment, so that the nano-titanium dioxide is quickly dispersed, the mixing temperature is 70 ° C, and the mixing time is 40 minutes to obtain a titanium dioxide dispersion;

[0064] (2) Weigh 7.5g of hydroxyethyl quaternary ammonium salt, add it into the titanium dioxide di...

Embodiment 3

[0078] Step 1: Preparation of Epoxy Modified Resin

[0079] (1) Weigh respectively 521g of polyacrylic acid, 278g of epoxy resin, 256g of butyl acetate, 10g of methylmagnesium iodide and 25g of hydroxyethyl methacrylate, first mix polyacrylic acid and hydroxyethyl methacrylate to obtain the first One mixture, then epoxy resin is mixed with methylmagnesium iodide to obtain a second mixture, the first mixture, the second mixture and butyl acetate are mixed and reacted at 110°C for 5h to obtain epoxy Modified resin, ready for use;

[0080] The second step: surface treatment of nano-titanium dioxide:

[0081] (1) Weigh 4.7 g of nano-titanium dioxide and 14 g of water, and mix them uniformly under ultrasonic treatment, so that the nano-titanium dioxide is quickly dispersed, the mixing temperature is 70 ° C, and the mixing time is 40 minutes to obtain a titanium dioxide dispersion;

[0082] (2) Weigh 4.7g of hydroxyethyl quaternary ammonium salt, add it into the titanium dioxide d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com