A Simple Back Calculation Method for Measuring Casting Interface Heat Transfer Coefficient

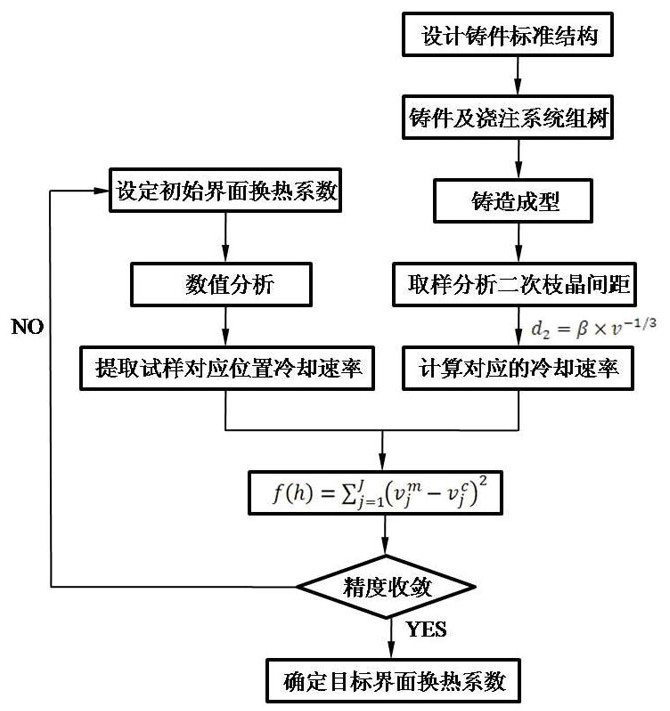

A simple and convenient technology for interface heat transfer coefficient, which can be used in calculations, computer-aided design, CAD numerical modeling, etc., and can solve problems such as difficult operation, high cost, and cumbersome process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In this embodiment, the casting is formed by the method of investment precision casting. The casting structure is a cylinder of Φ20×80, and the tree diagram of the casting and gating system can be found in figure 1 .

[0031] The present invention comprises the following sequential steps:

[0032] 1) Design a casting 1 with a cylindrical structure of Φ20×80, which has the characteristics of simple structure, convenient forming, and easy sampling;

[0033] Generally speaking, the mold-casting interface has an irregular shape, and the heat transfer coefficients at different positions on the interface are not the same, which brings difficulties to the measurement. Therefore, cylindrical or flat castings are generally used to measure the interface heat transfer coefficient. In order to reduce the influence caused by the inhomogeneity of the interface heat transfer coefficient.

[0034] 2) Design the investment casting process plan, use the tree-building method of one bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com