Novel transient recording fault indicator

A fault indicator and transient recording technology, applied in the direction of the measuring device shell, etc., can solve the problems of inconvenient plugging and unplugging, easy damage, and failure to achieve rapid detection, so as to reduce the possibility of assembly operation errors and ensure current detection Accuracy, the effect of good waterproof and dustproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

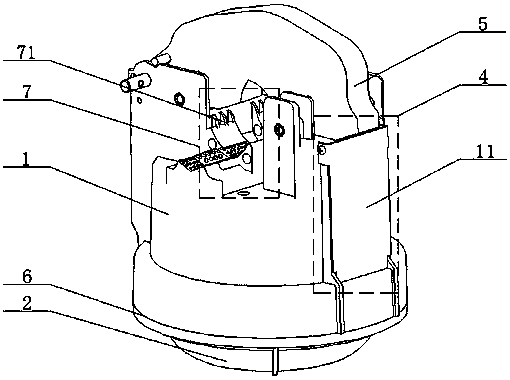

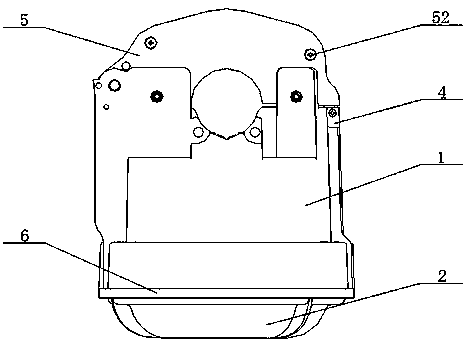

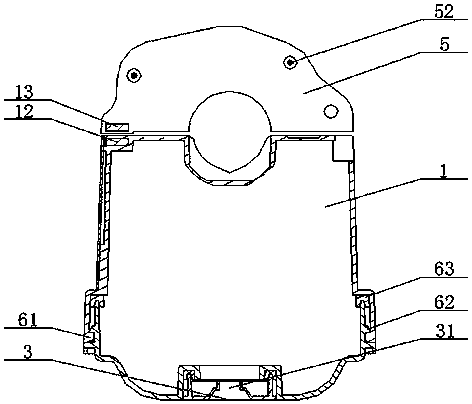

[0024] see Figure 1-Figure 7 As shown, the technical solution adopted in this specific embodiment is: it includes a main body 1, a transparent cover 2, a decorative plate 3, a magnet placement device 4, a magnetic core protective cover 5, a rotary buckle sealing device 6, an induction sheet 7, Test terminal 8; the bottom surface of the main body 1 is connected with a transparent cover 2, and the decorative plate 3 is set at the connection position between the transparent cover 2 and the main body 1; the inside of the main body 1 is provided with a magnet placement device 4, and the magnetic core protective cover 5 is set on the main body 1; the position connecting the main body 1 and the transparent cover 2 is provided with a turnbuckle sealing device 6; At the position on the main body 1, when using the new type of transient recorder type fault indicator for current fault detection, the test terminal 8 can be installed or disassembled on the main body 1, and the test termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com