Method for preparing refrigerator liner by U-shaped large and small surrounding plates and Z-shaped baseplate

A freezer liner and hoarding technology, which is used in household refrigeration devices, lighting and heating equipment, household appliances, etc., to reduce the impact force, improve the yield, and improve the riveting production rhythm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

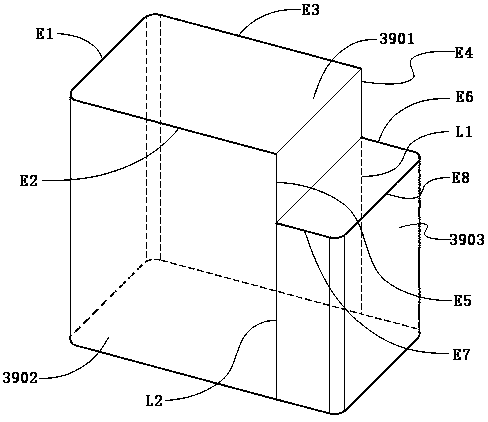

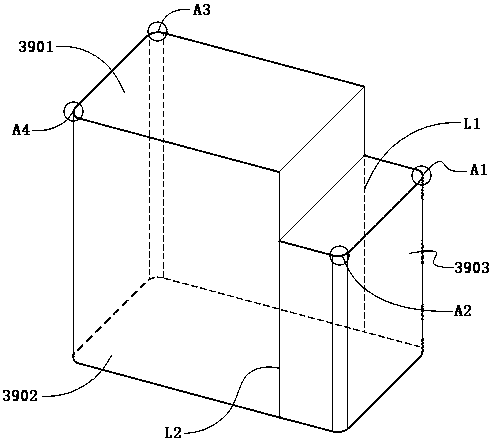

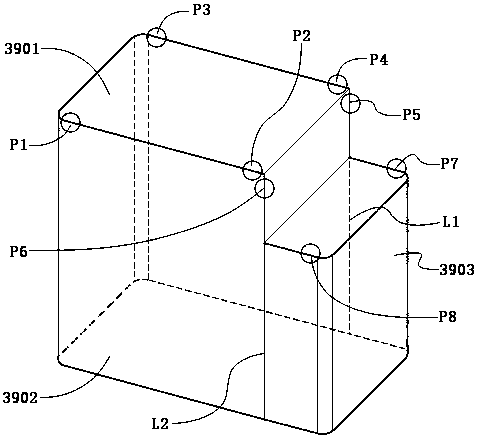

[0031] The method for preparing a refrigerator liner with U-shaped large and small panels and a Z-shaped bottom plate of the present invention is used for preparing a refrigerator liner from a U-shaped large panel, a U-shaped small panel and a Z-shaped bottom panel. Such as figure 1 , figure 2 , image 3 shown. figure 1 , figure 2 , image 3 For an upside-down freezer liner, 3901 is a Z-shaped bottom plate, 3902 is a U-shaped large enclosure, and 3903 is a U-shaped small enclosure. The U-shaped large enclosure 3902 and the U-shaped small enclosure 3903 are mutually riveted to form a mouth-shaped enclosure. L1 and L2 are two riveting lines where the U-shaped large enclosure 3902 and the U-shaped small enclosure 3903 are riveted to each other. The mouth-shaped coaming plate and the Z-shaped bottom plate 3901 are then riveted to finally become a semi-fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com