Plastic and metal combined tap handle

A faucet and plastic technology, applied in the direction of valve operation/release devices, valve details, engine components, etc., can solve the problems of environmental protection, large dust, polluted air quality, etc., and achieve the effect of reducing labor costs and not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with embodiment the present invention is further described in detail.

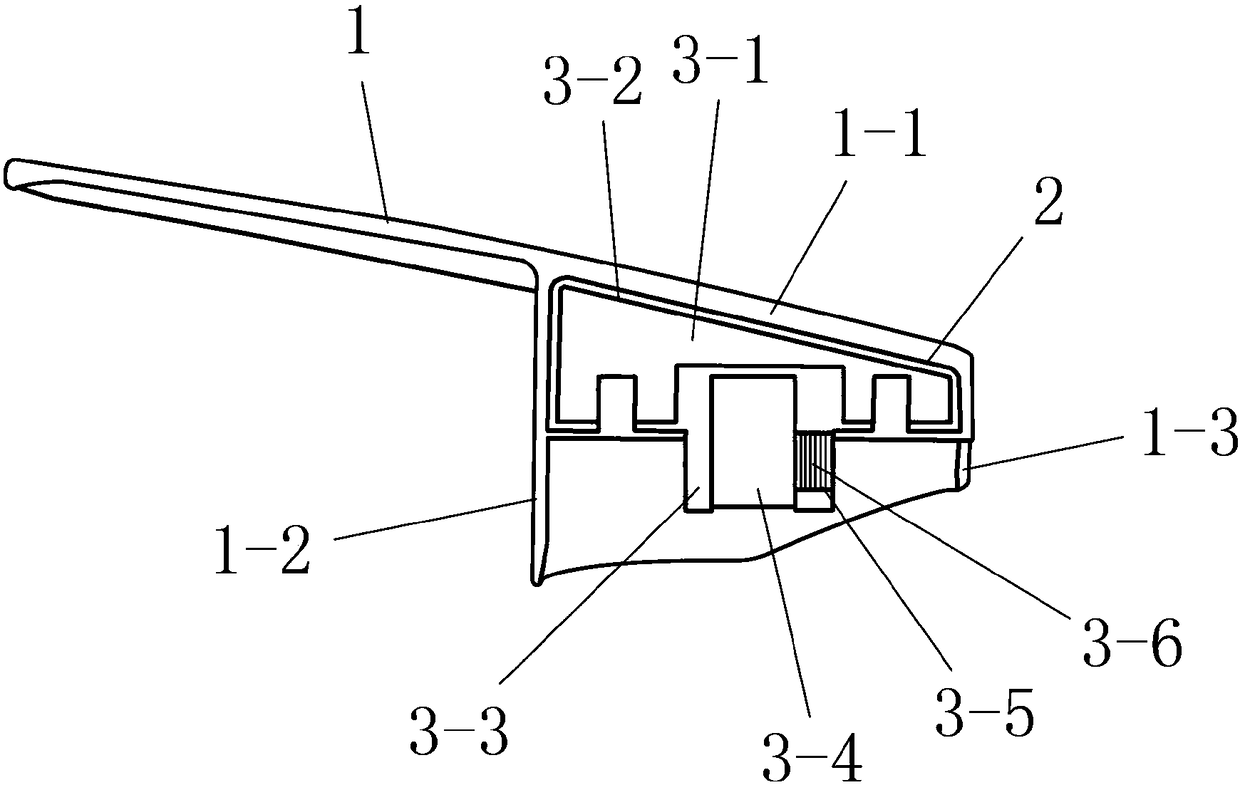

[0011] Such as figure 1 As shown, a plastic and metal faucet handle includes a plastic handle body 1, a cover body 1-1 is provided at one end of the plastic handle body 1, and a cavity 2 is provided inside the cover body 1-1. A counterweight 3 is built into the cavity 2, and the counterweight 3 includes an iron block 3-1, the iron block 3-1 is covered with a plastic shell 3-2, and the bottom of the plastic shell 3-2 is provided with a convex Out of the lower convex part 3-3 at the bottom of the cavity, the lower convex part 3-3 is provided with a valve stem insertion hole 3-4, and the rear side of the valve stem insertion hole 3-4 is provided with a through hole 3-5. A copper nut 3-6 is installed in the through hole 3-5.

[0012] A valve stem shielding portion 1-2 is provided on the front side of the cover body 1-1.

[0013] The rear side of the cover body 1-1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com