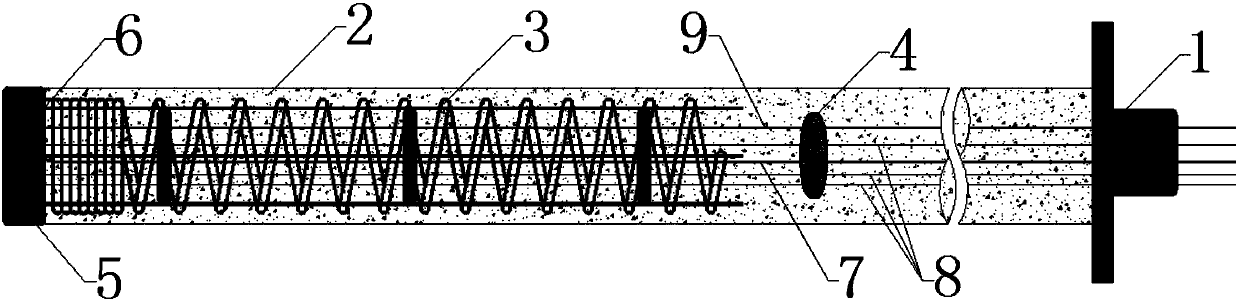

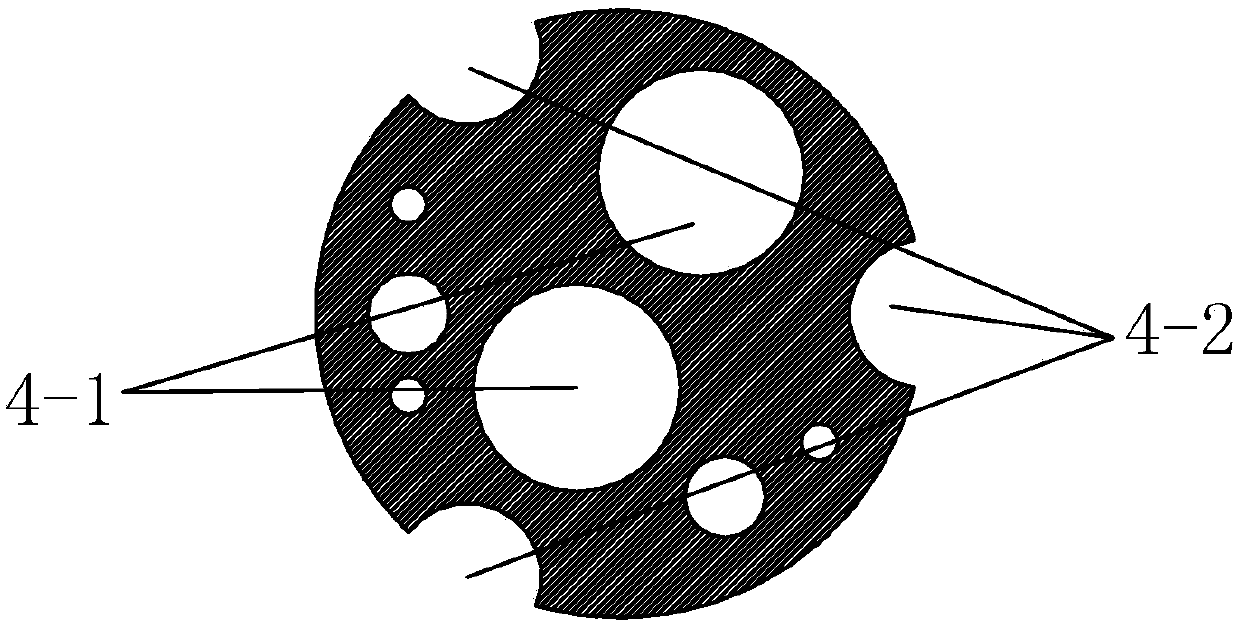

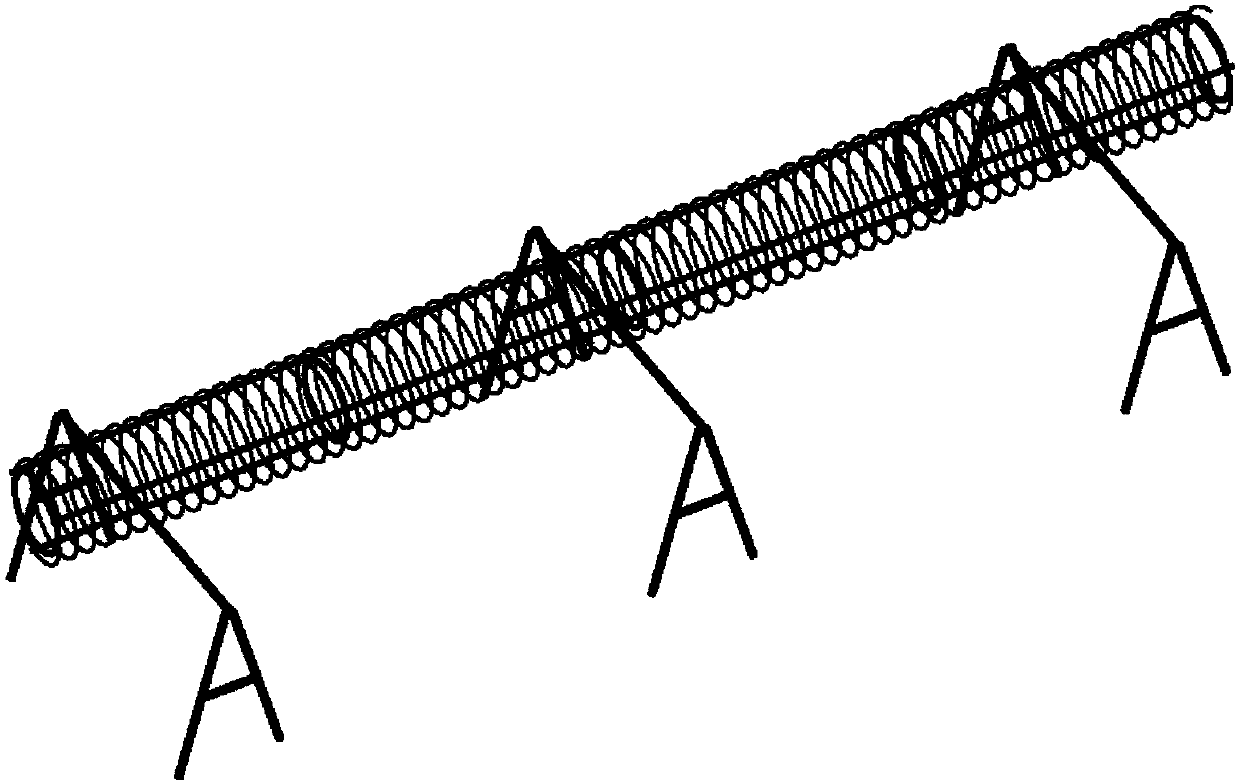

Structure and method used for improving compressive strength of pressure type anchor cable cement grouting body

A technology of compressive strength and cement grouting, which is applied in basic structure engineering, construction, sheet pile walls, etc., and can solve problems such as small volume shrinkage, pressure-type anchor cable restrictions, and pressure-type anchor cable theory imperfections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] Embodiment: The present invention is specifically implemented for the reinforcement of a certain project foundation pit. The project overview: the site is located in Guandu District, Kunming City, and the planned total land area of the proposed project is 52020.60m 2 The perimeter of the vertical excavation line of the foundation pit is about 849m. There are one-story basement section and two-story basement section. The excavation depth of the foundation pit is 3.6-7.7m. The supporting scheme adopted is: (1) grading + long auger bored pile + recyclable prestressed anchor cable scheme; (2) grading + grouting floral tube scheme.

[0067] The support plan (1) is adopted on the east side of the foundation pit. According to the geological survey report, the depth of the foundation pit is 7.7m, and the miscellaneous fill is deep, and the anchor cables will pass through the miscellaneous fill, peaty soil, clay, silt and other soil layers , and about 20 meters outside the mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com