A method for enriching high-quality lignin from lignocellulosic hydrolysis residue

A technology for lignocellulose and lignin, which is applied in the field of high-value utilization of lignin to achieve the effects of environmental friendliness, less by-products and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

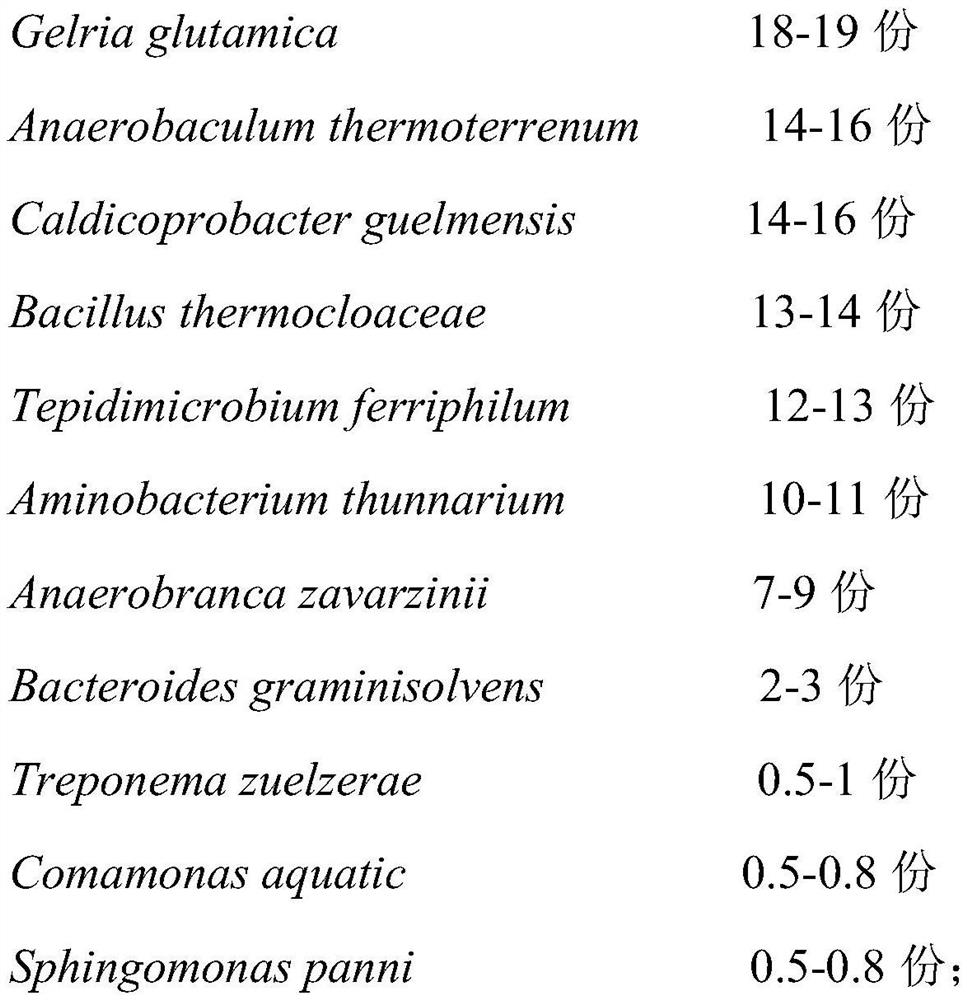

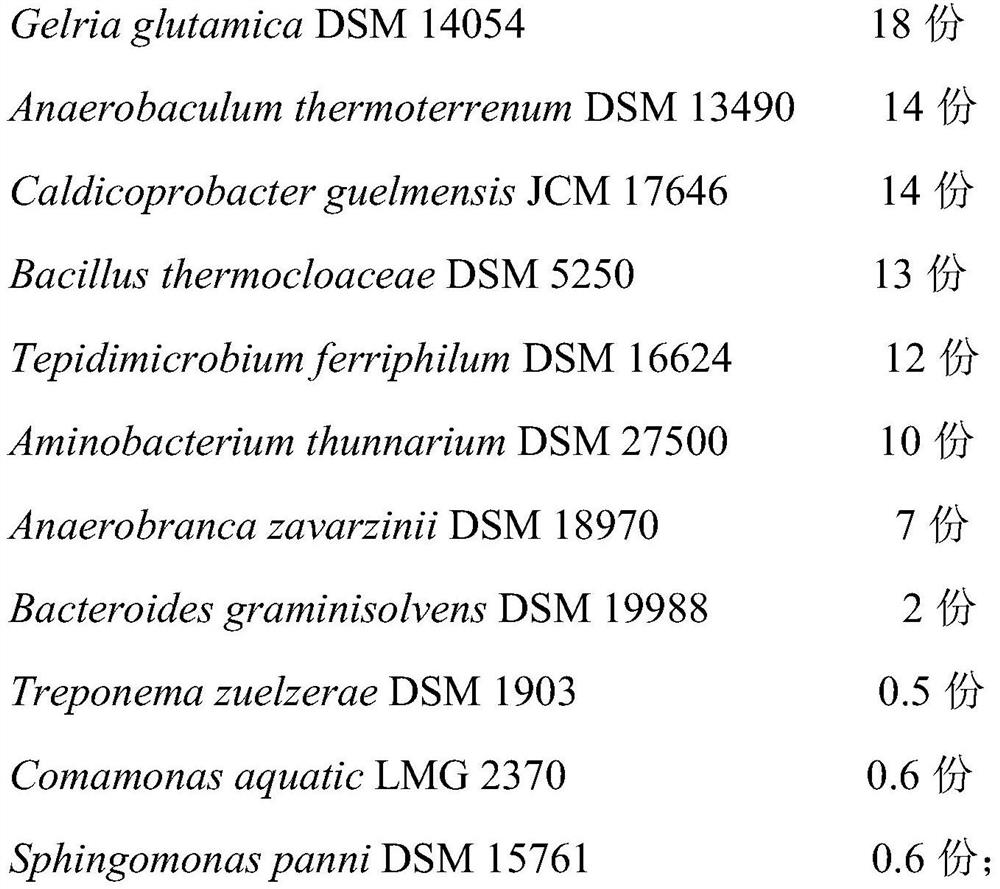

[0038] (1) Prepare the inoculum: take the sterilized sludge as the matrix (the mass fraction of its TS (total solids) is 0.86%, the mass fraction of VS (volatile solids) is 0.52%, VS / TS=60.4%), to The bacteria agent containing the following bacteria is added to the sterilized sludge, counted according to the number of bacteria:

[0039]

[0040] After the inoculum was prepared, the inoculum was cultured at 40°C until no gas was produced, and then inoculated in the hydrolyzed residue of corn stalks; the inoculation ratio of the inoculum to the hydrolyzed residue of corn stalks was 1.5:1 by weight;

[0041] (2) After inoculation, adjust the pH value of the system to 7.0, then seal it and introduce nitrogen to discharge the air, and then carry out anaerobic digestion treatment in an anaerobic environment. The temperature of anaerobic digestion is 35 ° C, and the time for 40 days.

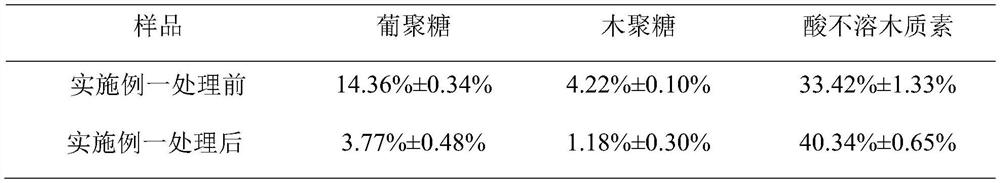

[0042] The corn stalk hydrolysis residue before and after the treatment of Example 1 is subject...

Embodiment 2

[0047](1) Prepare the inoculum: take the sterilized sludge as the matrix (the mass fraction of its TS (total solids) is 0.86%, the mass fraction of VS (volatile solids) is 0.52%, VS / TS=60.4%), to The bacteria agent containing the following bacteria is added to the sterilized sludge, counted according to the number of bacteria:

[0048]

[0049]

[0050] After preparing the inoculum, culture the inoculum at 40°C until no gas is produced, and then inoculate it in the hydrolyzed residue of corn stalks; the inoculation ratio of the inoculum to the hydrolyzed residue of corn stalk is 1:1 by weight;

[0051] (2) After inoculation, adjust the pH value of the system to 8.0, then seal it and introduce nitrogen gas to discharge the air, and then carry out anaerobic digestion treatment in an anaerobic environment. The temperature of anaerobic digestion is 55 ° C, and the time for 30 days.

[0052] The corn stalk hydrolysis residue before and after the treatment of Example 2 was su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com