Method for moving an elevator car to landing floor in case of event related to main electrical power supply of the elevator

A technology for elevator car and main power supply, applied in the field of elevators, can solve problems such as passenger discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

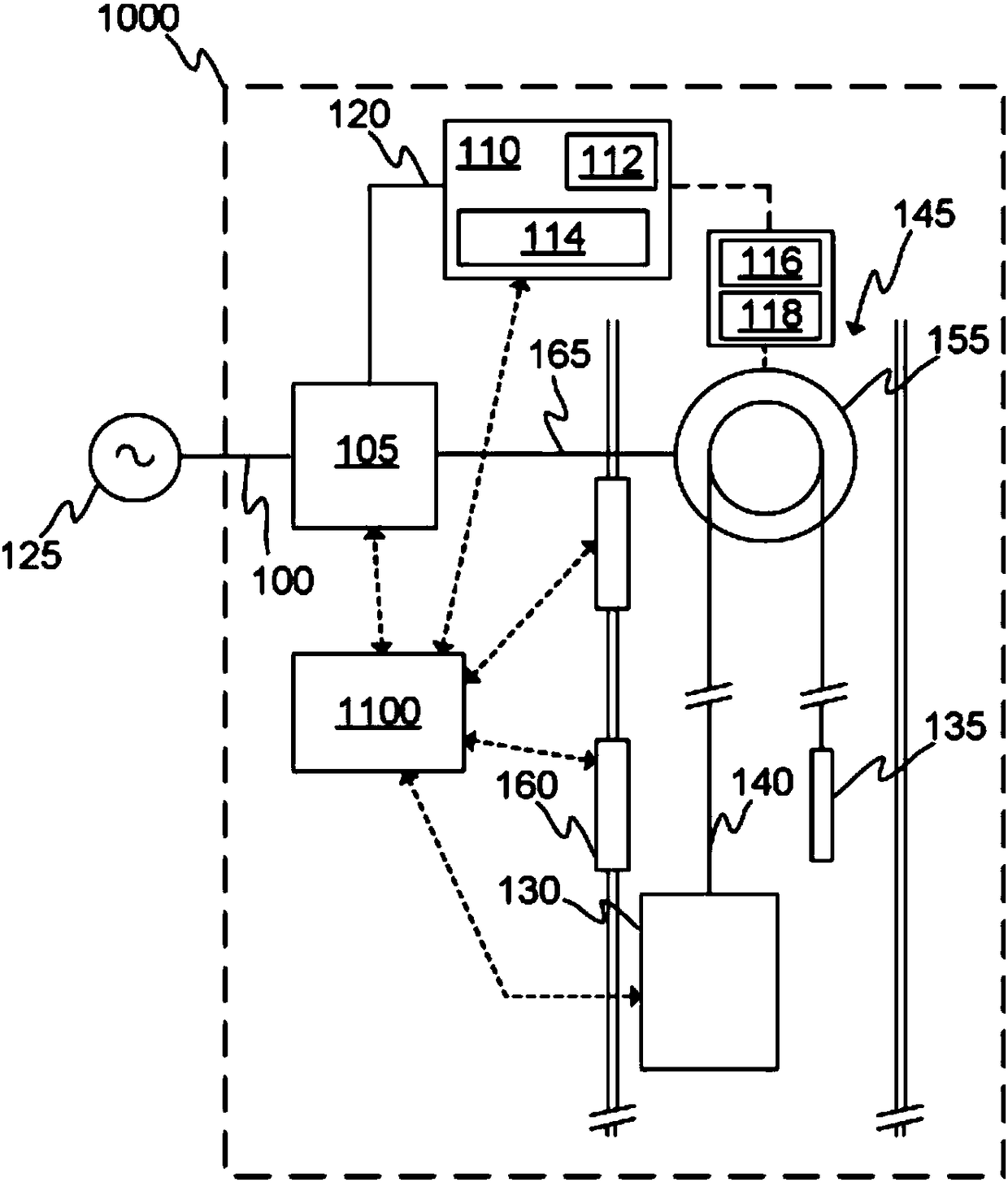

[0040] figure 1An elevator 1000 according to an embodiment of the invention is shown schematically. The elevator 1000 may include an electric motor 155 for moving the elevator car 130 included in the elevator 1000 . Elevator car 130 may be mechanically coupled to motor 155, for example by hoist ropes 140, hydraulic means, or in the case of a linear motor in a more direct manner. The operation of the electric motor 155 may be controlled by an electric drive 105 such as a frequency converter or inverter.

[0041] Lifting rope 140 may comprise, for example, steel or carbon fiber. The term "hoisting rope" does not in any way limit the form of the element. For example, hoisting ropes 140 may be implemented as ropes 140, belts, or tracks in a ropeless or ropeless elevator.

[0042] The elevator 1000 may include an elevator control unit 1100 for controlling the operation of the elevator 1000 . The elevator control unit 1100 may be a separate device, or may be included in other c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com