Brake friction force power generating system on electric vehicle

A technology of electric vehicles and power generation systems, applied in electric vehicles, electric components, motors, etc., can solve problems such as tire wear and shortened tire service life, and achieve the effect of large braking force and large power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

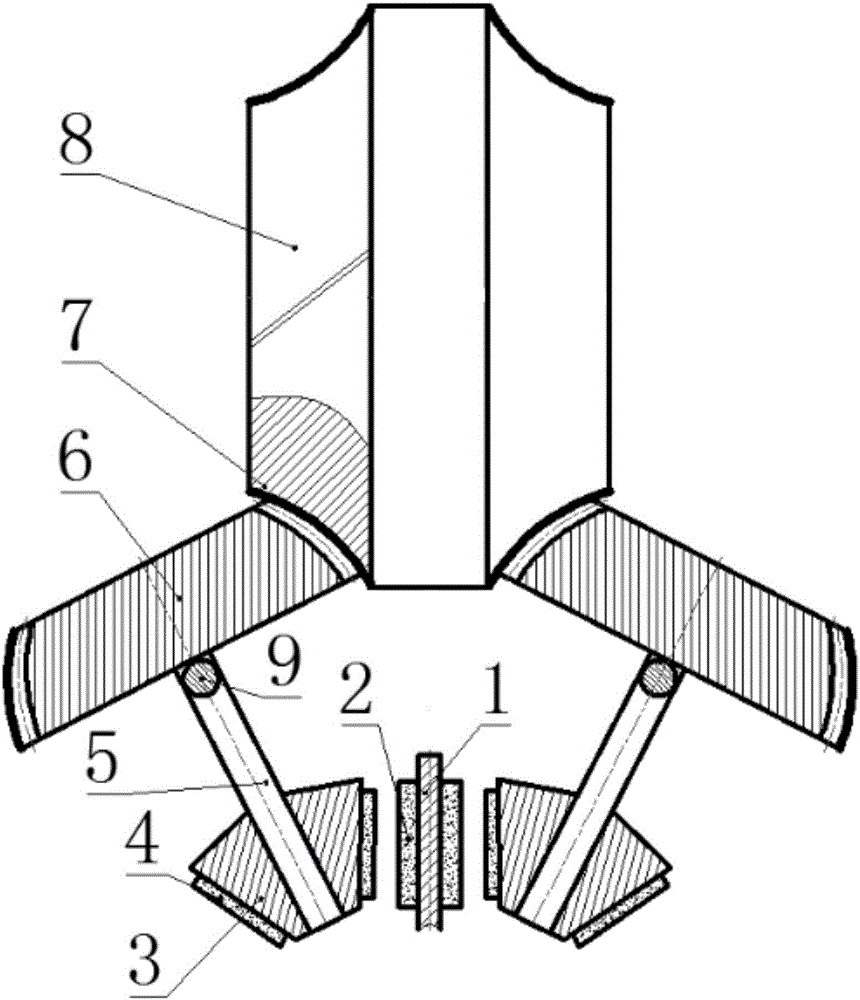

[0020] Such as figure 1 The brake friction power generation system on the electric vehicle shown includes a brake disc 1 that rotates with the wheel and a brake pad 2 fixed on the brake disc. Two conical pads are placed symmetrically on both sides of the brake disc plane. There is a gap between the wheel 3, the idler wheel 3 and the brake pad 2 in the non-braking state. In the braking state, the two idler wheels are in close contact with the brake pad 2 to generate friction; the two idler wheels are respectively connected by The shaft 5 is connected to the toothed cone 6, and the toothed toothed cone 6 meshes with the generator rotor 8. The left and right two toothed toothed cones and the two meshing surfaces 7 of the generator rotor 8 exist; , when force is applied to the left and right sides of the rollers, so that the two rollers contact the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com