High-fatigue-resistance composite material automobile plate spring and manufacturing method thereof

A composite material and automobile plate technology, which is applied in the field of high fatigue-resistant composite material automobile leaf spring and its production, can solve the problems of inability to achieve the strength between high-rise layers, not meeting industrialization requirements, and cumbersome preform process. Excellent shearing, high stiffness and light weight results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

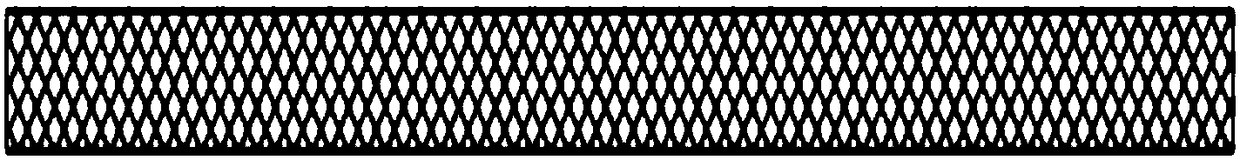

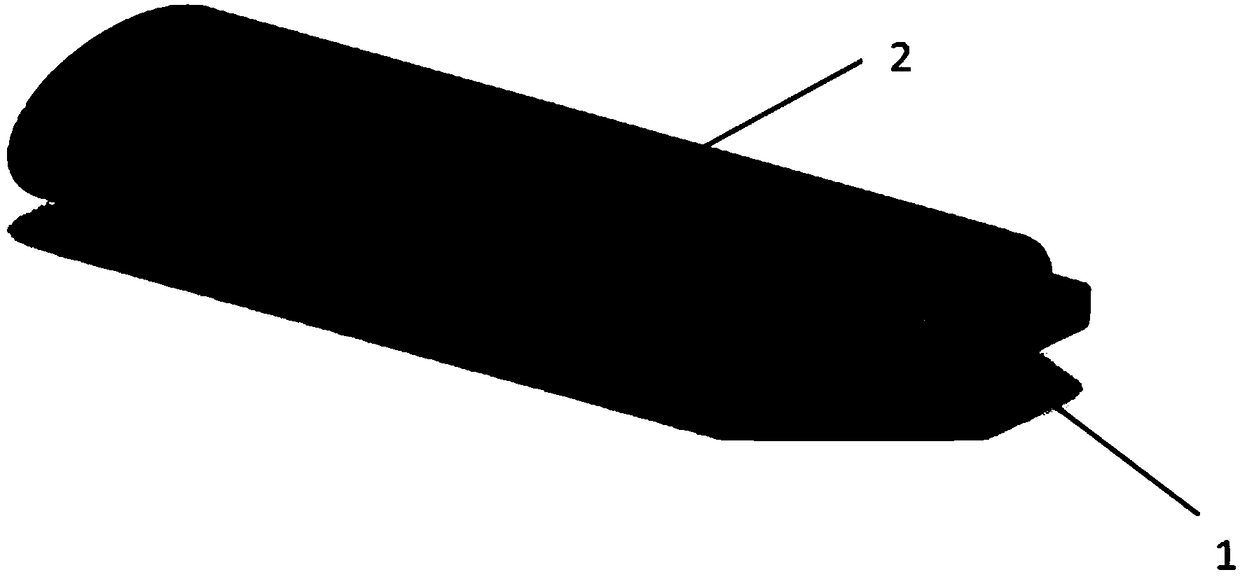

[0030] Such as Figure 4 As shown, it is a kind of high fatigue resistance composite automobile leaf spring provided by the present invention. At least one layer of two-dimensional braided sleeve on the outer surface.

[0031] Such as Figure 1 to Figure 3 Shown, the present invention also provides the manufacture method of this high fatigue resistance composite material automobile leaf spring, comprises the following steps:

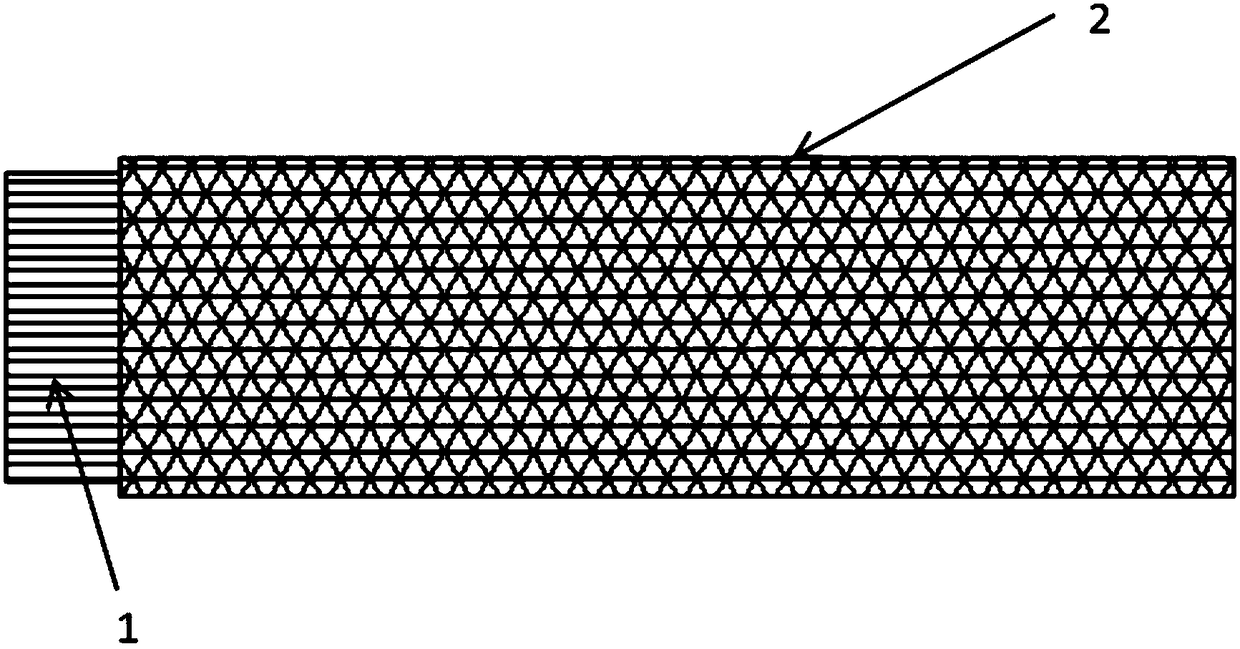

[0032] Laying the at least one unidirectional fiber layer 1 in layers;

[0033] The at least one layer of two-dimensional braided sleeve 2 is covered with the at least one layer of unidirectional fiber layer 1 to prepare a fiber preform (such as figure 2 and image 3 shown), the number of unidirectional fiber layers and the number of two-dimensional braided sleeve layers can be adjusted according to the required stiffness, strength and product thickness to prepare a fiber preform;

[0034] The fiber preform is put into the forming mold, impregnated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com