Automotive Antenna Injection Mold and Injection Mold

A technology for injection molds and automobile antennas, which is applied in the field of mold manufacturing, can solve the problems of increasing the production defect rate, difficult to take out the molded products, damage the molded products, etc., and achieves the effects of increasing the difficulty of taking out, increasing the production cost, and wasting production resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

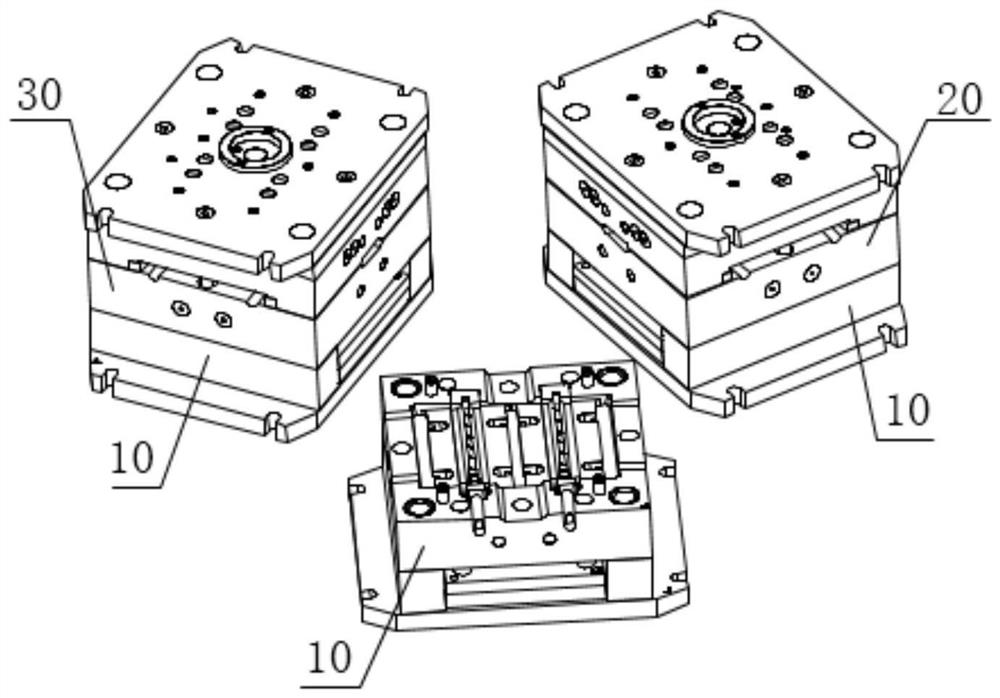

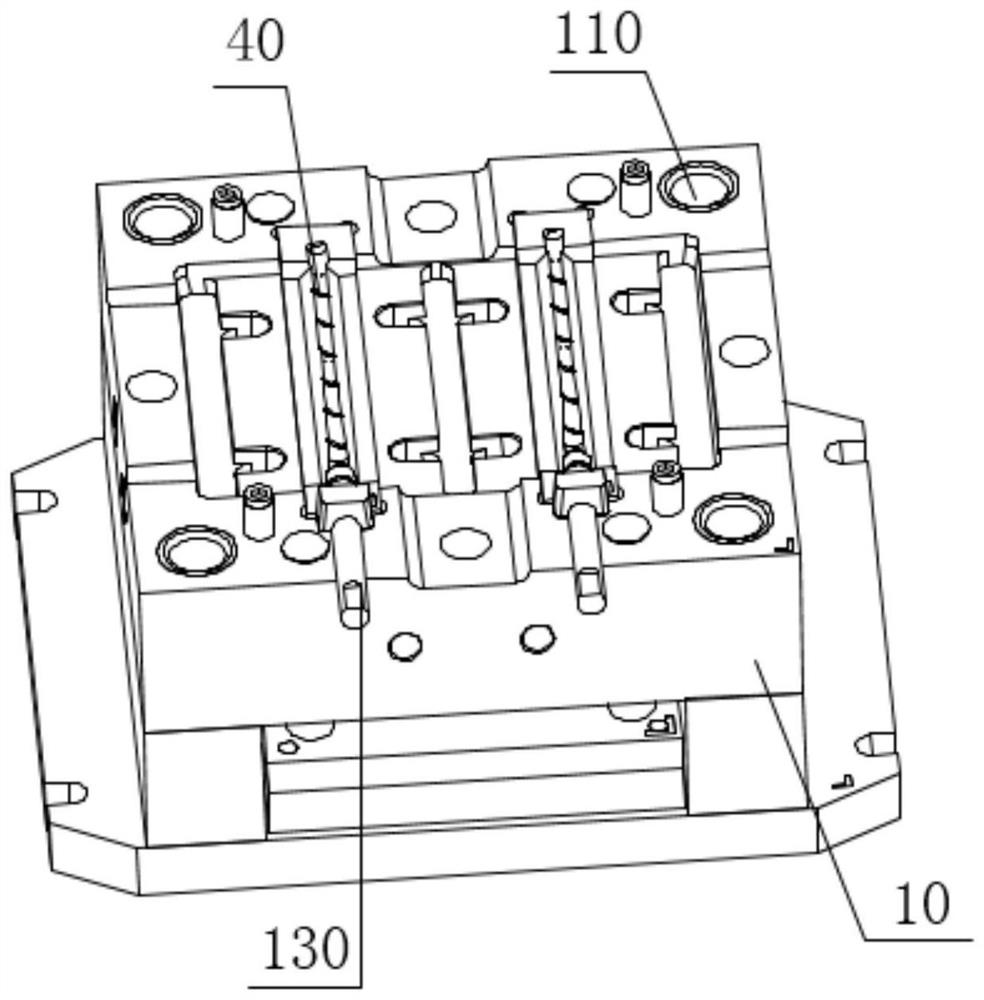

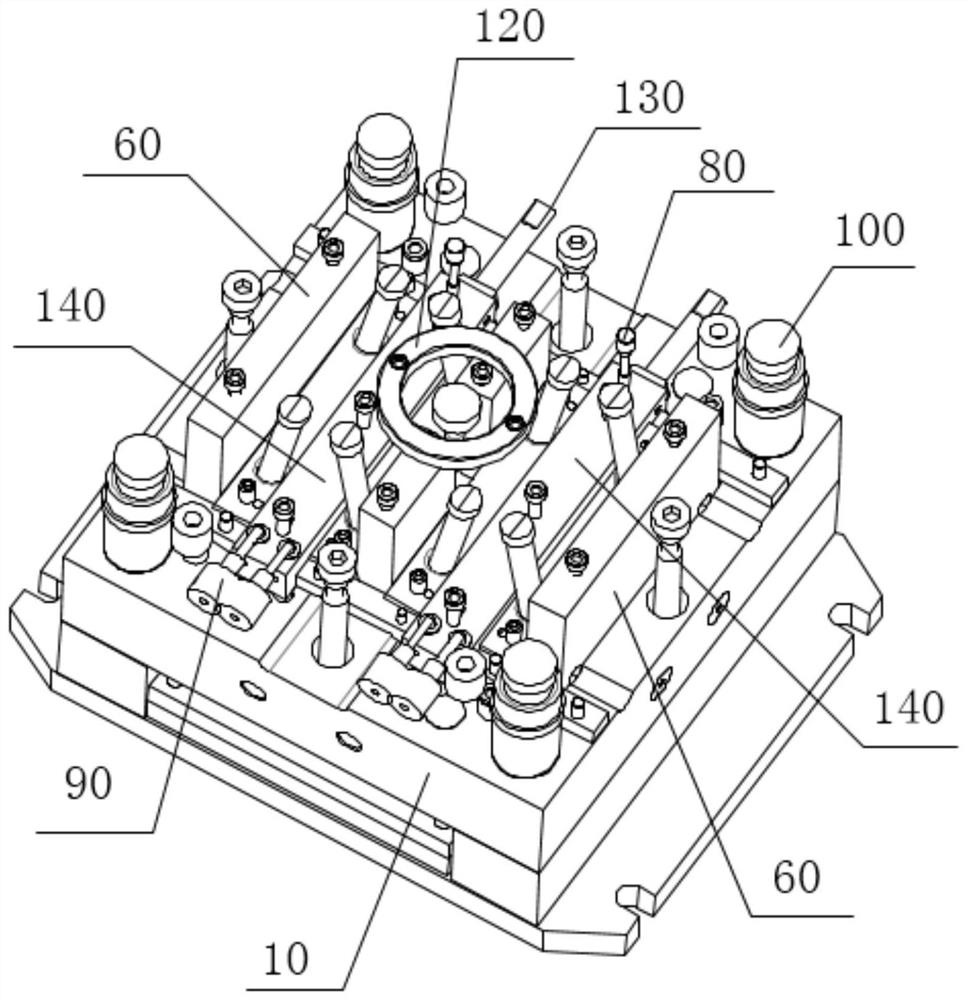

[0047] like Figure 1-9 As shown, the automotive antenna injection mold provided in this embodiment includes a front mold 10 and a plurality of rear molds; the plurality of rear molds are compressed and closed with the front mold 10 in sequence to form a plurality of different cavities, and a plurality of different mold cavities are formed. The cavities can be injected separately to form antennas of different shapes.

[0048] Specifically, the automotive antenna injection mold includes a front mold 10 and a plurality of rear molds, and each rear mold can be compressed and closed with the front mold 10 to form different cavities, and different cavities can be used to mold different shapes of antennas.

[0049] Among them, a plurality of rear molds should be pressed and closed with the front mold 10 in sequence, for example, the previous back mold and the front mold 10 are pressed and closed to form a smooth cavity structure. An antenna with a smooth surface can be obtained by ...

Embodiment 2

[0082] This embodiment also provides an injection mold, including the above-mentioned automobile antenna injection mold.

[0083] Specifically, the injection mold can be molded twice to form an injection molded product, which solves the problem that it is difficult to release the mold or even damage the molded product due to structural problems on the product that needs to be injected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com