Manipulator for assembly

A technology of manipulators and suction cups, applied in the direction of manipulators, program-controlled manipulators, chucks, etc., can solve problems such as the inconvenience of rivet processing, and achieve the effects of improving processing efficiency, facilitating passage, and increasing intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

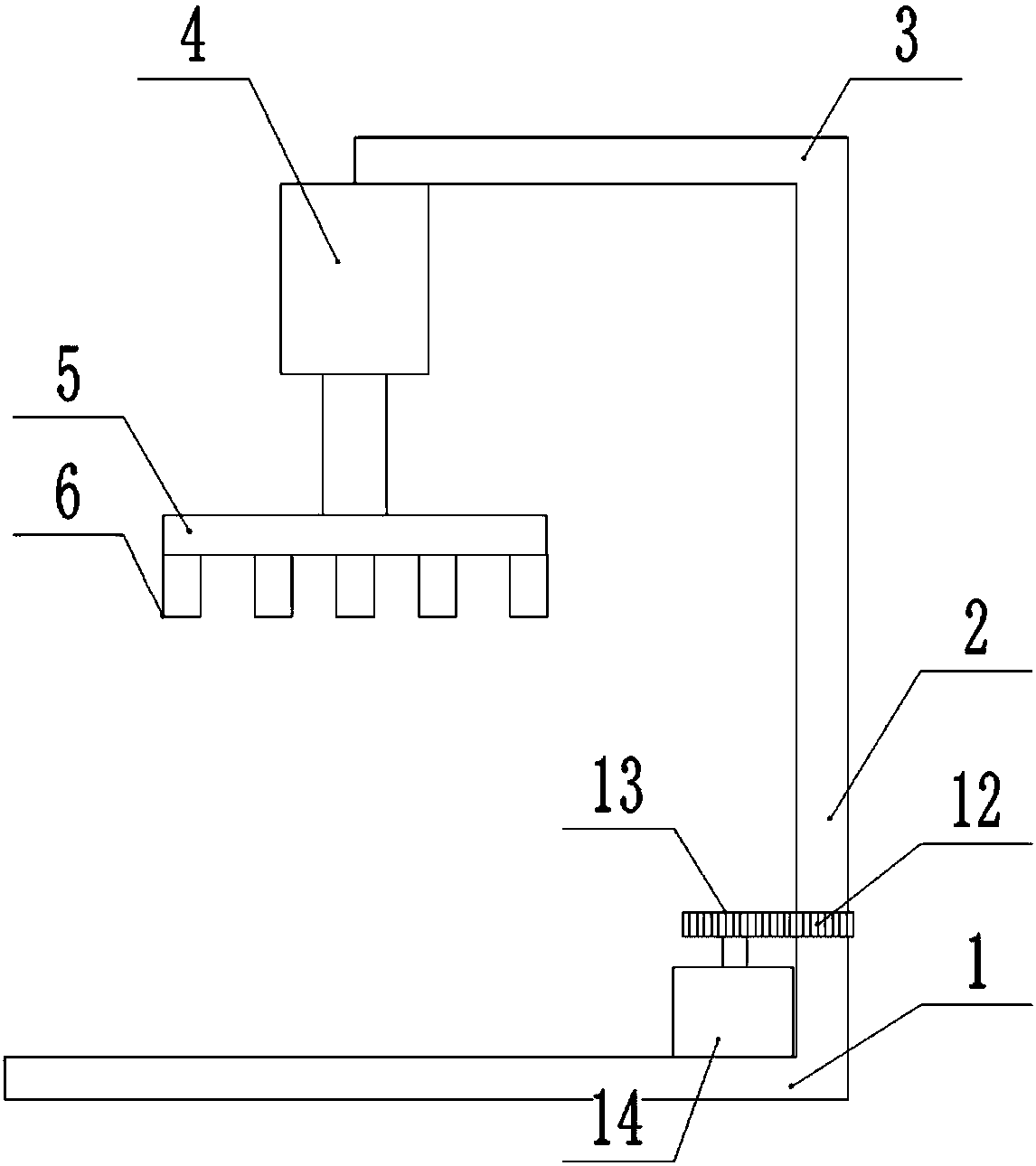

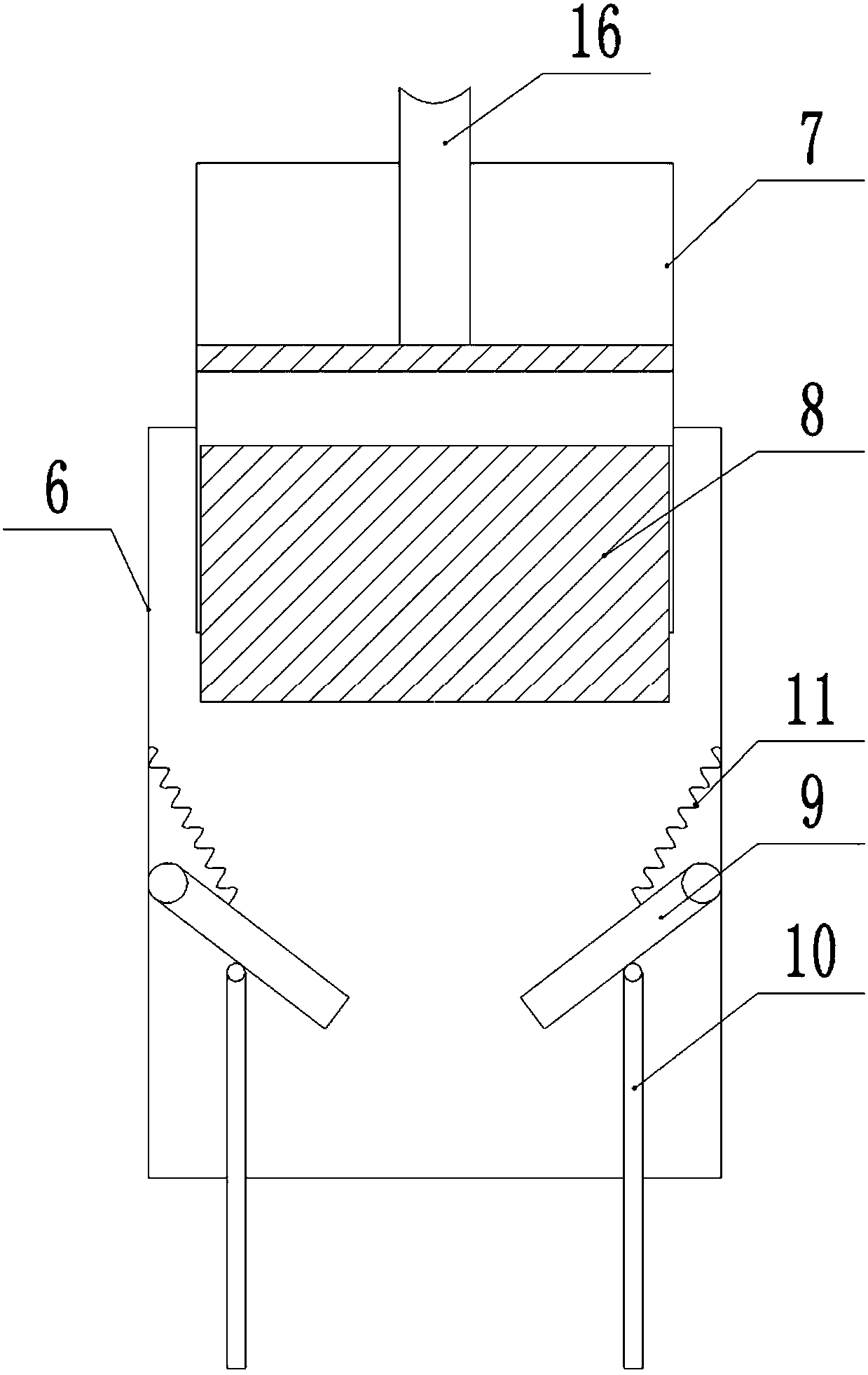

[0020] Such as figure 1 As shown, a manipulator for assembly includes a base 1, a bearing seat is installed on the right end of the base 1 through bolts, an interference-fit bearing is installed in the bearing seat, a support column 2 is installed in the bearing, and a toothed disc 12 is installed in the support. A servo motor 14 is installed on the base 1 at the right end of the support column 2, and a gear 13 is installed at the upper end of the rotating shaft of the servo motor 14. Rotate in the bearing seat; the top of the support column 2 is equipped with a cross bar 3, the left end of the cross bar 3 is connected with the first cylinder 4 with the piston rod downward through the bolt, and the lower end of the first piston rod of the first cylinder 4 is fixed with the bolt. Plate 5, the lower end of fixed plate 5 is equipped with a plurality of cylindrical suction cups 6 by bolts, preferably 25 in the present embodiment; figure 2 As shown, the upper end of the inner wal...

Embodiment 2

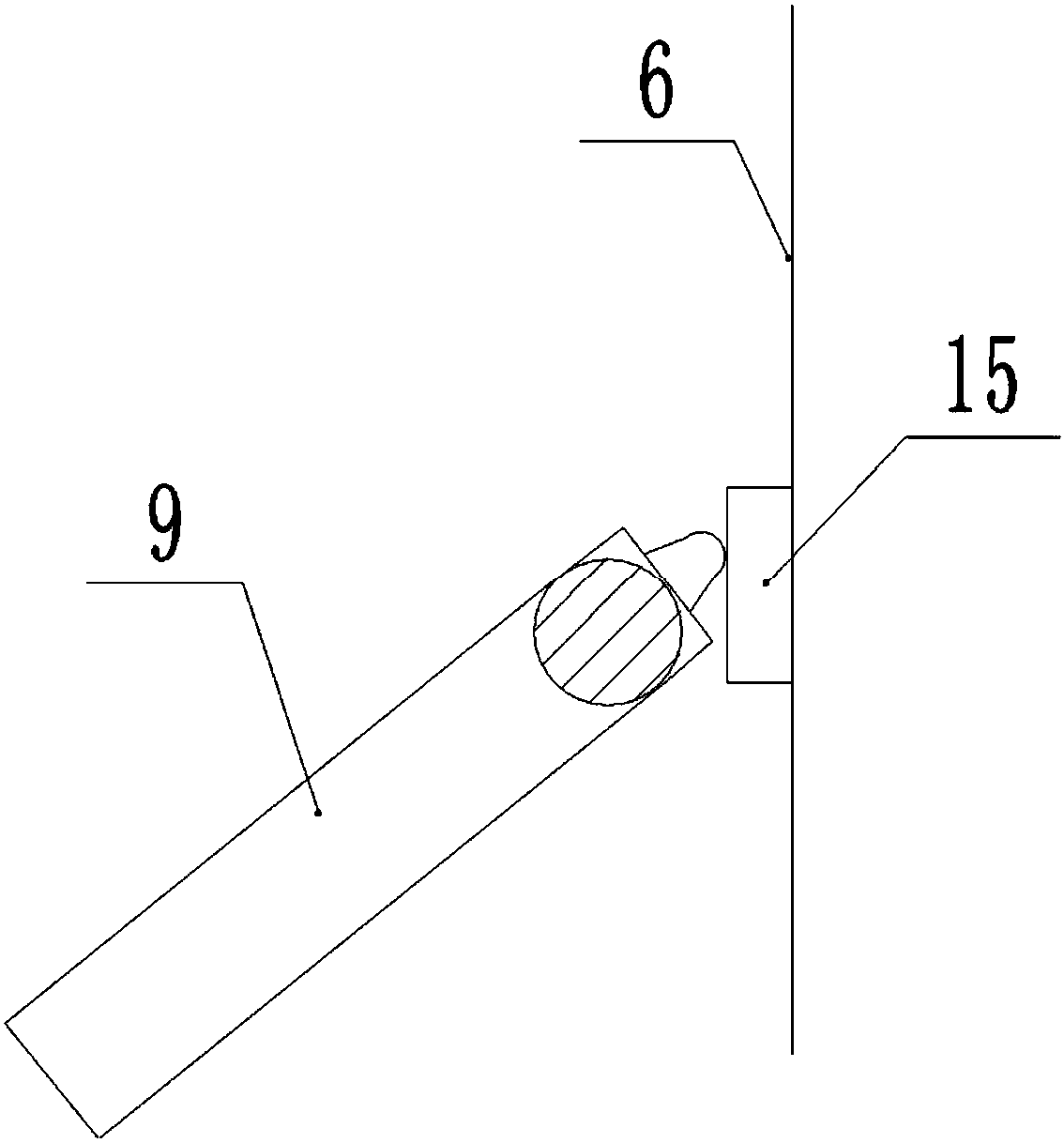

[0023] Such as image 3 As shown, on the basis of Embodiment 1, a self-locking switch 15 is installed at the joint between the baffle plate 9 and the inner wall of the suction cup 6, and the self-locking switch 15 is connected to the electromagnet 8 through a wire. When closed, the support rod 10 rotates to push the baffle plate 9 to rotate, and the baffle plate 9 rotates upwards to push the self-locking switch 15 to close to attract the rivet; when the rivet needs to be placed, the second cylinder 7 pushes the electromagnet 8 to move downward, and the electromagnet 8 Push baffle plate 9 to rotate downwards, and when baffle plate 9 rotates downwards, promote self-locking switch 15, the circuit of electromagnet 8 is disconnected, and rivet breaks away from electromagnet 8 after electromagnet 8 power-off, is placed on the installation place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com