A processing fixture and processing method for drilling holes on the surface of a conical bush

A processing method and cone technology, which is applied in the direction of manufacturing tools, metal processing equipment, drilling/drilling equipment, etc., can solve the problems of machining accuracy, workpiece clamping, positioning difficulties, and workpiece clamping operations that affect the cone-shaped bushing parts Complicated problems, to achieve the effect of ensuring processing consistency, low manufacturing cost, and saving loading and unloading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

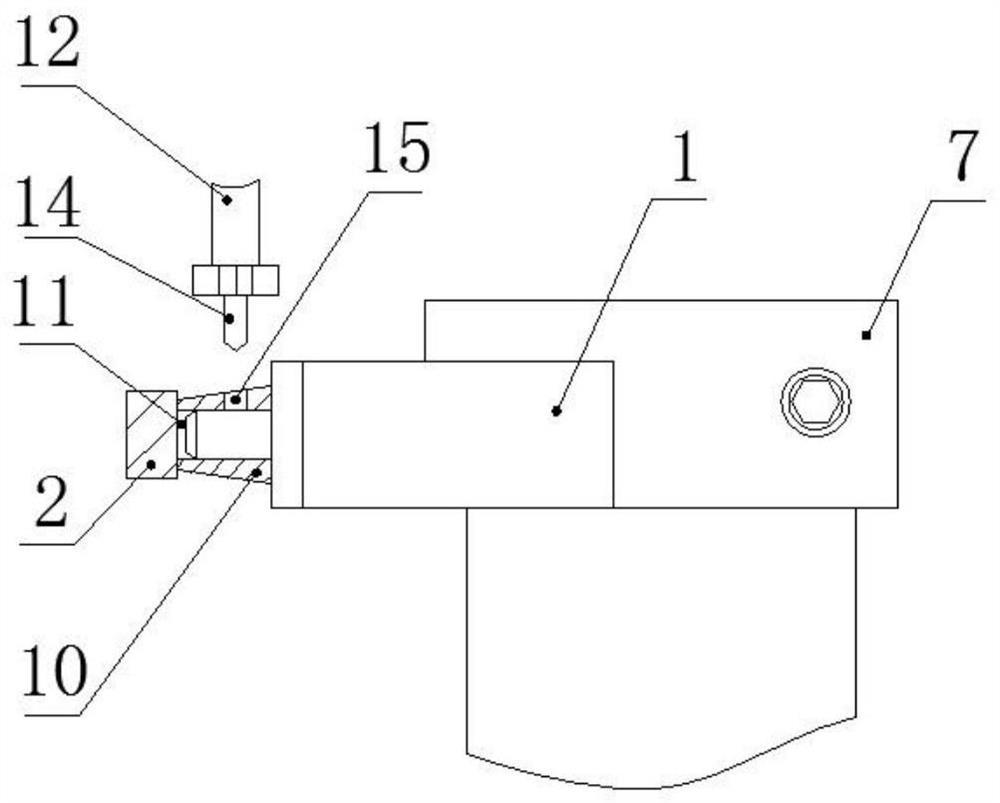

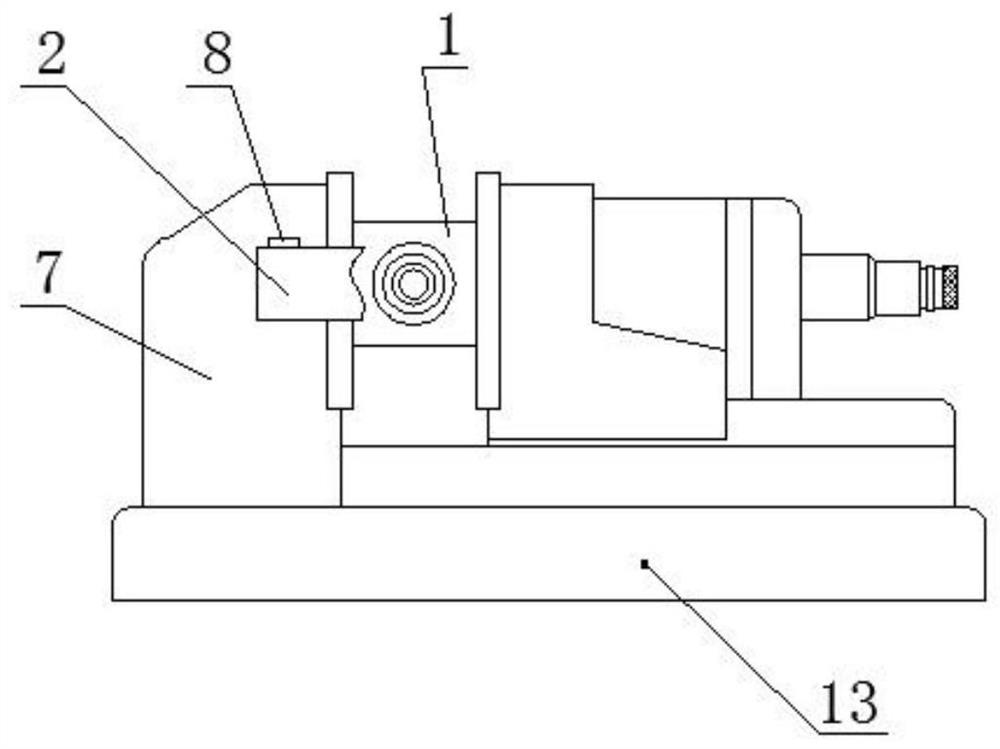

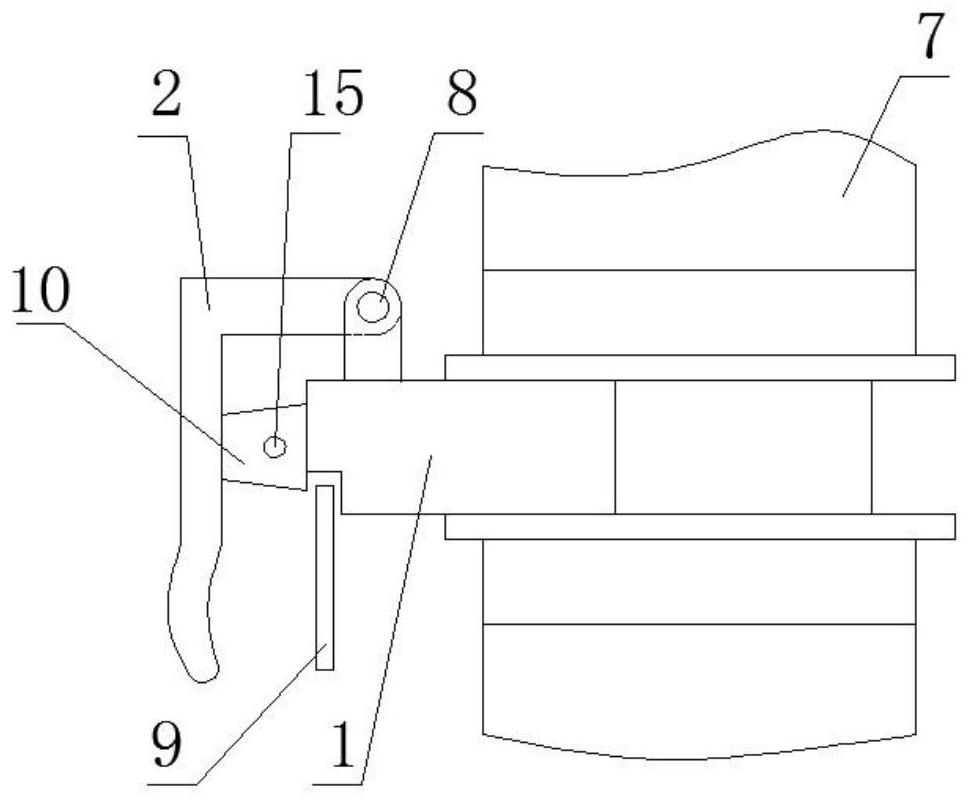

[0033] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

[0034] The invention provides a processing fixture and processing method for drilling holes on the surface of a conical bush, such as Figure 1 to Figure 6 As shown, the processing fixture includes a clamp body 1 and a handle 2. One end of the clamp body 1 is a fixed end 3, and the other end of the clamp body 1 is a processing end 4. The fixed end 3 is fixedly connected with the machine tool table 13, and the end surface of the processing end 4 Boss 5 is provided, hinge seat 6 is provided on the outside of processing end 4, one end of handle 2 is connected with hinge seat 6 in rotation, and the other end of handle 2 is movably covered on the end surface of boss 5 .

[0035] Adopting the technical solution provided by the invention, when drilling holes on the outer surface of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com