Wormwood-based biomass charcoal, and preparation method and application thereof

A technology of biomass charcoal and wormwood, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as harm to the human body and the natural environment, difficult microbial degradation, etc., to achieve low cost, and the adsorption process can be The effect of short control and preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

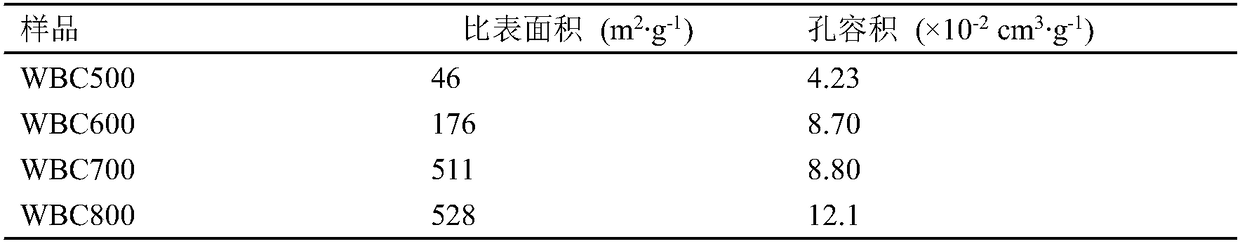

Image

Examples

Embodiment 1

[0026] The present embodiment is the preparation method of wormwood-based biochar, comprising the following steps:

[0027] Step 1, putting 200g of raw material wormwood residue into a drying oven and drying at 50°C to obtain wormwood residue powder;

[0028] Step 2, placing the wormwood slag powder in a muffle furnace, raising the temperature to 500°C at a heating rate of 10°C / min, then carbonizing at a constant temperature for 3 hours, and obtaining carbonized wormwood slag powder after cooling down to normal temperature;

[0029] Step 3: Pickling the carbonized wormwood residue powder with aqueous hydrochloric acid solution with a concentration of 1 mol / L for 2 hours, then washing with deionized water until the pH is neutral, and finally drying and sieving through 100 mesh to obtain wormwood-based biochar .

[0030] The application of the wormwood-based biochar obtained in step 3 in removing tetracycline hydrochloride in water comprises the following steps:

[0031] Step ...

Embodiment 2

[0035] The present embodiment is the preparation method of wormwood-based biochar, comprising the following steps:

[0036] Step 1, putting 200g of raw material wormwood residue into a drying oven and drying at 65°C to obtain wormwood residue powder;

[0037] Step 2, placing the wormwood slag powder in a muffle furnace, raising the temperature to 600°C at a heating rate of 10°C / min, then carbonizing at a constant temperature for 3 hours, and obtaining carbonized wormwood slag powder after cooling down to normal temperature;

[0038] Step 3: Pickling the carbonized wormwood residue powder with aqueous hydrochloric acid solution with a concentration of 1 mol / L for 2 hours, then washing with deionized water until the pH is neutral, and finally drying and sieving through 100 mesh to obtain wormwood-based biomass carbon.

[0039] The application of the wormwood-based biochar obtained in step 3 in removing tetracycline hydrochloride in water comprises the following steps:

[0040]...

Embodiment 3

[0044] The present embodiment is the preparation method of wormwood-based biochar, comprising the following steps:

[0045] Step 1, putting 200g of raw material wormwood residue into a drying oven and drying at 65°C to obtain wormwood residue powder;

[0046] Step 2, placing the wormwood slag powder in a muffle furnace, raising the temperature to 700°C at a heating rate of 10°C / min, then carbonizing at a constant temperature for 3 hours, and obtaining carbonized wormwood slag powder after cooling down to normal temperature;

[0047] Step 3: Pickling the carbonized wormwood residue powder with aqueous hydrochloric acid solution with a concentration of 1 mol / L for 2 hours, then washing with deionized water until the pH is neutral, and finally drying and sieving through 100 mesh to obtain wormwood-based biomass carbon.

[0048] The application of the wormwood-based biochar obtained in step 3 in removing tetracycline hydrochloride in water comprises the following steps:

[0049]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com