Environment-friendly filtering material

A filter material and vinylon technology, applied in the field of environmentally friendly filter materials, can solve the problems of environmental air pollution, public nuisance, and unfavorable environmental protection, and achieve the effects of good water resistance, high wet strength, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

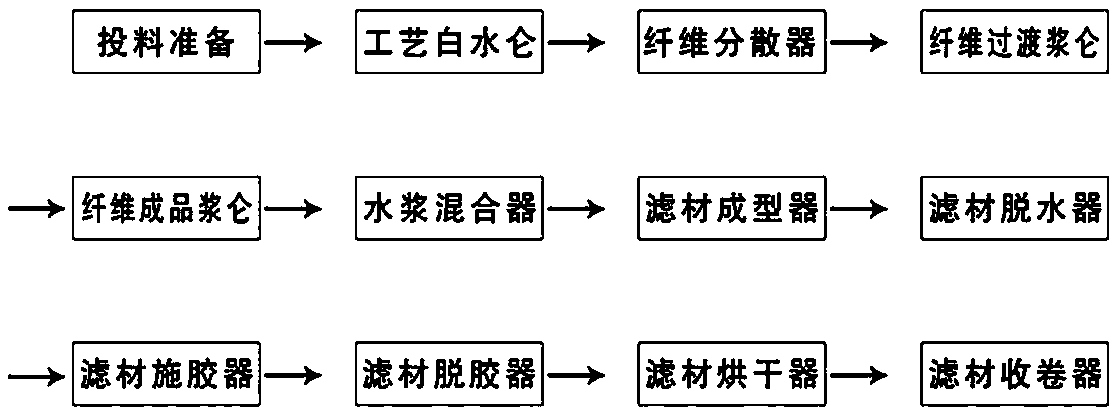

Image

Examples

Embodiment 1

[0011] The formula of the environment-friendly filter material is as follows:

[0012] Coniferous wood pulp 5.5kg, vinylon superfine fiber 1kg, vinylon insoluble fiber 1kg, vinylon water-soluble fiber 1kg, vinylon high-strength fiber 1kg.

[0013] Its production steps:

[0014] 1. Feeding preparation: First, carefully check and identify, the name and quality of raw materials,

[0015] Strictly weigh and classify according to the proportion of ingredients; build a process white water tank underground with a water capacity of 40 tons to ensure the temperature of the water quality and the needs of the production process water, and the white water is recycled and replaced regularly. During the feeding preparation period, all the places that need water in each process part are in place to meet the needs of the production process.

[0016] 2, fiber dispersion: take by weighing coniferous wood pulp by above-mentioned formula weight, drop into fiber dispersion

[0017] After starti...

Embodiment 2

[0027] The formula of the environment-friendly filter material is as follows:

[0028] Coniferous wood pulp 6kg, vinylon superfine fiber 1.5kg, vinylon insoluble fiber 1.5kg, vinylon water-soluble fiber 1.5kg, vinylon high-strength fiber 1.5kg.

[0029] Others are the same as in Example 1

Embodiment 3

[0031] The formula of the environment-friendly filter material is as follows:

[0032] Coniferous wood pulp 7kg, vinylon superfine fiber 1.8kg, vinylon insoluble fiber 1.8kg, vinylon water-soluble fiber 1.8kg, vinylon high-strength fiber 1.8kg.

[0033] Others are the same as in Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com