Medical ultrasonic probe disinfecting cabin

A technology of ultrasonic probe and disinfection chamber, which is applied in the direction of disinfection, sanitary equipment for toilets, water supply equipment, etc., can solve the problems of reduced disinfection effect, limited area for disinfection and sterilization, and high cost, so as to achieve increased disinfection area, good disinfection effect, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

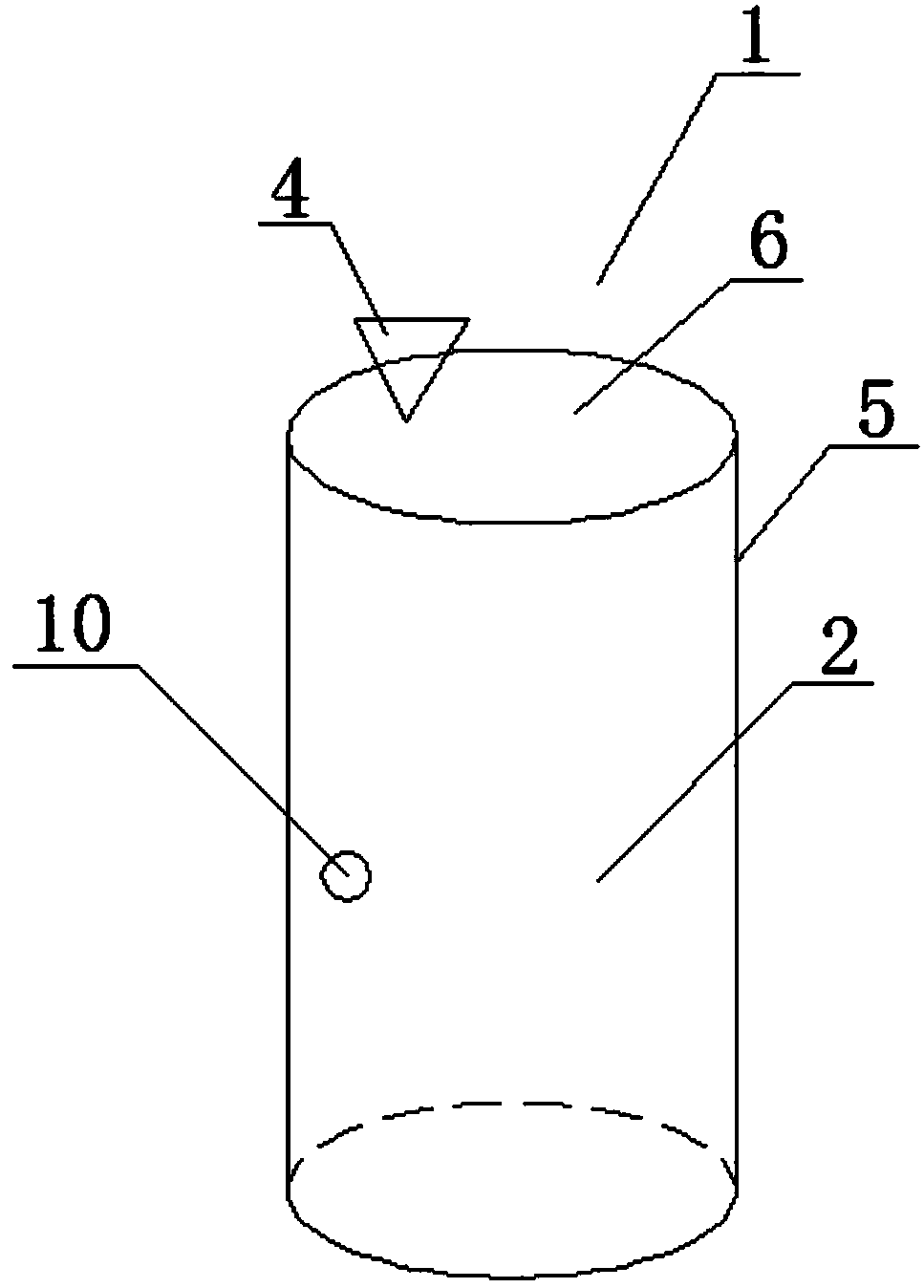

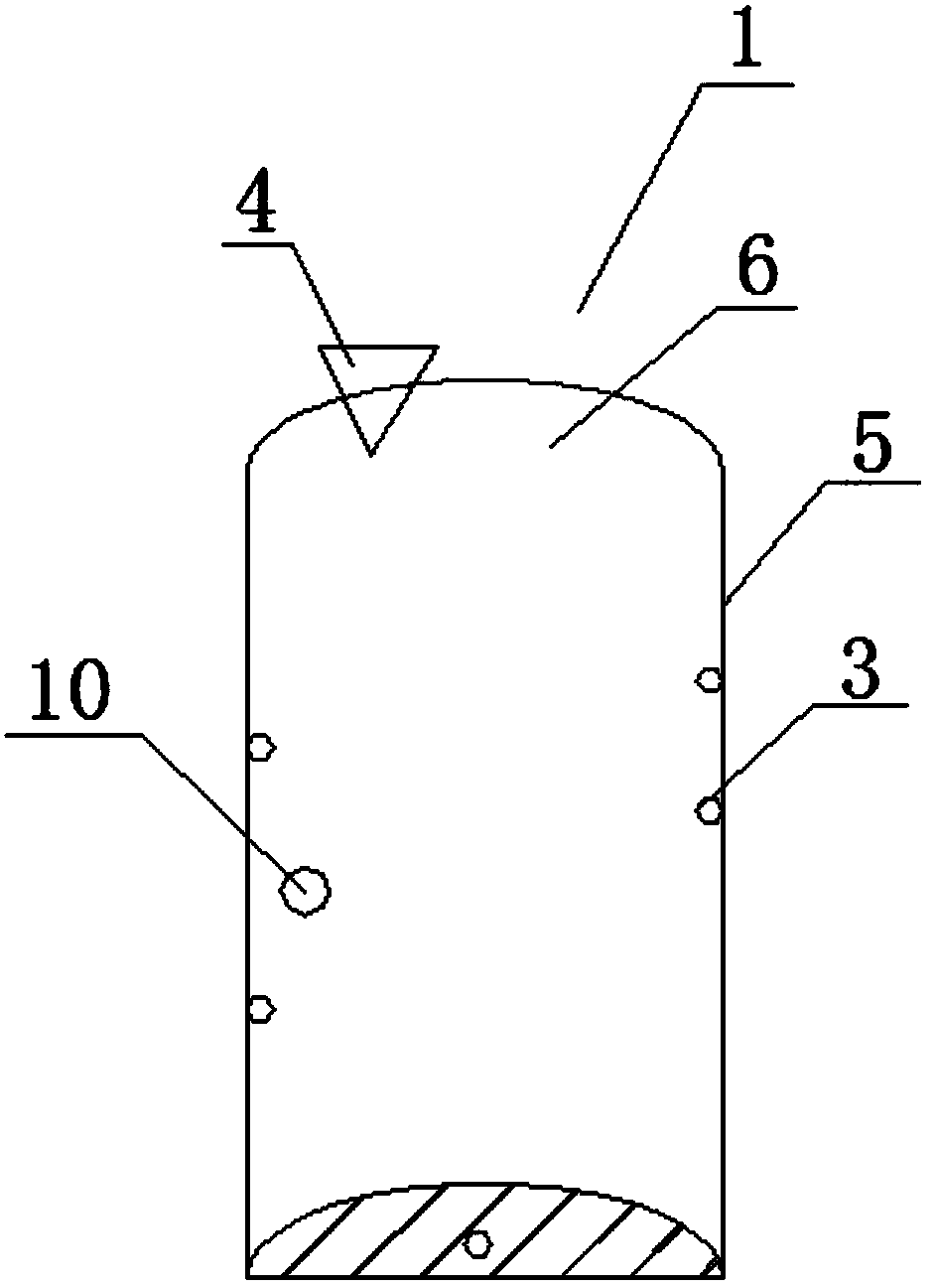

[0027] Such as figure 1 , figure 2 As shown, a medical ultrasonic probe sterilization warehouse 1 includes a hollow warehouse 2, a deep ultraviolet light source 3, and a probe holder 4. The hollow warehouse 2 is surrounded by a warehouse wall 5, and the warehouse wall 5 has a suitable In the opening 6 where the probe is inserted and removed, the internal size and shape of the hollow chamber 2 is suitable for accommodating the deep ultraviolet light source 3 and the probe. The deep ultraviolet light source 3 is installed inside the hollow chamber 2 and is capable of To realize the multi-point distribution of omni-directional disinfection without dead corners after the probe is inserted, the probe holder 4 is located near the opening 6 and connected to the warehouse wall 5, and the probe holder 4 is used to fix the probe in the warehouse Inside, the probe is placed in the irradiation area of the deep ultraviolet light generated by the deep ultraviolet light source 3, and the pr...

Embodiment 2

[0036] Such as figure 1 , figure 2 As shown, a medical ultrasonic probe sterilization warehouse 1 includes a hollow warehouse 2, a deep ultraviolet light source 3, and a probe holder 4. The hollow warehouse 2 is surrounded by a warehouse wall 5, and the warehouse wall 5 has a suitable In the opening 6 where the probe is inserted and removed, the internal size and shape of the hollow chamber 2 is suitable for accommodating the deep ultraviolet light source 3 and the probe. The deep ultraviolet light source 3 is installed inside the hollow chamber 2 and is capable of To realize the multi-point distribution of omni-directional disinfection without dead corners after the probe is inserted, the probe holder 4 is located near the opening 6 and connected to the warehouse wall 5, and the probe holder 4 is used to fix the probe in the warehouse Inside, the probe is placed in the irradiation area of the deep ultraviolet light generated by the deep ultraviolet light source 3, and the pr...

Embodiment 3

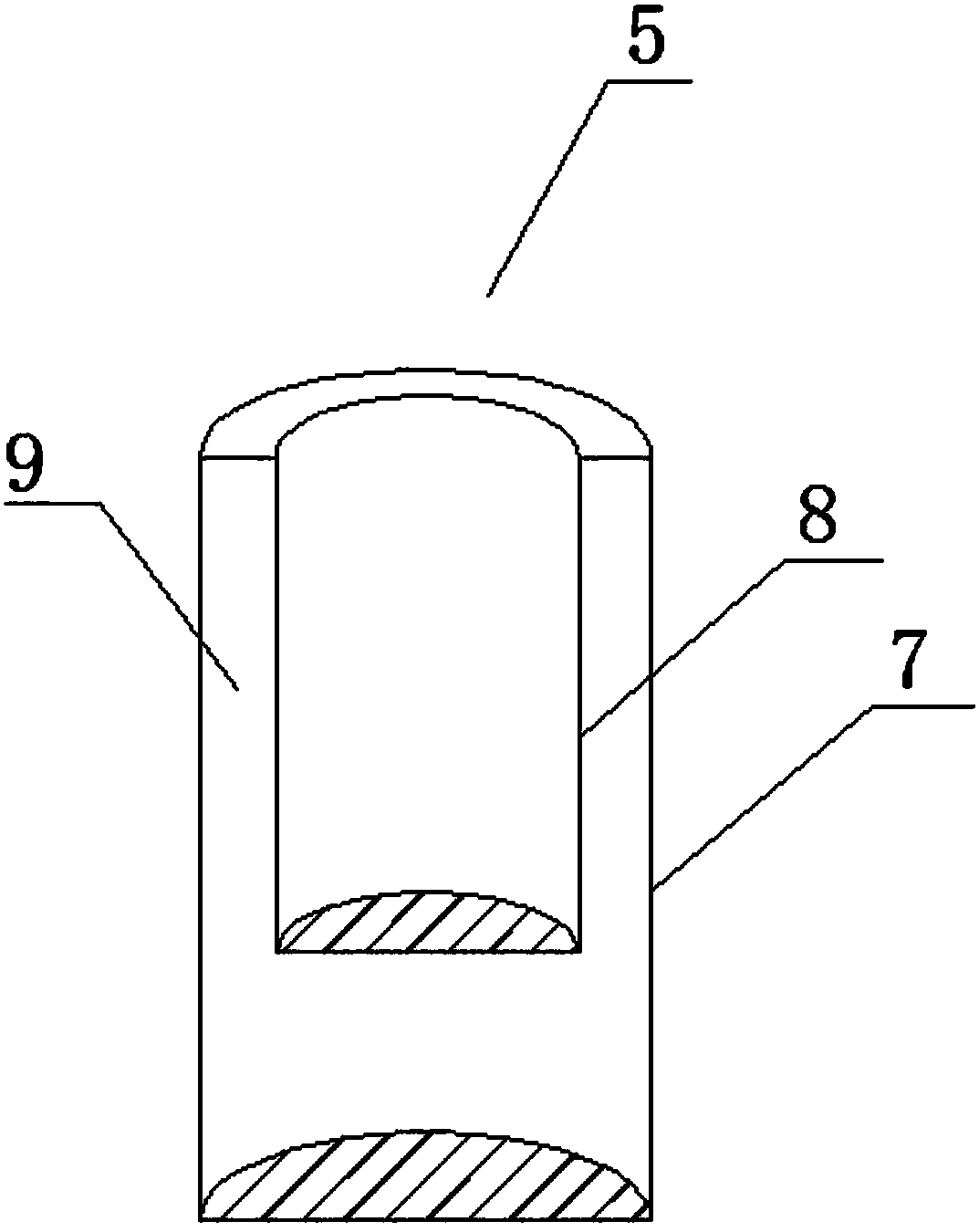

[0038] Such as figure 1 , figure 2 , image 3 As shown, a medical ultrasonic probe sterilization warehouse 1 includes a hollow warehouse 2, a deep ultraviolet light source 3, and a probe holder 4. The hollow warehouse 2 is surrounded by a warehouse wall 5, and the warehouse wall 5 has a suitable In the opening 6 where the probe is inserted and removed, the internal size and shape of the hollow chamber 2 is suitable for accommodating the deep ultraviolet light source 3 and the probe. The deep ultraviolet light source 3 is installed inside the hollow chamber 2 and is capable of To realize the multi-point distribution of omni-directional disinfection without dead ends after the probe is inserted, the probe holder 4 is located near the opening 6 and connected to the warehouse wall 5, and the probe holder 4 is used to fix the probe in the warehouse Inside, the probe is placed in the irradiation area of the deep ultraviolet light generated by the deep ultraviolet light source 3, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Main peak wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com