Layered disinfection cabinet

A disinfection cabinet and disinfection chamber technology, applied in disinfection, sanitary equipment for toilets, cleaning equipment, etc., can solve the problems of inability to switch the disinfection mode of the upper and lower layers, inability to disinfect, etc., to achieve good disinfection effect and widen the effect of application scenarios

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

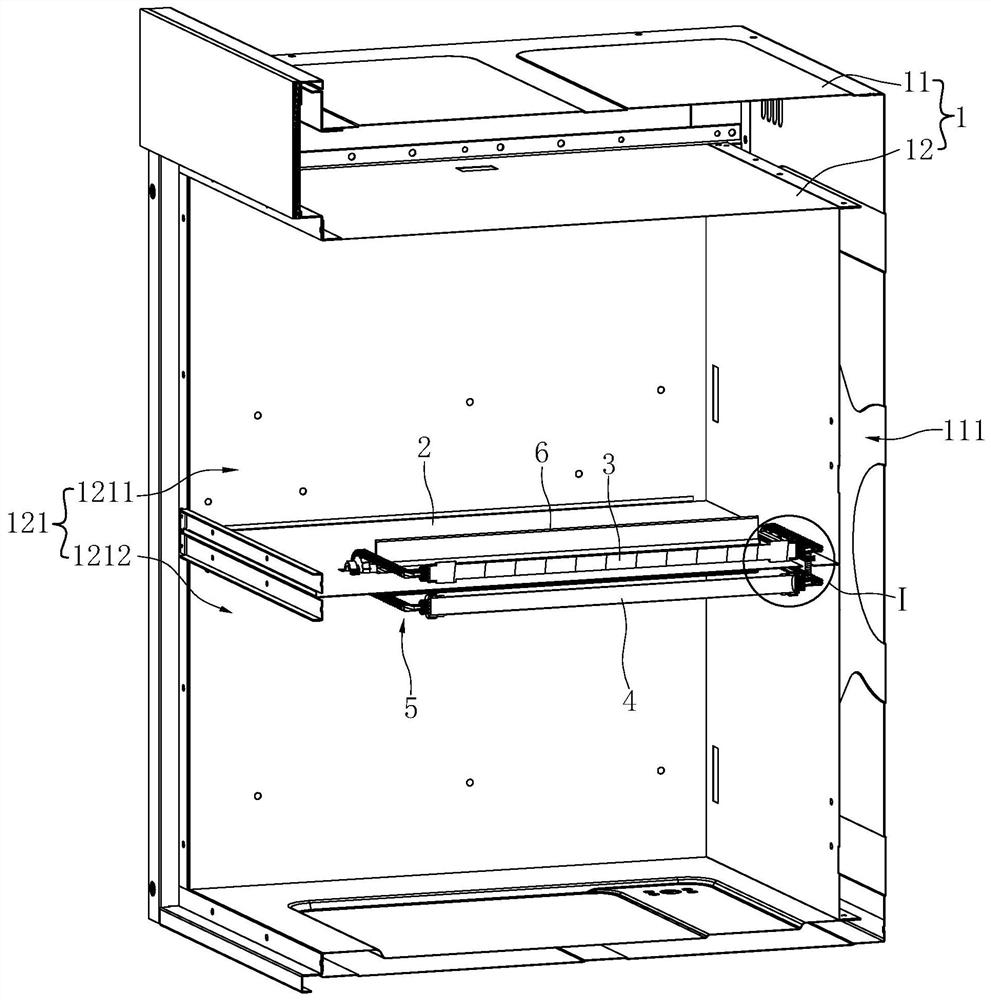

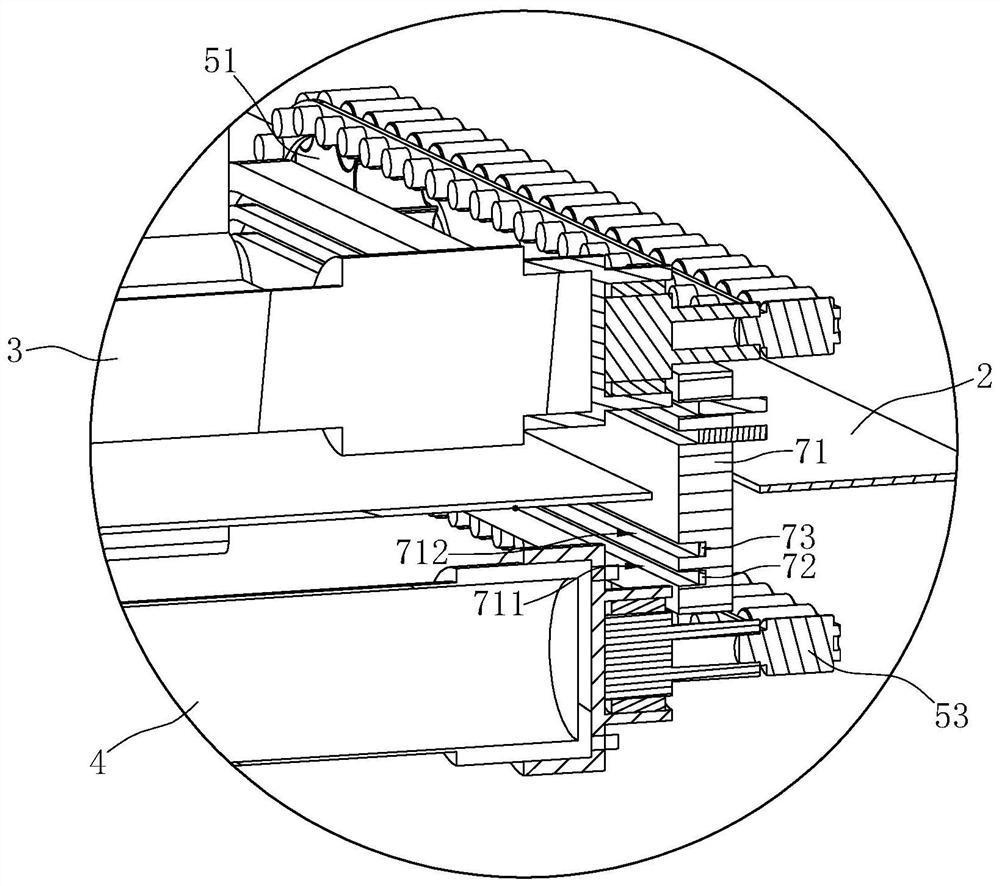

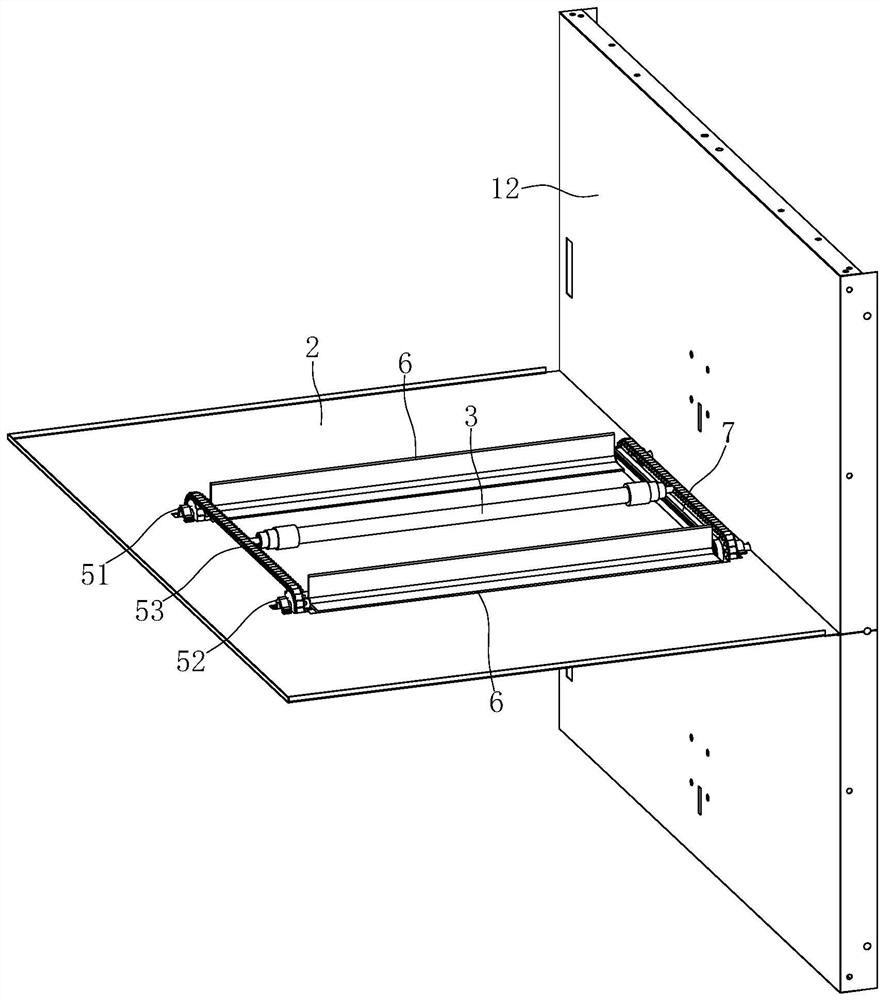

[0049] Such as Figure 1 to Figure 7 Shown is the first preferred embodiment of the layered disinfection cabinet of the present invention. The layered disinfection cabinet includes a cabinet body 1 , a partition plate 2 , a first disinfection device 3 , a second disinfection device 4 , a driving mechanism 5 , a shielding member 6 and a conductive device 7 .

[0050] Wherein, the cabinet 1 includes an outer shell 11 and an inner container 12 disposed in the outer shell 11 , the inner container 12 has a disinfection chamber 121 , and an interlayer 111 is formed between the outer wall of the inner container 12 and the inner wall of the outer shell 11 .

[0051] The partition plate 2 is basically arranged horizontally in the middle of the disinfection chamber 121, and divides the disinfection chamber 121 into a first chamber 1211 located above and a second chamber 1212 located below; An elongated opening 21 extending along the depth direction of the disinfection chamber 121 is op...

Embodiment 2

[0065] Such as Figure 8 Shown is the second preferred embodiment of the layered disinfection cabinet of the present invention. The difference with Example 1 is:

[0066] In this embodiment, the conductive device 7 is replaced by a conductive flexible wire 7'. The number of the flexible wires 7' is two, and they are installed on the top surface and the bottom surface of the partition plate 2 respectively. The first flexible wire 7' of the two flexible wires 7' One end is electrically connected to the power supply of the layered disinfection cabinet, and the second end is electrically connected to the terminals of the first disinfection device 3 and the second disinfection device 4 respectively. Since the length of the flexible wire 7' is constant, the driving mechanism 5 needs to drive the first sterilizing device 3 and the second sterilizing device 4 to move back and forth instead of moving in one direction all the time. In this embodiment, a conductive spring is used as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com