Symmetrical ring laser and manufacturing method thereof

A ring laser, symmetrical technology, applied in the direction of lasers, laser parts, phonon exciters, etc., can solve the problems that it is difficult to ensure the same state of the discharge surface and the difference in gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

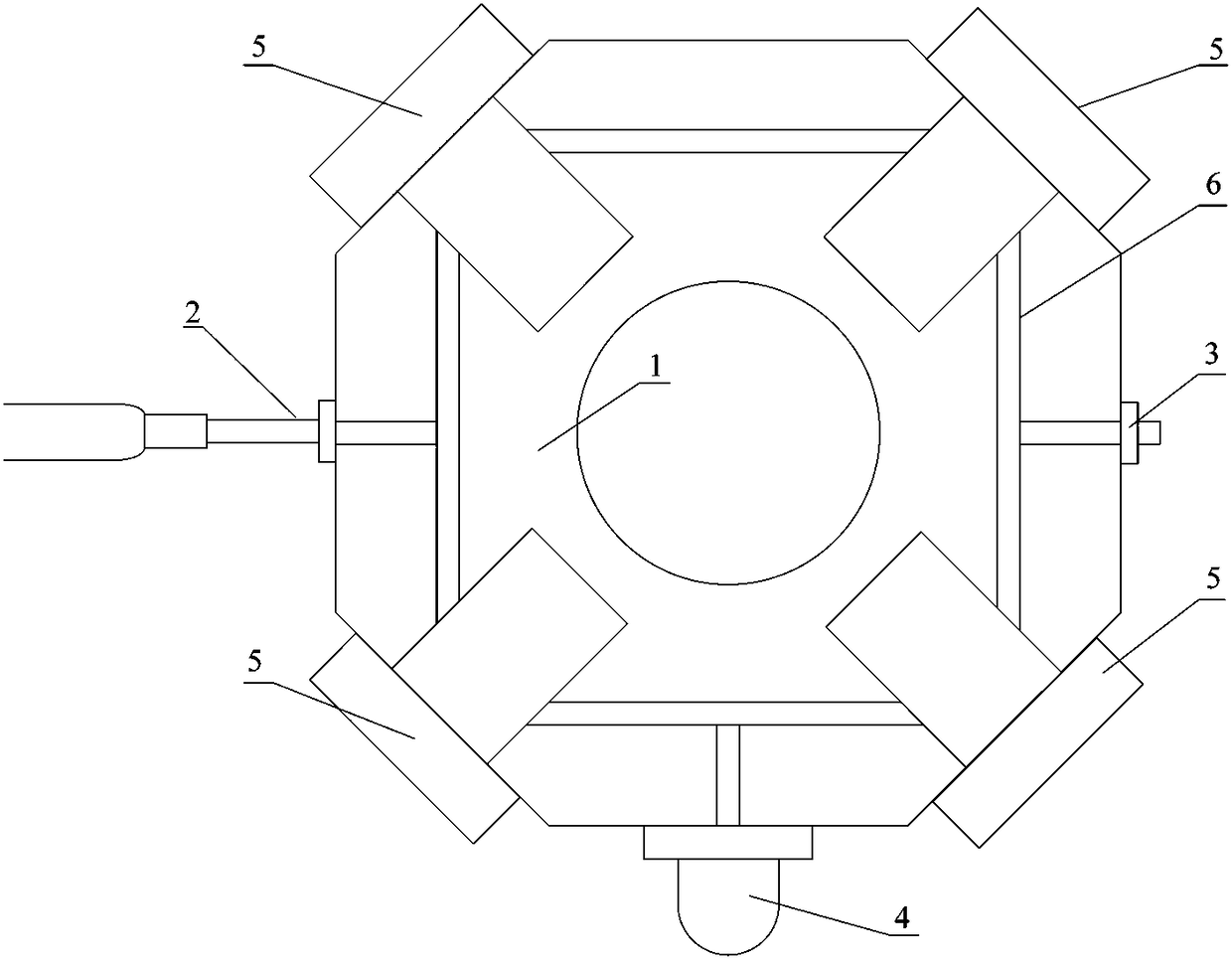

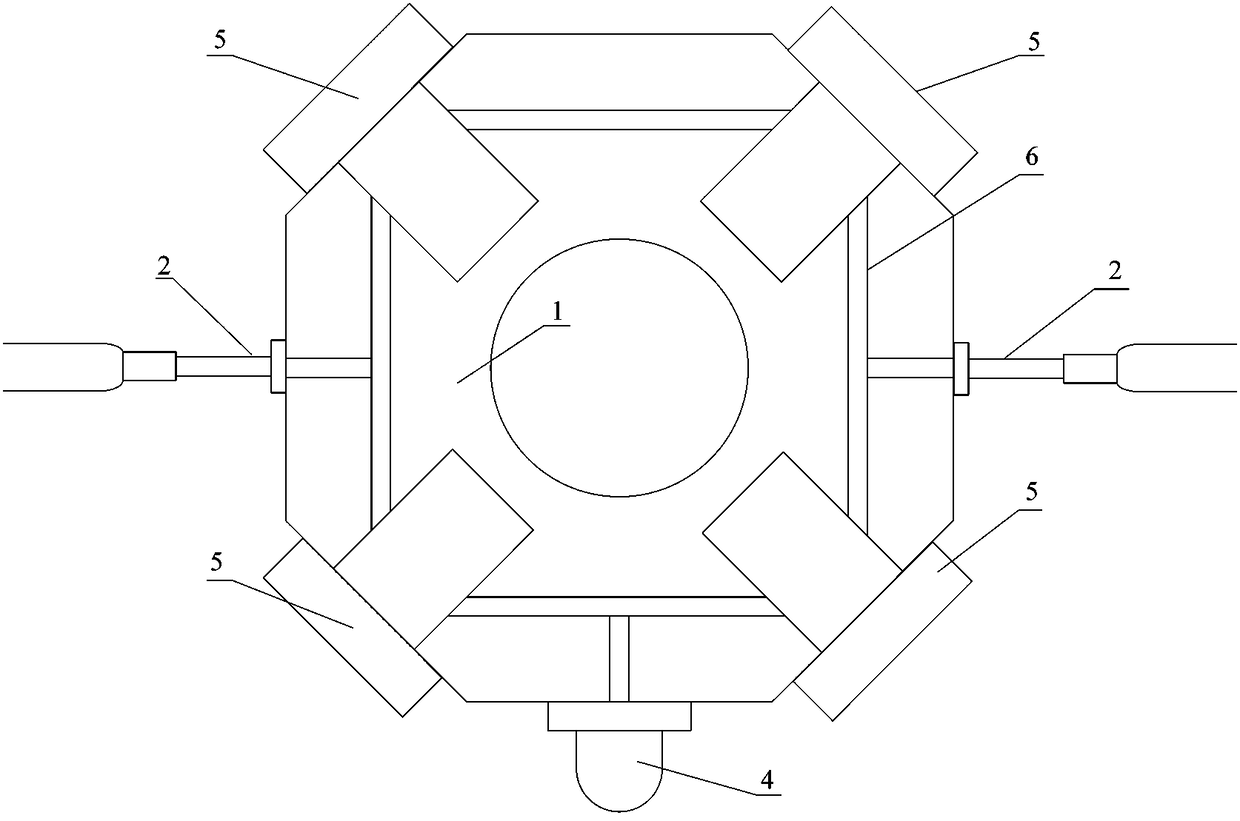

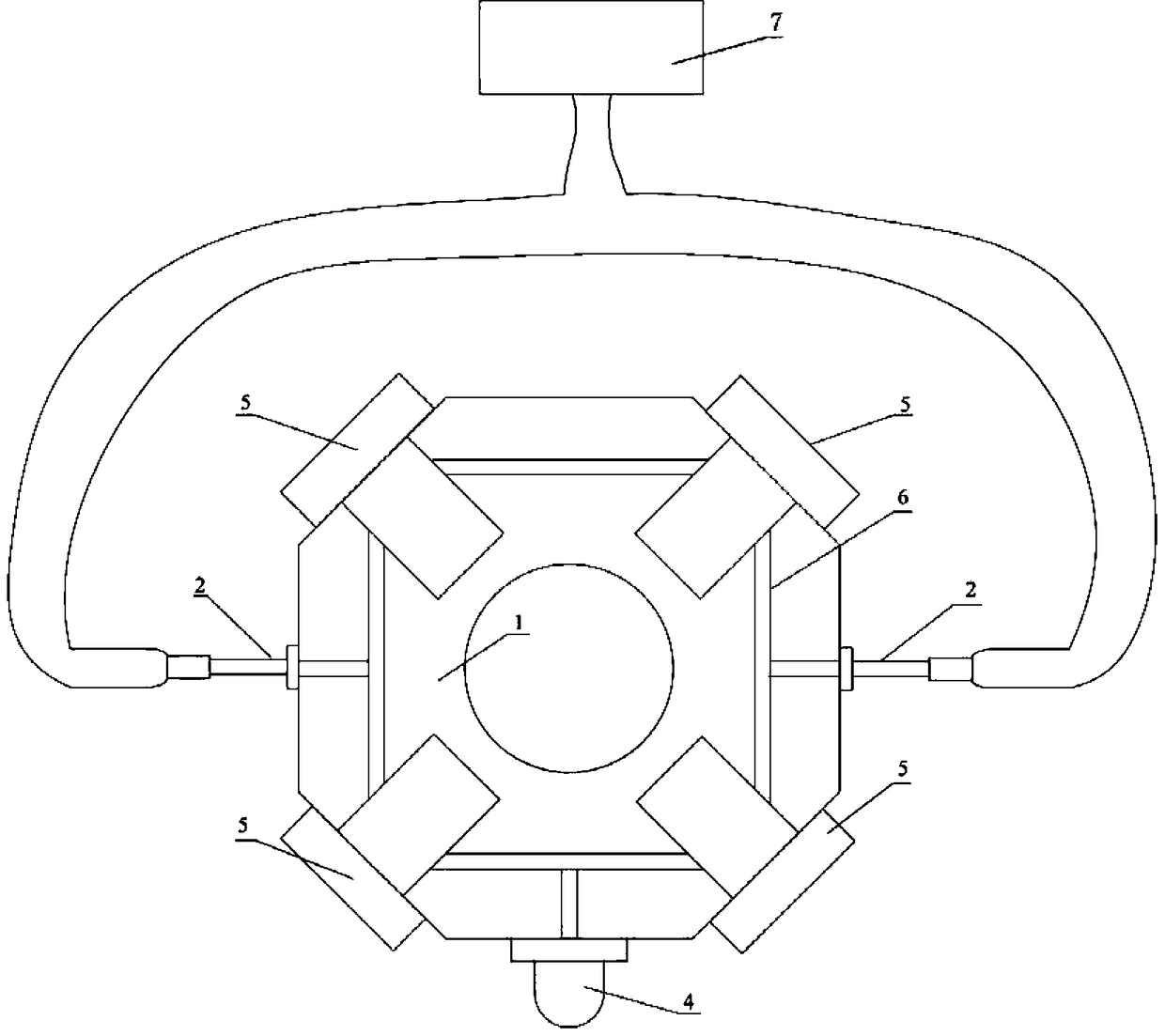

[0022] refer to Figure 1 to Figure 3 As shown, the present invention discloses a symmetrical ring laser, which includes a symmetrically arranged resonant cavity 1, a capillary 6 and four mirrors 5, and the lower end surface of the resonant cavity 1 is provided with a Cathode 4, two large anodes 2 located on another line of symmetry are symmetrically arranged on the left and right end faces of the resonant cavity 1, and the large anodes 2 include a titanium plate with holes 8, a copper tube 9, and a kovar tube 10 and glass tube 11. The present invention changes the existing electrode layout of large and small anodes and common cathodes of the existing ring laser into the layout of double large anodes and common cathodes. Described glass tube adopts DM308 glass tube.

[0023] The invention also discloses a manufacturing method of a symmetrical ring laser, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com