Constant pressure type gas flowmeter transfiguration chamber

A gas flow meter and chamber technology, which is applied in the direction of contraction/expansion chamber, etc., can solve the problems of measurement lower limit difference, dead space of oil chamber, bubbles into oil chamber, etc., so as to improve measurement accuracy, improve measurement accuracy, reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

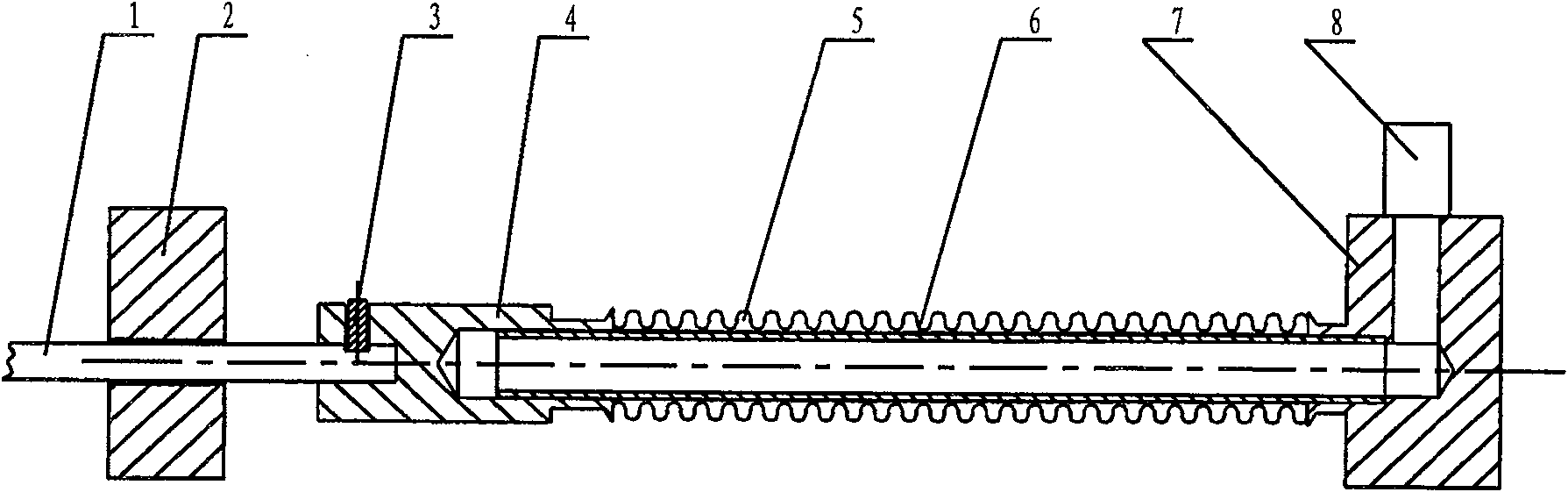

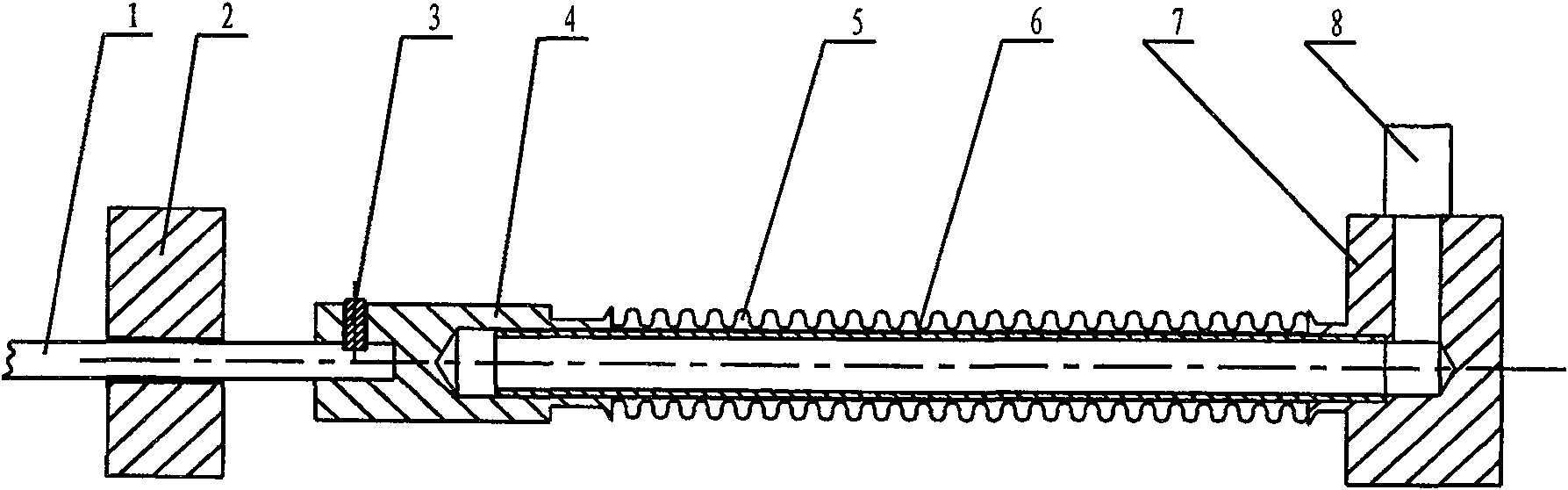

[0034] A variable volume chamber of a constant pressure gas flowmeter of the present invention includes a pull rod 1, a bracket 2, a pin 3, a moving block 4, a bellows 5, a guide rail cylinder 6, a fixed block 7 and a joint 8, all of which are made of stainless steel . Its connection relationship is:

[0035] The tie rod 1 is connected with the moving block 4 through the pin 3, the tie rod 1 is connected with the bracket 2, the two ends of the bellows 5 are respectively welded with the moving block 4 and the fixed block 7, and one end of the guide rail tube 6 is welded with the fixed block 7 in the bellows 5, The other end of the fixed block 7 is connected with the joint 8 .

[0036] Among them, the connection mode of the bellows 5, the guide rail tube 6, and the joint 8 with the fixed block 7 is: a through hole is processed inside the fixed block 7, and the bellows 5 and the guide rail tube 6 are fixed on the fixed block by welding 7 First, weld the guide rail cylinder 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com